Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

Construction machine 4M40

Engine

4M40

Serial start-end

9709-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$165.00

22 Feb 2024

CN: Xuan Chen Part

4 Pcs Fuel Injector 093500-6900 ME108408 for Mitsubishi Engine 4M40

SEBAOFADANSIOS part number:093500-6900 ME108408 || Applications:for Mitsubishi Engine 4M40

SEBAOFADANSIOS part number:093500-6900 ME108408 || Applications:for Mitsubishi Engine 4M40

$159.79

22 Feb 2024

CN: QYWD

ME108408 093500-6900 4 Pcs Fuel Injector for Mitsubishi Engine 4M40

TUWODE Part Number: 093500-6900 || Part Name:Fuel Injector || Application: Compatible with Mitsubishi Engine 4M40 || Installation is straightforward and does not necessitate any commissioning. || Consumes less fuel and prolongs the service life.

TUWODE Part Number: 093500-6900 || Part Name:Fuel Injector || Application: Compatible with Mitsubishi Engine 4M40 || Installation is straightforward and does not necessitate any commissioning. || Consumes less fuel and prolongs the service life.

$151.79

22 Feb 2024

CN: QYWD

4PCS Fuel Injector 093500-6900 0935006900 for Mitsubishi Diesel Engine 4M40

TUWODE Part Number:093500-6900 0935006900 || Part Name:Fuel Injector || Application: Compatible with Mitsubishi Diesel Engine 4M40 || Installation is straightforward and does not necessitate any commissioning. || Consumes less fuel and prolongs the service life.

TUWODE Part Number:093500-6900 0935006900 || Part Name:Fuel Injector || Application: Compatible with Mitsubishi Diesel Engine 4M40 || Installation is straightforward and does not necessitate any commissioning. || Consumes less fuel and prolongs the service life.

You can buy:

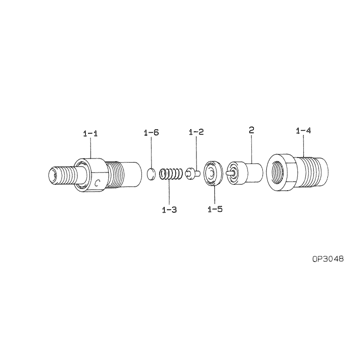

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-06900

HOLDER & NOZZLE SE

Include in ##:

09350-06900

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935006900 MITSUBISHI

Nozzle

0934006820

First opm

11.27-12.25

First op

115-125

Second om

Second op

Torquen

44.1-49.0

Torque

4.5-5.0

Prelift

-

Max lift

Engine

Construction machine 4M40

Information

Cross reference number

Part num

Firm num

Firm

Name

09350-06900

HOLDER & NOZZLE SE

Information:

Secure engine in swivelling mounting stand.1. Dismantle the following units and components: Air filter with holder, starter, air compressor with bracket and lubricating oil line, generator with holder, fuel-supply line to the flame-type heater plug or the pipe connecting with the pilot injector, induction manifold, exhaust manifold, cover plate on the exit air side, air cowling, fuel and lubricating oil filters with their supply lines, leak-off and delivery lines, vertical plate on the fly-wheel side, blower, front vertical plate, oil cooler, air cowling, vee-belt idler.

9-13 Immediately fuel line unions are dismantled plug or fit caps on the connecting stubs and pipe ends.Fig. 9-13

9-142. Dismantle the vee-belt pulley for the air compressor, main belt pulley and front cover. (Use retainer for vee-belt pulley, No. 143400).Fig. 9-14 The screw securing the vee-belt pulley has a left-hand thread.

9-153. Disassemble the nut on the fuel-injection pump's driving shaft. (Use the universal device No. 110340 or a 19 mm socket spanner).Fig. 9-15 Important:As from 1975, the hub was modified in the case of rigid drive. (The thread for attachment of tool No. 110340 with sleeve has been omitted). Remove gear-wheel fastening screws. (See Section 7)

9-164. Mount the tool without sleeve if the pump drive has on injection timer. If it has no injection timer mount the tool with sleeve (Universal device No. 110340).Fig. 9-16

9-175. Pull the injection pump drive from the pump shaft. Dismantle the pump and the securing flange.Fig. 9-17

9-186. Dismantle the injectors, upper cover plate, valve covers and rocker arm shaft brackets, remove the push-rods and unscrew the plugs. (Use socket spanner No. 120040, square socket insert No. 120060)Fig. 9-18, left7. Slacken the cylinder head studs in stages, in diagonal sequence. (Use socket spanner No. 120040)Fig. 9-18, right8. Dismantle the cylinder heads and pushrod sheaths.

