Rating:

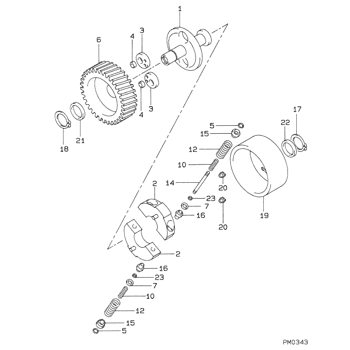

Information washer, plate, sk Denso

Include in ##:

09180-03241

as WASHER, PLATE, SK

Cross reference number

Part num

Firm num

Firm

Name

94901-39030

ME736090

WASHER, PLATE, SK

9490139030

22885-8940A

HINO

WASHER, PLATE, SK

9490139030

ME736090

MITSUBISHI

WASHER, PLATE, SK

9490139030

90099-01592

TOYOTA

WASHER, PLATE, SK

Information:

The information that is provided is the latest recommendations for Caterpillar diesel engines that are covered by this Special Publication. This information supersedes all previous recommendations which have been published for Caterpillar diesel engines that are covered by this Special Publication. Special fluids are required for some engines and it will be necessary to continue to use these special products. Refer to the applicable Operation and Maintenance Manual.This publication is a supplement to the Operation and Maintenance Manual. This publication does not replace the engine specific Operation and Maintenance Manuals.

These recommendations are subject to change without notice. Consult your local Caterpillar dealer for the most up to date recommendations.

Many of the guidelines, recommendations, and requirements that are provided in this Special Publication are interrelated. Before using the provided information, it is the responsibility of the user of this Special Publication to read and understand the information provided in its entirety.It is the responsibility of the user of this Special Publication to follow all safety guidelines found in this Special Publication and in engine and/or machine specific Operation and Maintenance Manual when performing all recommended and/or required engine, engine systems, and/or machine maintenance.For questions concerning the information presented in this Special Publication and/or in your product Operation and Maintenance Manual, and/or for additional guidelines and recommendations (including maintenance interval recommendations/requirements) consult your Caterpillar dealer.

Commercial products that make generic claims of meeting "Cat" and/or "Caterpillar" requirements without listing the specific Cat recommendations and/or requirements that are met may not provide acceptable performance and may cause reduced engine and/or machine fluid compartment life. Refer to this Special Publication and refer to product specific Operation and Maintenance Manual for Caterpillar fluids recommendations and/or requirements.

Note: Instructions for the installation of the filter are printed on the side of each Caterpillar spin-on filter. For non-Caterpillar filters, refer to the installation instructions that are provided by the supplier of the filter.

In order to meet expected fuel system component life, 4 micron(c) absolute or less secondary fuel filtration is required for all Caterpillar diesel engines that are equipped with common-rail fuel systems, and for all Caterpillar diesel engines that are equipped with unit injected fuel systems. For all other Caterpillar diesel engines (mostly older engines with pump, line and nozzle type fuel systems), the use of 4 micron(c) absolute or less secondary fuel filtration is strongly recommended. Note that all current Caterpillar diesel engines are factory equipped with Caterpillar Advanced Efficiency 4 micron(c) absolute fuel filters.In order to obtain additional information on Caterpillar designed and produced filtration products, refer to the "Reference Material" article, "Filters" and "Miscellaneous" topics in this Special Publication, and then consult your Caterpillar dealer for assistance with filtration recommendations for your Caterpillar machine.

Faulty engine coolant temperature regulators, or operating with light loads, short operation cycles, excessive idling, or operating in applications where normal operating temperature is seldom reached can contribute to excessive water in the crankcase oil. Corrosive damage, piston deposits, increased oil consumption, and other damage can result. If a complete

These recommendations are subject to change without notice. Consult your local Caterpillar dealer for the most up to date recommendations.

Many of the guidelines, recommendations, and requirements that are provided in this Special Publication are interrelated. Before using the provided information, it is the responsibility of the user of this Special Publication to read and understand the information provided in its entirety.It is the responsibility of the user of this Special Publication to follow all safety guidelines found in this Special Publication and in engine and/or machine specific Operation and Maintenance Manual when performing all recommended and/or required engine, engine systems, and/or machine maintenance.For questions concerning the information presented in this Special Publication and/or in your product Operation and Maintenance Manual, and/or for additional guidelines and recommendations (including maintenance interval recommendations/requirements) consult your Caterpillar dealer.

Commercial products that make generic claims of meeting "Cat" and/or "Caterpillar" requirements without listing the specific Cat recommendations and/or requirements that are met may not provide acceptable performance and may cause reduced engine and/or machine fluid compartment life. Refer to this Special Publication and refer to product specific Operation and Maintenance Manual for Caterpillar fluids recommendations and/or requirements.

Note: Instructions for the installation of the filter are printed on the side of each Caterpillar spin-on filter. For non-Caterpillar filters, refer to the installation instructions that are provided by the supplier of the filter.

In order to meet expected fuel system component life, 4 micron(c) absolute or less secondary fuel filtration is required for all Caterpillar diesel engines that are equipped with common-rail fuel systems, and for all Caterpillar diesel engines that are equipped with unit injected fuel systems. For all other Caterpillar diesel engines (mostly older engines with pump, line and nozzle type fuel systems), the use of 4 micron(c) absolute or less secondary fuel filtration is strongly recommended. Note that all current Caterpillar diesel engines are factory equipped with Caterpillar Advanced Efficiency 4 micron(c) absolute fuel filters.In order to obtain additional information on Caterpillar designed and produced filtration products, refer to the "Reference Material" article, "Filters" and "Miscellaneous" topics in this Special Publication, and then consult your Caterpillar dealer for assistance with filtration recommendations for your Caterpillar machine.

Faulty engine coolant temperature regulators, or operating with light loads, short operation cycles, excessive idling, or operating in applications where normal operating temperature is seldom reached can contribute to excessive water in the crankcase oil. Corrosive damage, piston deposits, increased oil consumption, and other damage can result. If a complete