Rating:

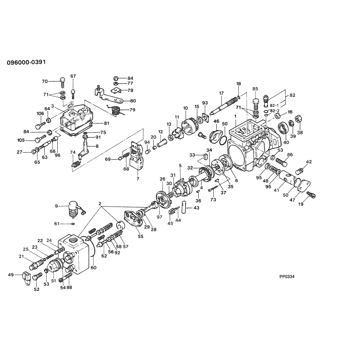

Information washer, governor g Denso

Include in ##:

09600-00390

as WASHER, GOVERNOR G

Cross reference number

Part num

Firm num

Firm

Name

09626-60170

WASHER, GOVERNOR G

0962660170

8-97141320-0

ISUZU

WASHER, GOVERNOR G

0962660170

ME736410

MITSUBISHI

WASHER, GOVERNOR G

0962660170

ME736412

MITSUBISHI

WASHER, GOVERNOR G

0962660170

RF10 24 129

MAZDA

WASHER, GOVERNOR G

Information:

Never operate without proper temperature thermostats in the cooling system. The thermostats maintain the engine coolant at the proper operating temperature.Never add coolant or water to an overheated engine, engine damage can result. Allow the engine to cool first. Filling at over 5 U.S. gallon (20 L) per minute can cause air pockets in the cooling system.Caterpillar does not recommend the use of cooling system solutions that are intended to stop leaks. Use of these products may result in engine damage.Caterpillar recommends that the coolant mixture contain a minimum of 30 percent Caterpillar Antifreeze, or equivalent to prevent water pump cavitation on engines with air-to-air aftercooling.The cooling system should be protected with a minimum of three percent concentration of liquid supplemental coolant additive at all times, regardless of the concentration of antifreeze.If the engine is to be stored in, or shipped to, an area with freezing temperatures, the cooling system must be protected to the lowest expected outside (ambient temperature.

Check the specific gravity of the antifreeze solution frequently in cold weather to ensure adequate freeze protection.Coolant Mixture for Caterpillar Engines

Proper engine coolant is a combination of water, antifreeze and supplemental coolant additive. Each ingredient of the mixture must meet specific guidelines for the engine coolant to perform properly. The coolant mixture used in Caterpillar engines must provide the following functions.* Adequate heat transfer.* Cavitation erosion protection.* Freeze & boil protection.* Sludge & scale protection.* Corrosion protection.* Compatibility with system hoses & seals.Water (Coolant)

Water is corrosive at engine operating temperature. Distilled or deionized water is recommended because of less mineral drop out than hard or tap water. Tap water, even artificially softened with salt, is not recommended for use in your engine's cooling system.Calcium, magnesium, chlorides and sulfates are all minerals that make up the dissolved solids in the water. Excessive amounts of these minerals (in hard water) can combine with supplemental coolant additives (silicates and phosphates) to form sludge or scale deposits. The mineral deposits (silicates, phosphates, calcium and magnesium) reduce the effectiveness of the cooling system, especially after a number of heating and cooling cycles. They may collect on hot internal engine surfaces and in the cooling system to reduce the effectiveness of the cooling system.If distilled or de-ionized water is NOT available, use water that meets the minimum acceptable requirements in the chart. To determine your water characteristics, contact the local water department, agricultural agent or an independent laboratory to perform the testing service. Antifreeze

Some applications have elected to run with supplemental coolant additive treated water without glycol. Do not mix coolant additive treated water in the cooling system with Caterpillar Antifreeze. This incompatibility could cause cooling system damage because the coolant will have an excessive concentration of coolant additive. Follow the instructions provided by the antifreeze supplier.

Caterpillar recommends that the coolant mixture contain a minimum of 30 percent Caterpillar Antifreeze (or equivalent) with 70 percent distilled or deionized water to maintain an adequate cavitation temperature for efficient water pump performance. Antifreeze concentration should be selected