Rating:

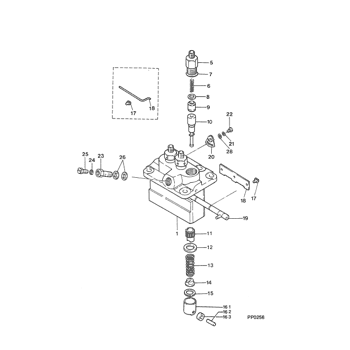

Information pump assy, injecti Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

ZGZJYBL Fuel Injection Pump for Kubota D1100 Engine 094500-0612 0945000612

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:094500-0612, 0945000612 || Application:For Kubota D1100 Engine || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:094500-0612, 0945000612 || Application:For Kubota D1100 Engine || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

HESIEU 094500-0612 0945000612 Fuel Injection Pump compatible with Kubota D1100 Engine

HESIEU Replace Part Number: 094500-0612, 0945000612 || Application fis for: For Kubota D1100 Engine || Application fis for: For Kubota D1100 Engine || The Package Included: 1x Fuel Injection Pump || Warranty: 1 Year

HESIEU Replace Part Number: 094500-0612, 0945000612 || Application fis for: For Kubota D1100 Engine || Application fis for: For Kubota D1100 Engine || The Package Included: 1x Fuel Injection Pump || Warranty: 1 Year

Compatible with Kubota D1100 Engine Fuel Injection Pump 094500-0612 0945000612

KoovDem Part Name :Fuel Injection Pump || Part Number:094500-0612 0945000612 || This product is designed to work seamlessly with the Kubota D1100 Engine, offering reliable and efficient performance for industrial and agricultural applications. Built to withstand heavy-duty use in construction equipment, generators, and other machinery, it ensures smooth operation and maximum productivity. Trust in this product for consistent power and durability for your Kubota D1100 Engine needs. || Accurate - To prevent unnecessary returns, it is important to refer to the old part number and machine model when ordering the correct product. If unsure, please contact us for assistance as we are committed to providing excellent customer service. || Our products are designed and tested to ensure reliable performance. With high reliability and stability, they can maintain optimal working conditions for extended periods of time.

KoovDem Part Name :Fuel Injection Pump || Part Number:094500-0612 0945000612 || This product is designed to work seamlessly with the Kubota D1100 Engine, offering reliable and efficient performance for industrial and agricultural applications. Built to withstand heavy-duty use in construction equipment, generators, and other machinery, it ensures smooth operation and maximum productivity. Trust in this product for consistent power and durability for your Kubota D1100 Engine needs. || Accurate - To prevent unnecessary returns, it is important to refer to the old part number and machine model when ordering the correct product. If unsure, please contact us for assistance as we are committed to providing excellent customer service. || Our products are designed and tested to ensure reliable performance. With high reliability and stability, they can maintain optimal working conditions for extended periods of time.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09450-00612

15321-5101

PUMP ASSY, INJECTI

Information:

Obtain Oil Sample Every 250 Hour Interval (T & TA) or Every 500 Hour Interval (NA).Obtain S O S samples at regularly scheduled intervals to monitor the condition and maintenance requirements of your engine. Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the engine crankcase.Consult your Caterpillar dealer for complete information and assistance in establishing an S O S analysis program for your engine(s).S O S Analysis

S O S analysis is composed of three basic tests: * Wear Analysis* Chemical and Physical Tests* Oil Condition Analysis Wear analysis is performed with an atomic absorption spectrophotometer to monitor component wear by identifying and measuring concentrations, in parts per million, of wear elements present in the oil. Based on known normal concentration data, maximum limits of wear elements are established. Impending failures can be identified when test results deviate from concentration levels established as acceptable, based on normal wear. Chemical and physical tests detect the presence of water, fuel and glycol (antifreeze) in the oil and determine whether or not their concentrations exceed established maximum limits. Oil condition is evaluated with infrared analysis. This test determines the presence and measures the amount of contaminants such as soot, sulfur products, oxidation, and nitration products in the oil. Infrared analysis can also assist in customizing (reducing, maintaining or extending) oil change intervals for particular conditions and applications.Infrared analysis should always be accompanied by wear element analysis and chemical and physical tests to assure accurate diagnosis. Infrared analysis must be used to determine oil change intervals. S O S analysis must include Infrared (IR) in the analysis.The test results of the oil samples will then be used as a basis for determining the oil change interval for your engine, giving you the ultimate time between oil changes without the risk of engine damage.Refer to Caterpillar pamphlet Listen To Your Oil (PEDP1129) for information and benefits of S O S analysis.

S O S analysis is composed of three basic tests: * Wear Analysis* Chemical and Physical Tests* Oil Condition Analysis Wear analysis is performed with an atomic absorption spectrophotometer to monitor component wear by identifying and measuring concentrations, in parts per million, of wear elements present in the oil. Based on known normal concentration data, maximum limits of wear elements are established. Impending failures can be identified when test results deviate from concentration levels established as acceptable, based on normal wear. Chemical and physical tests detect the presence of water, fuel and glycol (antifreeze) in the oil and determine whether or not their concentrations exceed established maximum limits. Oil condition is evaluated with infrared analysis. This test determines the presence and measures the amount of contaminants such as soot, sulfur products, oxidation, and nitration products in the oil. Infrared analysis can also assist in customizing (reducing, maintaining or extending) oil change intervals for particular conditions and applications.Infrared analysis should always be accompanied by wear element analysis and chemical and physical tests to assure accurate diagnosis. Infrared analysis must be used to determine oil change intervals. S O S analysis must include Infrared (IR) in the analysis.The test results of the oil samples will then be used as a basis for determining the oil change interval for your engine, giving you the ultimate time between oil changes without the risk of engine damage.Refer to Caterpillar pamphlet Listen To Your Oil (PEDP1129) for information and benefits of S O S analysis.