Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL 1DZ

Engine

1DZ

Serial start-end

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

093500-2240 Fuel Injection Nozzle 4Pcs

DFGUFG [Product compatibility]: The OE number of this product is 093500-2240 || [Enhanced Fuel Efficiency & Power Output: Precision-engineered fuel injectors optimize spray patterns for improved combustion efficiency, directly boosting mileage while maintaining stable engine performance across all RPM ranges || [Easy to install and affordable]: Each fuel injector meets factory standard specifications, is simple and convenient to install, has higher combustion efficiency, and can effectively reduce fuel consumption || [High-quality materials for better performance]: The injectors are made of high-quality materials and advanced manufacturing processes to ensure durability and service life, allowing your engine to run smoothly for a long time || [Guaranteed Engine Performance]: This product is one of the key components of electronic fuel injection engines, helping to improve engine performance

DFGUFG [Product compatibility]: The OE number of this product is 093500-2240 || [Enhanced Fuel Efficiency & Power Output: Precision-engineered fuel injectors optimize spray patterns for improved combustion efficiency, directly boosting mileage while maintaining stable engine performance across all RPM ranges || [Easy to install and affordable]: Each fuel injector meets factory standard specifications, is simple and convenient to install, has higher combustion efficiency, and can effectively reduce fuel consumption || [High-quality materials for better performance]: The injectors are made of high-quality materials and advanced manufacturing processes to ensure durability and service life, allowing your engine to run smoothly for a long time || [Guaranteed Engine Performance]: This product is one of the key components of electronic fuel injection engines, helping to improve engine performance

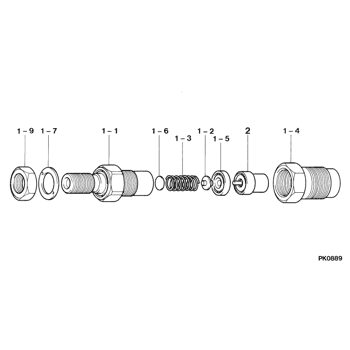

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-02240

HOLDER & NOZZLE SE

Include in ##:

Nozzle Specification:

Parts number

0935002240 TOYOTA

Nozzle

0934005010

First opm

11.27-12.25

First op

115-125

Second om

-

Second op

-

Torquen

34.3-39.2

Torque

3.5-4.0

Prelift

-

Max lift

Engine

BUS A/C 1C

Information

093500-2850 consists of 093500-2240 and a gasket.

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-02240

HOLDER & NOZZLE SE

Information:

Marine Engine Performance Analysis Report (PAR)

Today's marine user is concerned with performance, cost of operation and satisfactory engine life. Traditionally, vessel performance has been directly related to the propulsion engine, when in fact the engine is only one of numerous factors influencing the propulsion system.To verify the condition of the propulsion system, Caterpillar has developed the Marine Engine Performance Analysis Report (PAR) program. Marine Engine PAR is an in-vessel test procedure, performed and evaluated by Caterpillar certified Marine Analysts under normal or bollard operating conditions, comparing the performance of all marine engine systems to original factory test cell specifications.When Marine Engine PAR testing is conducted at Sea Trial, it can assure you of a quality installation that confirms hull, rudders, propeller, marine transmission, ventilation and cooling systems are all properly matched for optimum performance and fuel efficiency.Caterpillar additionally recommends regularly scheduled (see Maintenance Schedule) Marine Engine PAR analyses to maintain optimum performance. Periodic PAR analyses can define propulsion system deterioration and aid in fine tuning the maintenance, repair and overhaul schedules, which will provide you the most economical and efficient cost of operation.

Today's marine user is concerned with performance, cost of operation and satisfactory engine life. Traditionally, vessel performance has been directly related to the propulsion engine, when in fact the engine is only one of numerous factors influencing the propulsion system.To verify the condition of the propulsion system, Caterpillar has developed the Marine Engine Performance Analysis Report (PAR) program. Marine Engine PAR is an in-vessel test procedure, performed and evaluated by Caterpillar certified Marine Analysts under normal or bollard operating conditions, comparing the performance of all marine engine systems to original factory test cell specifications.When Marine Engine PAR testing is conducted at Sea Trial, it can assure you of a quality installation that confirms hull, rudders, propeller, marine transmission, ventilation and cooling systems are all properly matched for optimum performance and fuel efficiency.Caterpillar additionally recommends regularly scheduled (see Maintenance Schedule) Marine Engine PAR analyses to maintain optimum performance. Periodic PAR analyses can define propulsion system deterioration and aid in fine tuning the maintenance, repair and overhaul schedules, which will provide you the most economical and efficient cost of operation.