9-199. Turn engine upside down. Dismantle the sump with sheet-metal partition, crankcase breather and oil strainer. Disassemble the big-end bearing bolts. (Use bent socket spanner No. 131540)Fig. 9-1910. Slacken and remove the big-end bearing caps. Withdraw the cylinders with pistons and connecting rods from the crankcase. Remove the halves of bearing shells and mark them on the back corresponding to the connecting rods with an electric scriber. Make sure that the bearing shells do not get damaged.11. Dismantle the oil pump and idler gear, camshaft and tappets, flywheel and main bearing caps.12. Remove the crankshaft and the halves of bearing shells. Mark the bearing shells on the back corresponding to the crankcase with an electric scriber. Unscrew the plugs, oil feeders and oil injection nozzles from the crankcase. Clean all parts and thouroughly wash out the oilways.

9-20 Remove horizontal oil nozzles. Fig. 9-2013. Check all parts for suitability for reuse.Assembling The Crankshaft Assembly (as from 3 cylinder engine)

It is assumed that the liner is fitted in the front camshaft bearing bore.

9-611. Place the crankcase with the cylinder head joint face downwards. Screw the dosing plugs in the oilways of

9-13 Immediately fuel line unions are dismantled plug or fit caps on the connecting stubs and pipe ends.Fig. 9-13

9-142. Dismantle the vee-belt pulley for the air compressor, main belt pulley and front cover. (Use retainer for vee-belt pulley, No. 143400).Fig. 9-14 The screw securing the vee-belt pulley has a left-hand thread.

9-153. Disassemble the nut on the fuel-injection pump's driving shaft. (Use the universal device No. 110340 or a 19 mm socket spanner).Fig. 9-15 Important:As from 1975, the hub was modified in the case of rigid drive. (The thread for attachment of tool No. 110340 with sleeve has been omitted). Remove gear-wheel fastening screws. (See Section 7)

9-164. Mount the tool without sleeve if the pump drive has on injection timer. If it has no injection timer mount the tool with sleeve (Universal device No. 110340).Fig. 9-16

9-175. Pull the injection pump drive from the pump shaft. Dismantle the pump and the securing flange.Fig. 9-17

9-186. Dismantle the injectors, upper cover plate, valve covers and rocker arm shaft brackets, remove the push-rods and unscrew the plugs. (Use socket spanner No. 120040, square socket insert No. 120060)Fig. 9-18, left7. Slacken the cylinder head studs in stages, in diagonal sequence. (Use socket spanner No. 120040)Fig. 9-18, right8. Dismantle the cylinder heads and pushrod sheaths.

9-199. Turn engine upside down. Dismantle the sump with sheet-metal partition, crankcase breather and oil strainer. Disassemble the big-end bearing bolts. (Use bent socket spanner No. 131540)Fig. 9-1910. Slacken and remove the big-end bearing caps. Withdraw the cylinders with pistons and connecting rods from the crankcase. Remove the halves of bearing shells and mark them on the back corresponding to the connecting rods with an electric scriber. Make sure that the bearing shells do not get damaged.11. Dismantle the oil pump and idler gear, camshaft and tappets, flywheel and main bearing caps.12. Remove the crankshaft and the halves of bearing shells. Mark the bearing shells on the back corresponding to the crankcase with an electric scriber. Unscrew the plugs, oil feeders and oil injection nozzles from the crankcase. Clean all parts and thouroughly wash out the oilways.

9-20 Remove horizontal oil nozzles. Fig. 9-2013. Check all parts for suitability for reuse.Assembling The Crankshaft Assembly (as from 3 cylinder engine)

It is assumed that the liner is fitted in the front camshaft bearing bore.

9-611. Place the crankcase with the cylinder head joint face downwards. Screw the dosing plugs in the oilways of