Rating:

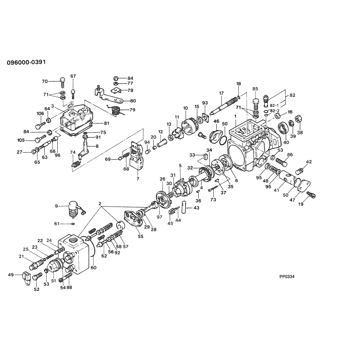

Information washer, flyweight Denso

Include in ##:

09600-00390

as WASHER, FLYWEIGHT

Cross reference number

Part num

Firm num

Firm

Name

09626-50030

22753-5402

WASHER, FLYWEIGHT

0962650030

22753-54020

TOYOTA

WASHER, FLYWEIGHT

0962650030

22753-54020

TOYOTA

WASHER, FLYWEIGHT

0962650030

8-97140828-0

ISUZU

WASHER, FLYWEIGHT

0962650030

ME736319

MITSUBISHI

WASHER, FLYWEIGHT

0962650030

S501 24 233

MAZDA

WASHER, FLYWEIGHT

Information:

Zinc Rods

Zinc rods are inserted in the engine's raw water cooling system to help prevent the corrosive action of salt (sea) water. The reaction of the zinc to the sea (raw) water causes the rods to deteriorate, instead of more critical engine cooling system parts.Therefore, the zinc rods must be inspected every 50 service hours, and replaced when they have deteriorated.Depending on the engine and attachments, their location may be in the oil cooler heat exchanger bonnet, raw water heat exchanger bonnet, aftercooler lines, raw water pump and/or in the raw water lines.Inspect

Removing Old Zinc Rods

1. Remove and observe condition of all zinc rods. They are painted red for easy identification. 2. Tap the zinc rods lightly with a hammer. If a rod has deteriorated, or flakes apart when tapped, install a new zinc rod.Installing New Zinc Rods

1. Unscrew or drill the existing rod from the plug base.2. Apply 9S3263 Thread Lock to the internal threads of the plug(s) holding the zinc rod(s). Install new rod(s) in the plug base(s).3. Coat the external pipe threads with 5P3413 Pipe Sealant and install the plug(s) into their proper locations in the raw water system.Marine Gear

Drain Oil and Replace Filter

With the oil warm and the engine stopped, drain the oil and replace oil filter element on a new or rebuilt marine gear at the first 50 Hour interval to ensure draining of possible large debris and particles from the oil and gear housing.Drain and change filter element with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. Suspended waste particles will settle on the bottom and will not be removed with the draining oil if the oil is cold.Failure to follow this recommended procedure would result in these waste particles being recirculated through your marine gear system with the new oil. Refer to the topic in the Every 1000 Hour maintenance interval in this manual for instructions and procedure.For lubrication and maintenance requirements for your marine gear model, refer to the OEM and/or vessel manufacturer's recommendations.Marine Gear Operation, Maintenance, Warranty & Parts Support

Caterpillar encourages customers to refer to their Caterpillar dealer and/or marine gear OEM dealer for information regarding operation and maintenance for the transmission.All warranty and parts support for the marine gear (including installation and service problem resolution) will be the responsibility of the selling dealer and the marine gear OEM.Air Tank

Drain Water and Sediment

When required, or at least on a weekly basis, open the drain valve on the air tank and drain the water and sediment. Close the valve.

Zinc rods are inserted in the engine's raw water cooling system to help prevent the corrosive action of salt (sea) water. The reaction of the zinc to the sea (raw) water causes the rods to deteriorate, instead of more critical engine cooling system parts.Therefore, the zinc rods must be inspected every 50 service hours, and replaced when they have deteriorated.Depending on the engine and attachments, their location may be in the oil cooler heat exchanger bonnet, raw water heat exchanger bonnet, aftercooler lines, raw water pump and/or in the raw water lines.Inspect

Removing Old Zinc Rods

1. Remove and observe condition of all zinc rods. They are painted red for easy identification. 2. Tap the zinc rods lightly with a hammer. If a rod has deteriorated, or flakes apart when tapped, install a new zinc rod.Installing New Zinc Rods

1. Unscrew or drill the existing rod from the plug base.2. Apply 9S3263 Thread Lock to the internal threads of the plug(s) holding the zinc rod(s). Install new rod(s) in the plug base(s).3. Coat the external pipe threads with 5P3413 Pipe Sealant and install the plug(s) into their proper locations in the raw water system.Marine Gear

Drain Oil and Replace Filter

With the oil warm and the engine stopped, drain the oil and replace oil filter element on a new or rebuilt marine gear at the first 50 Hour interval to ensure draining of possible large debris and particles from the oil and gear housing.Drain and change filter element with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. Suspended waste particles will settle on the bottom and will not be removed with the draining oil if the oil is cold.Failure to follow this recommended procedure would result in these waste particles being recirculated through your marine gear system with the new oil. Refer to the topic in the Every 1000 Hour maintenance interval in this manual for instructions and procedure.For lubrication and maintenance requirements for your marine gear model, refer to the OEM and/or vessel manufacturer's recommendations.Marine Gear Operation, Maintenance, Warranty & Parts Support

Caterpillar encourages customers to refer to their Caterpillar dealer and/or marine gear OEM dealer for information regarding operation and maintenance for the transmission.All warranty and parts support for the marine gear (including installation and service problem resolution) will be the responsibility of the selling dealer and the marine gear OEM.Air Tank

Drain Water and Sediment

When required, or at least on a weekly basis, open the drain valve on the air tank and drain the water and sediment. Close the valve.