Rating:

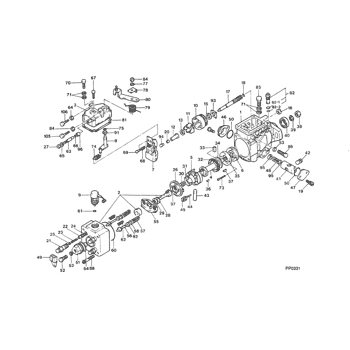

Information washer, timer sens Denso

Include in ##:

09600-00431

as WASHER, TIMER SENS

Cross reference number

Part num

Firm num

Firm

Name

09621-40050

22625-5427

WASHER, TIMER SENS

0962140050

22625-54272

TOYOTA

WASHER, TIMER SENS

0962140050

22625-54272

TOYOTA

WASHER, TIMER SENS

0962140050

8-97141353-0

ISUZU

WASHER, TIMER SENS

0962140050

4782 13 TE2

MAZDA

WASHER, TIMER SENS

Information:

Fuel Ratio Control

Inspect/Check

Inspect the fuel ratio control diaphragm for any sign of leaking. Check for any cracking or deterioration of the diaphragm.Slow engine response and low power may indicate a need for adjustment or repair. This adjustment should not be attempted by untrained personnel. Your Caterpillar dealer is equipped with the necessary tools, personnel and procedures to perform this service.Governor Set Point And Low Idle

Check/Adjust

The only on-engine adjustment to the governor is the low idle setting. All other governor adjustments are to be made during bench (off engine) testing. Refer to the Special Instruction SEHS8868 for procedures and tooling required for bench testing the governor.

These adjustments are to be made only by an authorized Caterpillar dealer or mechanic that has the correct training. A governor set point that is incorrectly adjusted could result in excessive fuel consumption.

Your Caterpillar dealer has all of the necessary equipment to check and adjust your governor. The Low Idle screw is normally set during the bench test procedure. However, if the low idle setting is not satisfactory, use 1U6672 Wrench to loosen the locknut and adjust screw to the desired low idle speed. Tighten the locknut and recheck the low idle setting. Refer to the Fuel Setting And Related Information Fiche for the correct low idle speed for your engine. This information can be obtained from your Caterpillar dealer.Top End Overhaul

According to the Maintenance Management Schedule, it's time to have your engine overhauled. However, with the exception of burning a little oil and experiencing a slight increase in fuel consumption, you are not having any other problems with your truck.The choice to continue running or to overhaul the engine is yours. But remember, component failures are inevitable. Maybe there won't be a failure in the immediate future, but there will be a failure at some point in time. The figures shown in the following scenario are based on certain assumptions for the purpose of presenting an example only.Your truck has 525,000 miles (845 250 km) on its 3406B Engine. If the truck runs for 75,000 more miles (120 750 km) and then fails, the repair cost will be between U.S. $0.0085 and $0.0153 per mile (km). However, if you choose to repair your engine before it fails, by performing an in-frame overhaul at a cost of U.S. $3700, the repair cost will only be U.S. $0.007 cents per mile (km). The difference between the repair before failure cost and the after failure cost is the result of damage to other engine parts when a major failure occurs. This is money that is not only wasted, but is money that could have been used more profitably elsewhere.By not performing an overhaul, you risk the chance of seizing a piston, breaking a rod, fatiguing a bearing or causing other severe damage to your engine. The cost to repair this damage could range from U.S. $5000 to $9000 and the amount of downtime encountered would exceed the amount of downtime required for a scheduled in-frame overhaul.Consider

Inspect/Check

Inspect the fuel ratio control diaphragm for any sign of leaking. Check for any cracking or deterioration of the diaphragm.Slow engine response and low power may indicate a need for adjustment or repair. This adjustment should not be attempted by untrained personnel. Your Caterpillar dealer is equipped with the necessary tools, personnel and procedures to perform this service.Governor Set Point And Low Idle

Check/Adjust

The only on-engine adjustment to the governor is the low idle setting. All other governor adjustments are to be made during bench (off engine) testing. Refer to the Special Instruction SEHS8868 for procedures and tooling required for bench testing the governor.

These adjustments are to be made only by an authorized Caterpillar dealer or mechanic that has the correct training. A governor set point that is incorrectly adjusted could result in excessive fuel consumption.

Your Caterpillar dealer has all of the necessary equipment to check and adjust your governor. The Low Idle screw is normally set during the bench test procedure. However, if the low idle setting is not satisfactory, use 1U6672 Wrench to loosen the locknut and adjust screw to the desired low idle speed. Tighten the locknut and recheck the low idle setting. Refer to the Fuel Setting And Related Information Fiche for the correct low idle speed for your engine. This information can be obtained from your Caterpillar dealer.Top End Overhaul

According to the Maintenance Management Schedule, it's time to have your engine overhauled. However, with the exception of burning a little oil and experiencing a slight increase in fuel consumption, you are not having any other problems with your truck.The choice to continue running or to overhaul the engine is yours. But remember, component failures are inevitable. Maybe there won't be a failure in the immediate future, but there will be a failure at some point in time. The figures shown in the following scenario are based on certain assumptions for the purpose of presenting an example only.Your truck has 525,000 miles (845 250 km) on its 3406B Engine. If the truck runs for 75,000 more miles (120 750 km) and then fails, the repair cost will be between U.S. $0.0085 and $0.0153 per mile (km). However, if you choose to repair your engine before it fails, by performing an in-frame overhaul at a cost of U.S. $3700, the repair cost will only be U.S. $0.007 cents per mile (km). The difference between the repair before failure cost and the after failure cost is the result of damage to other engine parts when a major failure occurs. This is money that is not only wasted, but is money that could have been used more profitably elsewhere.By not performing an overhaul, you risk the chance of seizing a piston, breaking a rod, fatiguing a bearing or causing other severe damage to your engine. The cost to repair this damage could range from U.S. $5000 to $9000 and the amount of downtime encountered would exceed the amount of downtime required for a scheduled in-frame overhaul.Consider