Rating:

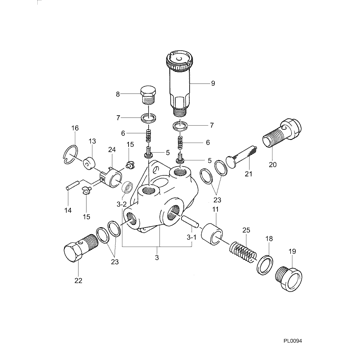

Information pump assy, fuel fe Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09210-00342

PUMP ASSY, FUEL FE

KE

6 065 1501 01

HINO

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09210-00342

6 065 1501

PUMP ASSY, FUEL FE

Information:

Disassembly and Inspection of Starter

Inspection of Starter

(1) Armature coil short-circuit testPlace the armature on the growler. Set an iron piece parallel to the armature, and rotate the armature slowly by hand. If the iron piece is attracted to the coil or vibrates, there is a short-circuit; replace the armature.

Armature coil short-circuit test(2) Armature coil grounding testIf there is continuity between the commutator and shaft (or core), replace the armature.

Armature coil grounding test(3) Measurement of commutator runoutMeasure the commutator runout using a dial gage. If the amount of runout exceeds the limit value, replace the armature. If the commutator surface is rough, refinish the surface with sand paper (#300 to #500). If the surface has ridges due to abrasion, replace the armature since it is not repairable.

Measurement of commutator runout(4) Measurement of commutator outside diameterMeasure the outside diameter of the commutator, and, if the limit is exceeded, replace the armature.

Measurement of commutator outside diameter(5) Measurement of mold depth between segmentsClean the grooves between segments, and measure the mold depths between segments. If the limit value is exceeded, repair. (6) Inspection of armature gearIf the inspection of the armature gear finds abnormal wearing or chipped teeth, replace the armature.

Measurement of mold depth between segments(7) Yoke coil open-circuit testCheck to see if there is continuity between the terminal lead wire and brush (positive). If there is no continuity, there is an open-circuit; replace the yoke assembly.

Yoke coil open-circuit test(8) Yoke coil grounding testCheck to see if there is continuity between the yoke and brush (positive). If there is continuity, the yoke coil is grounded. Check the insulation, and replace the yoke assembly if the problem cannot be corrected.

Yoke coil grounding test(9) Inspection of magnetic switchConduct the following the following continuity tests, and, if there is any problem, replace the magnetic switch.(a) Coil open-circuit testCheck to see if there is continuity between terminal M and ground (case). There should be no continuity between terminal B and ground.(b) Inspection of contact adhesionCheck to make sure there is no continuity between terminal B and terminal M.

Inspection of magnetic switch(10) Measurement of brush lengthMeasure the length of each brush, and, if the limit value is exceeded, replace the brush. If the brush is unevenly worn or has a rough contact surface, refinish with sand paper (#300 to #500).

Measurement of brush length(11) Measurement of brush spring tensionMeasure the installation tension of each brush spring. Read the tension at the moment when the spring detaches from the brush. If the tension value is near the limit value, replace the brush spring.

Measurement of brush spring tension(12) Inspection of brush holders for insulationUsing a tester, check to make sure that there is no continuity between the positive-side brush holder and negative-side brush holder plate. If there is continuity, replace the brush holder.

Inspection of brush holder for insulation(13) Inspection of overrunning clutchMake sure that the pinion shaft rotates smoothly in one direction, and locks in place when it is turned in the opposite direction. If the pinion shaft does not

Inspection of Starter

(1) Armature coil short-circuit testPlace the armature on the growler. Set an iron piece parallel to the armature, and rotate the armature slowly by hand. If the iron piece is attracted to the coil or vibrates, there is a short-circuit; replace the armature.

Armature coil short-circuit test(2) Armature coil grounding testIf there is continuity between the commutator and shaft (or core), replace the armature.

Armature coil grounding test(3) Measurement of commutator runoutMeasure the commutator runout using a dial gage. If the amount of runout exceeds the limit value, replace the armature. If the commutator surface is rough, refinish the surface with sand paper (#300 to #500). If the surface has ridges due to abrasion, replace the armature since it is not repairable.

Measurement of commutator runout(4) Measurement of commutator outside diameterMeasure the outside diameter of the commutator, and, if the limit is exceeded, replace the armature.

Measurement of commutator outside diameter(5) Measurement of mold depth between segmentsClean the grooves between segments, and measure the mold depths between segments. If the limit value is exceeded, repair. (6) Inspection of armature gearIf the inspection of the armature gear finds abnormal wearing or chipped teeth, replace the armature.

Measurement of mold depth between segments(7) Yoke coil open-circuit testCheck to see if there is continuity between the terminal lead wire and brush (positive). If there is no continuity, there is an open-circuit; replace the yoke assembly.

Yoke coil open-circuit test(8) Yoke coil grounding testCheck to see if there is continuity between the yoke and brush (positive). If there is continuity, the yoke coil is grounded. Check the insulation, and replace the yoke assembly if the problem cannot be corrected.

Yoke coil grounding test(9) Inspection of magnetic switchConduct the following the following continuity tests, and, if there is any problem, replace the magnetic switch.(a) Coil open-circuit testCheck to see if there is continuity between terminal M and ground (case). There should be no continuity between terminal B and ground.(b) Inspection of contact adhesionCheck to make sure there is no continuity between terminal B and terminal M.

Inspection of magnetic switch(10) Measurement of brush lengthMeasure the length of each brush, and, if the limit value is exceeded, replace the brush. If the brush is unevenly worn or has a rough contact surface, refinish with sand paper (#300 to #500).

Measurement of brush length(11) Measurement of brush spring tensionMeasure the installation tension of each brush spring. Read the tension at the moment when the spring detaches from the brush. If the tension value is near the limit value, replace the brush spring.

Measurement of brush spring tension(12) Inspection of brush holders for insulationUsing a tester, check to make sure that there is no continuity between the positive-side brush holder and negative-side brush holder plate. If there is continuity, replace the brush holder.

Inspection of brush holder for insulation(13) Inspection of overrunning clutchMake sure that the pinion shaft rotates smoothly in one direction, and locks in place when it is turned in the opposite direction. If the pinion shaft does not