Rating:

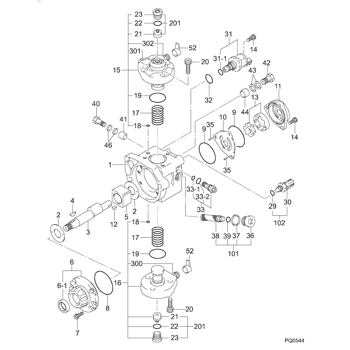

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL V3800DI

Engine

V3800DI

Serial start-end

1111-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$535.00

09 Nov 2024

CN: HIRINTOL-shop

294000-1720 1J500-50501 1J500-50503 294000-1721 294000-1722 294000-1723 HP3 CR Injection Pump for Kubota V3800 V3800DI Engine SVL90-2 EC140D Excavator Bobcat T750 T770 T870 Loader

HIRINTOL 🔸Replace Part Number: 294000-1720, 1J500-50501, 1J500-50503, 294000-1721, 294000-1722, 294000-1723, 294000-1724. || 🔸Compatible Model: For Kubota V3800 V3800DI Engine SVL90-2 EC140D Excavator Bobcat T750 T770 T870 Loader. || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

HIRINTOL 🔸Replace Part Number: 294000-1720, 1J500-50501, 1J500-50503, 294000-1721, 294000-1722, 294000-1723, 294000-1724. || 🔸Compatible Model: For Kubota V3800 V3800DI Engine SVL90-2 EC140D Excavator Bobcat T750 T770 T870 Loader. || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

$1,078.76

09 Nov 2024

CN: QINGCANG Constructio

Qiape Fuel Injection Pump 294000-1720 1J500-50501 Compatible with Kubota M8560 SVL90-2 V3800

Qiape Part Name: 294000-1720 1J500-50501 Fuel Injection Pump || Part Number: 294000-1720 1J500-50501 2940001720 1J50050501 || Compatible with Kubota M8560 Tractor || Compatible with Kubota SVL90-2 Loader || Compatible with Kubota V3800 Engine

Qiape Part Name: 294000-1720 1J500-50501 Fuel Injection Pump || Part Number: 294000-1720 1J500-50501 2940001720 1J50050501 || Compatible with Kubota M8560 Tractor || Compatible with Kubota SVL90-2 Loader || Compatible with Kubota V3800 Engine

$491.00

09 Nov 2024

CN: SHESWEET ENGINE PART

SHESWEET Fuel Injection Pump 294000-1720 2940001720 For Kubota V3800 Engine Excavator SVL90-2 EC140D

SHESWEET Part Number: 294000-1720 2940001720 || Part Name: Fuel Injection Pump || Compatible with Kubota Engine V3800 Excavator SVL90-2 EC140D || If any question,Please tell us! || NOTE:Please leave a message after purchasing the product and let us know your Engine nameplate or Part number,We will help you confirm it and make sure it is the product you want.

SHESWEET Part Number: 294000-1720 2940001720 || Part Name: Fuel Injection Pump || Compatible with Kubota Engine V3800 Excavator SVL90-2 EC140D || If any question,Please tell us! || NOTE:Please leave a message after purchasing the product and let us know your Engine nameplate or Part number,We will help you confirm it and make sure it is the product you want.

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29400-01720

PUMP ASSY, SUPPLY

HP3

1J500-50501

KUBOTA

Include in ##:

29400-01720

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29400-01720

1J500-5050

PUMP ASSY, SUPPLY

2940001720

1J500-50501

KUBOTA

PUMP ASSY, SUPPLY

2940001720

1J500-50502

KUBOTA

PUMP ASSY, SUPPLY

2940001720

1J500-50503

KUBOTA

PUMP ASSY, SUPPLY

2940001720

1J500-50504

KUBOTA

PUMP ASSY, SUPPLY

2940001720

1J500-50505

KUBOTA

PUMP ASSY, SUPPLY

Information:

