Rating:

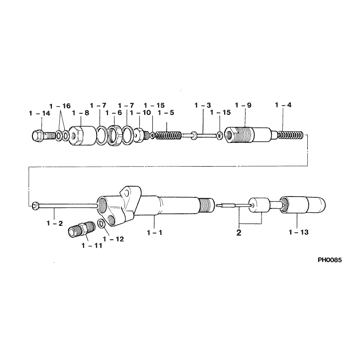

Information washer Denso

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09317-53860

WASHER

0931753860

ME703883

MITSUBISHI

WASHER

Information:

Engine Operation

* Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load.* To get the vehicle in motion, use a gear that will result in a smooth, easy start to move the load without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Interrupted slipping and abrupt clutch engagement put stress on the drive train and waste fuel.* Use progressive shifting to reduce fuel consumption. Progressive shifting is using only the rpm required to make an upshift into the next gear. The amount of rpm required to make an upshift increases as the vehicle/truck speed increases unless upshifts are made on upgrades. Experience with your vehicle/truck will show you how much rpm is required to make upshifts under various conditions.* If the vehicle/truck can be operated in a higher gear after the desired speed is reached, select the highest gear available that will pull the load. By following this recommendation, you will lower your fuel costs. Your engine will be operating at the lowest rpm required to pull the load.Fuel Economy

Fuel is the largest single operating cost of today's on-highway truck engines. Improved fuel economy can have a substantial impact on operating profit. The most significant factors that influence vehicle fuel economy are:* Driver techniques* Vehicle efficiency/Truck Specifications* Operating conditions* Engine efficiencyDriver Techniques

The manner in which a vehicle is driven can have a dramatic effect on fuel consumption. Operators can maximize fuel economy and engine life by practicing the techniques of using minimum power and low engine rpm. The following tips can optimize fuel economy by making maximum use of the potential efficiency of the engine and vehicle.Caterpillar engines are designed to operate at lower engine rpm (speed) and have demonstrated excellent fuel savings and longer service life when operated in this manner.Uphill Operation

Minimize the number of downshifts. Vehicle speed (momentum) is always lost between downshifts. Therefore, unnecessary downshifts waste a portion of that fuel consumed to maintain vehicle speed in the previous gear. Your Caterpillar engine has a very broad usable speed range and excellent torque rise that will provide exceptional hill climbing capability.For best performance when climbing a hill, allow the engine to lug down to peak torque (1560 rpm) speed before downshifting and allow the engine run at a lower speed (down to 1400 rpm) if the truck/vehicle will make the top without another downshift. Fuel economy will be best if you let the engine lug back to around this speed before you downshift. Downshift until a gear is reached in which the engine will pull the load. This technique will also operate the engine through the most fuel efficient speed range.Allowing the engine to lug below peak torque is permissible if the truck/vehicle is cresting the top of a hill without downshifting. However, note that extended operation in a lug condition will raise exhaust temperature and cylinder pressure. This can lead

* Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load.* To get the vehicle in motion, use a gear that will result in a smooth, easy start to move the load without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Interrupted slipping and abrupt clutch engagement put stress on the drive train and waste fuel.* Use progressive shifting to reduce fuel consumption. Progressive shifting is using only the rpm required to make an upshift into the next gear. The amount of rpm required to make an upshift increases as the vehicle/truck speed increases unless upshifts are made on upgrades. Experience with your vehicle/truck will show you how much rpm is required to make upshifts under various conditions.* If the vehicle/truck can be operated in a higher gear after the desired speed is reached, select the highest gear available that will pull the load. By following this recommendation, you will lower your fuel costs. Your engine will be operating at the lowest rpm required to pull the load.Fuel Economy

Fuel is the largest single operating cost of today's on-highway truck engines. Improved fuel economy can have a substantial impact on operating profit. The most significant factors that influence vehicle fuel economy are:* Driver techniques* Vehicle efficiency/Truck Specifications* Operating conditions* Engine efficiencyDriver Techniques

The manner in which a vehicle is driven can have a dramatic effect on fuel consumption. Operators can maximize fuel economy and engine life by practicing the techniques of using minimum power and low engine rpm. The following tips can optimize fuel economy by making maximum use of the potential efficiency of the engine and vehicle.Caterpillar engines are designed to operate at lower engine rpm (speed) and have demonstrated excellent fuel savings and longer service life when operated in this manner.Uphill Operation

Minimize the number of downshifts. Vehicle speed (momentum) is always lost between downshifts. Therefore, unnecessary downshifts waste a portion of that fuel consumed to maintain vehicle speed in the previous gear. Your Caterpillar engine has a very broad usable speed range and excellent torque rise that will provide exceptional hill climbing capability.For best performance when climbing a hill, allow the engine to lug down to peak torque (1560 rpm) speed before downshifting and allow the engine run at a lower speed (down to 1400 rpm) if the truck/vehicle will make the top without another downshift. Fuel economy will be best if you let the engine lug back to around this speed before you downshift. Downshift until a gear is reached in which the engine will pull the load. This technique will also operate the engine through the most fuel efficient speed range.Allowing the engine to lug below peak torque is permissible if the truck/vehicle is cresting the top of a hill without downshifting. However, note that extended operation in a lug condition will raise exhaust temperature and cylinder pressure. This can lead