Rating:

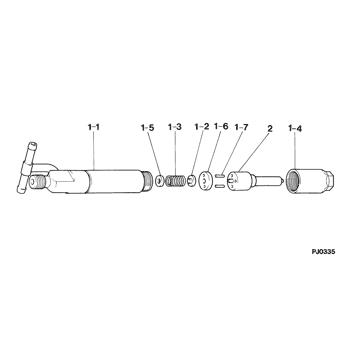

Information washer Denso

Include in ##:

09350-02390

as WASHER

Cross reference number

Part num

Firm num

Firm

Name

09317-52210

WASHER

0931752210

ME703215

MITSUBISHI

WASHER

0931752210

MM514348

MITSUBISHI

WASHER

Information:

Daily

Walk-Around Inspection - Inspect for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner Indicator - Test Air Starting Motor (If Equipped) - Check/fill oiler bowlEvery 18 950 L (5000 gal) of Fuel or 125 Hours*

Scheduled Oil Sampling (S O S) Analysis - Obtain sample Engine Oil & Filters - Change oil and oil filter(s) Fuel System - Drain water/sediment Cooling System - Test Crankcase Breathers - Clean Engine Valve Lash (At First Oil Change Only) - Check/AdjustEvery 37 900 L (10,000 gal) of Fuel or 250 Hours*

Batteries - Clean/Check electrolyte level Belts, Hoses and Clamps - Inspect/Replace if necessary Engine Air Cleaners - Replace Engine Speed Sensors - Inspect/clean magnetic pick-upEvery 151 600 L (40,000 gal) of Fuel or 1000 Hours*

Engine Protection Devices - Inspect for proper operation (Check at least twice per year) Engine Valve Lash - Check/Adjust Turbochargers - Inspect for proper operation Engine Mounts and Crankshaft Vibration Damper - Inspect/checkEvery 341 100 L (90,000 gal) of Fuel or 2250 Hours*

Connecting Rod Bearings - ReplaceEvery 454 800 L (120,000 gal) of Fuel or 3000 Hours or Two Years*

Cooling System - Clean/Flush/replace thermostats and gasketsOverhaul Every 511 650 L (135,000 gal) of Fuel or 5400 Hours*

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Refer to the Overhaul section in this manual on page 85. Top End Overhaul After Failure Overhaul Starting Motor - Inspect for proper operation Alternator - Inspect for proper operation Engine Speed Sensors - Inspect/clean/test*First Perform Previous Service Hour Items Caterpillar suggests that fuel consumption be used as the preferred method of determining maintenance intervals. Fuel consumption/hours will vary depending on the proper application of your engine rating and adherence to recommended maintenance procedures.

Walk-Around Inspection - Inspect for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner Indicator - Test Air Starting Motor (If Equipped) - Check/fill oiler bowlEvery 18 950 L (5000 gal) of Fuel or 125 Hours*

Scheduled Oil Sampling (S O S) Analysis - Obtain sample Engine Oil & Filters - Change oil and oil filter(s) Fuel System - Drain water/sediment Cooling System - Test Crankcase Breathers - Clean Engine Valve Lash (At First Oil Change Only) - Check/AdjustEvery 37 900 L (10,000 gal) of Fuel or 250 Hours*

Batteries - Clean/Check electrolyte level Belts, Hoses and Clamps - Inspect/Replace if necessary Engine Air Cleaners - Replace Engine Speed Sensors - Inspect/clean magnetic pick-upEvery 151 600 L (40,000 gal) of Fuel or 1000 Hours*

Engine Protection Devices - Inspect for proper operation (Check at least twice per year) Engine Valve Lash - Check/Adjust Turbochargers - Inspect for proper operation Engine Mounts and Crankshaft Vibration Damper - Inspect/checkEvery 341 100 L (90,000 gal) of Fuel or 2250 Hours*

Connecting Rod Bearings - ReplaceEvery 454 800 L (120,000 gal) of Fuel or 3000 Hours or Two Years*

Cooling System - Clean/Flush/replace thermostats and gasketsOverhaul Every 511 650 L (135,000 gal) of Fuel or 5400 Hours*

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Refer to the Overhaul section in this manual on page 85. Top End Overhaul After Failure Overhaul Starting Motor - Inspect for proper operation Alternator - Inspect for proper operation Engine Speed Sensors - Inspect/clean/test*First Perform Previous Service Hour Items Caterpillar suggests that fuel consumption be used as the preferred method of determining maintenance intervals. Fuel consumption/hours will vary depending on the proper application of your engine rating and adherence to recommended maintenance procedures.