Start By:a. remove governor**See Disassemble Governor story

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove the bolts and the plate from the side of the fuel injection pump housing. 2. Install tool (A) in the fuel injection pump housing. Move the rack until tool (A) can be installed to hold the rack in the center position to remove the fuel injection pumps.3. Use tool (B) to remove bushing (1).4. Remove the O-ring seal from the fuel injection pump housing. 5. Install tool (C) on the bonnet and remove the fuel injection pump. 6. Remove spacer (2). Keep the spacers (2) from the fuel injection pumps together with identification as to their location in the pump housing.7. Perform steps 3 through 6 to remove the other fuel injection pumps. The following steps are to install the fuel injection pumps.8. Install spacer (2).9. Install tool (A). Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.10. Turn camshaft until the lobe of the camshaft is down for the pump to be installed.11. Install tool (C) on the bonnet on the fuel injection pump.12. Install the fuel injection pump in the pump housing with saw cut slot in the gear in alignment with the small pin and groove in the barrel in alignment with dowel in the pump housing.13. Put clean oil on O-ring seal and install it in the fuel injection pump housing.14. Install the bushing by hand until the bushing is even with the top of the housing. If the bushing can not be installed this far by hand, remove it. Remove the fuel injection pump ad put the pump in alignment again and install the bushing again.15. Install tool (B) on the bushing and tighten the bushing to a torque of 190 14 N m (140 10 lb ft).16. Install tooling (D) to measure total rack travel. Correct rack travel is 15.7 mm (.618 in). A smaller measurement is an indication of improper fuel injection pump installation.17. Perform Steps 1 through 9 to install the other fuel pumps18. Install the cover and gasket on the fuel injection pump housing.End By:a. install governor**See Assemble Governor storyDisassemble And Assemble Fuel Injection Pumps

Start By:a. remove fuel injection pumps

When the injection pumps are disassembled, handle the parts carefully. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not intermix the plunger of one pump in the barrel with another pump. If one part is worn, install a complete new pump assembly. Be careful when placing the plunger into the bore of the barrel.

1. Pull plunger (1) and washer (5) out of barrel (3) and spring (2).

Do not remove the gear from the plunger.

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove the bolts and the plate from the side of the fuel injection pump housing. 2. Install tool (A) in the fuel injection pump housing. Move the rack until tool (A) can be installed to hold the rack in the center position to remove the fuel injection pumps.3. Use tool (B) to remove bushing (1).4. Remove the O-ring seal from the fuel injection pump housing. 5. Install tool (C) on the bonnet and remove the fuel injection pump. 6. Remove spacer (2). Keep the spacers (2) from the fuel injection pumps together with identification as to their location in the pump housing.7. Perform steps 3 through 6 to remove the other fuel injection pumps. The following steps are to install the fuel injection pumps.8. Install spacer (2).9. Install tool (A). Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.10. Turn camshaft until the lobe of the camshaft is down for the pump to be installed.11. Install tool (C) on the bonnet on the fuel injection pump.12. Install the fuel injection pump in the pump housing with saw cut slot in the gear in alignment with the small pin and groove in the barrel in alignment with dowel in the pump housing.13. Put clean oil on O-ring seal and install it in the fuel injection pump housing.14. Install the bushing by hand until the bushing is even with the top of the housing. If the bushing can not be installed this far by hand, remove it. Remove the fuel injection pump ad put the pump in alignment again and install the bushing again.15. Install tool (B) on the bushing and tighten the bushing to a torque of 190 14 N m (140 10 lb ft).16. Install tooling (D) to measure total rack travel. Correct rack travel is 15.7 mm (.618 in). A smaller measurement is an indication of improper fuel injection pump installation.17. Perform Steps 1 through 9 to install the other fuel pumps18. Install the cover and gasket on the fuel injection pump housing.End By:a. install governor**See Assemble Governor storyDisassemble And Assemble Fuel Injection Pumps

Start By:a. remove fuel injection pumps

When the injection pumps are disassembled, handle the parts carefully. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not intermix the plunger of one pump in the barrel with another pump. If one part is worn, install a complete new pump assembly. Be careful when placing the plunger into the bore of the barrel.

1. Pull plunger (1) and washer (5) out of barrel (3) and spring (2).

Do not remove the gear from the plunger.