Rating:

Information key, woodruff Denso

Include in ##:

09200-02370

as KEY, WOODRUFF

Cross reference number

Part num

Firm num

Firm

Name

94913-00320

KEY, WOODRUFF

Information:

Excavator Application ENGINE MODEL AND ENGINE NUMBER

Model, Classification, and Use

Engine model embossment and engine number stamp

(1) Embossment of engine model and cylinder volumeThe engine model and cylinder volume are embossed on the side of injection pump mounting portion of the cylinder block.

Engine Model and Cylinder Volume(2) Engine number stampThe engine number is stamped on the injection pump mounting portion of the cylinder block (on the upper side of the tie rod cover).It is a serial number beginning with 1001 as shown below.

Engine NumberSECTIONAL VIEWS

Longitudinal Section (L3C)

Cross Section (L3C)

Sectional Views of Governor (L3C)

Oil Pump and Oil FilterFEATURES

1. Aim of developmentThe L series aim at the through going compact, lightweight engines which are suitable for superseding gasoline engines to power lawn mowers, vehicles, etc. The high-speed (3600 rpm continuous) specification engines are also available to apply them to the generators, welders, and marine use. The L series are the smallest and lightest water-cooled diesel engines in the world.2. Features of the new series(1) Small and lightweight engineThe new L series are 10 to 20% smaller in weight and 15 to 20% smaller in contour volume than the same class of engines of competitors.(2) Low noise and economical fuel consumptionLow noise and economical fuel consumption are attained by the well designed cylinder block construction (having curved side faces), the rearranged combustion chambers, and the small-sized fuel injection system.

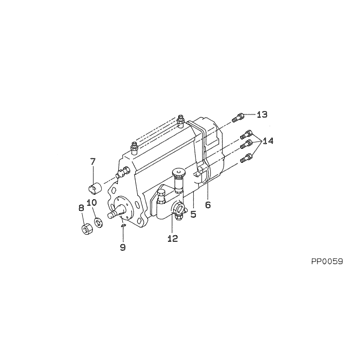

Injection Pump(3) Easy startingThe engine can be started instantly only by keeping the starting switch key in the ON position for about 6 seconds to allow automatic feeding of current to the glow plugs, eliminating the necessity of setting the key to the HEAT position. (For engines with the automatic glow plug system.)The new governor mechanism also contributes to easy engine start, because it increases fuel injection and delays injection timing for easy engine start without necessity of moving the throttle lever to the "full throttle" position.(4) Multipurpose engineThe L series engine can be equipped with various kinds of optional devices.

Nozzle Holders and Return PipePerformance Curves

L2 Series Performance Curves

L2A

L2C

L2EDIN 6270 : NETBarometric pressure : 736mmHgAmbient temperature : 20°CVapor pressure : 10.5mmHgL3 Series Performance Curves

L3A

L3C

L3CDIN 6270 : NETBarometric pressure : 736mmHgAmbient temperature : 20°CVapor pressure : 10.5mmHgENGINE SPECIFICATIONS

MAINTENANCE

Engine oil and oil filter

1. Checking and correcting the engine oil level.(1) Place the engine horizontally.(2) Check the oil level with the oil level gauge. If the oil level has fallen to the lower limit, add oil up to the upper limit.(3) Check the oil level before (everyday) operation of the engine. CAUTION* Whenever oil is added, check the oil level again after waiting for about 1 minute.* When adding oil, use only the same engine oil as used in the engine.* When checking the oil level in an engine which has been long out of use, run the engine for several minutes, stop the engine, and check the oil level after a while.

Checking Oil Level

Oil Level Gauge2. Oil change intervalsChange the oil after initial 50-hour operation of a new engine and, thereafter, every 100 hours of operation.Replace

Model, Classification, and Use

Engine model embossment and engine number stamp

(1) Embossment of engine model and cylinder volumeThe engine model and cylinder volume are embossed on the side of injection pump mounting portion of the cylinder block.

Engine Model and Cylinder Volume(2) Engine number stampThe engine number is stamped on the injection pump mounting portion of the cylinder block (on the upper side of the tie rod cover).It is a serial number beginning with 1001 as shown below.

Engine NumberSECTIONAL VIEWS

Longitudinal Section (L3C)

Cross Section (L3C)

Sectional Views of Governor (L3C)

Oil Pump and Oil FilterFEATURES

1. Aim of developmentThe L series aim at the through going compact, lightweight engines which are suitable for superseding gasoline engines to power lawn mowers, vehicles, etc. The high-speed (3600 rpm continuous) specification engines are also available to apply them to the generators, welders, and marine use. The L series are the smallest and lightest water-cooled diesel engines in the world.2. Features of the new series(1) Small and lightweight engineThe new L series are 10 to 20% smaller in weight and 15 to 20% smaller in contour volume than the same class of engines of competitors.(2) Low noise and economical fuel consumptionLow noise and economical fuel consumption are attained by the well designed cylinder block construction (having curved side faces), the rearranged combustion chambers, and the small-sized fuel injection system.

Injection Pump(3) Easy startingThe engine can be started instantly only by keeping the starting switch key in the ON position for about 6 seconds to allow automatic feeding of current to the glow plugs, eliminating the necessity of setting the key to the HEAT position. (For engines with the automatic glow plug system.)The new governor mechanism also contributes to easy engine start, because it increases fuel injection and delays injection timing for easy engine start without necessity of moving the throttle lever to the "full throttle" position.(4) Multipurpose engineThe L series engine can be equipped with various kinds of optional devices.

Nozzle Holders and Return PipePerformance Curves

L2 Series Performance Curves

L2A

L2C

L2EDIN 6270 : NETBarometric pressure : 736mmHgAmbient temperature : 20°CVapor pressure : 10.5mmHgL3 Series Performance Curves

L3A

L3C

L3CDIN 6270 : NETBarometric pressure : 736mmHgAmbient temperature : 20°CVapor pressure : 10.5mmHgENGINE SPECIFICATIONS

MAINTENANCE

Engine oil and oil filter

1. Checking and correcting the engine oil level.(1) Place the engine horizontally.(2) Check the oil level with the oil level gauge. If the oil level has fallen to the lower limit, add oil up to the upper limit.(3) Check the oil level before (everyday) operation of the engine. CAUTION* Whenever oil is added, check the oil level again after waiting for about 1 minute.* When adding oil, use only the same engine oil as used in the engine.* When checking the oil level in an engine which has been long out of use, run the engine for several minutes, stop the engine, and check the oil level after a while.

Checking Oil Level

Oil Level Gauge2. Oil change intervalsChange the oil after initial 50-hour operation of a new engine and, thereafter, every 100 hours of operation.Replace