Rating:

Information washer Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$1.38

12 Sep 2024

0.01[0.00] Pounds

Amazon.com

Hacus - Forklift FPE241774 Washer for Nozzle 15Z Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Include in ##:

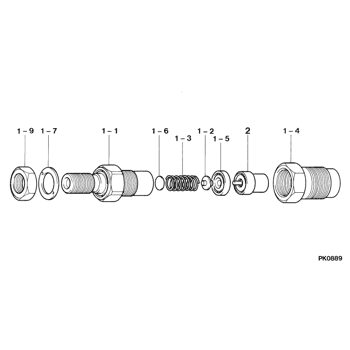

09350-02240

as WASHER

Cross reference number

Part num

Firm num

Firm

Name

09317-51690

WASHER

0931751690

ME736857

MITSUBISHI

WASHER

Information:

Caterpillar Diesel Engines are capable of burning a wide range of distillate fuels. The use of clean, stable blends of distillate fuel which meet the following requirements will provide quality engine service life. Filterability

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems. Refer to topic, Cold Weather Operation, for additional information.Sulfur

The percentage of sulfur in the fuel will affect the engine oil recommendations. Fuel sulfur is chemically changed during combustion to form both sulfurous and sulfuric acid. These acids chemically attack metal surfaces and cause corrosive wear.Certain additives used in lubricating oils contain alkaline compounds that are formulated to neutralize these acids. The measure of this reserve alkalinity in a lubricating oil is known as its Total Base Number (TBN). TBN values are essential to neutralize the acids from combustion gases and to minimize corrosive wear.Fuels containing 0.5% total weight or LESS sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils. With sulfur ABOVE the 0.5% level, use API CF-4 performance oils with an ASTM D2896 Total Base Number (TBN) of 10 times the fuel sulfur for DI engines and 20 times for PC engines for normal oil drain intervals. ASTM Specs can normally be found at your local technological society, library or college.Caterpillar recommends infrared analysis (in conjunction with wear metal analysis) of used oil in determining the effectiveness of oil TBN and acid neutralization. The Caterpillar dealer S O S program provides this information. Regular oil analysis (S O S) will provide information to monitor oil properties and engine wear metals to maintain successful engine protection and establish oil drain intervals.Periodically request fuel sulfur content information from your fuel supplier. Fuel sulfur content can change with each bulk delivery. American Petroleum Institute (API) classification performance oils should have sufficient TBN for fuels with less than 0.5% sulfur. Fuels containing 0.5% or less sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils.Additives

Fuel additives are generally not recommended nor needed for the specified fuels listed. Cetane improvers can be used as necessary for the direct injection engine requirements. Biocides may be needed to eliminate microorganism growth in storage tanks. In cold conditions, treatment for entrained water may also be necessary.Consult your fuel supplier about the use of additives to prevent incompatibility among additives already in the fuel and the additives to be used. Other fuel types may be used when economics or fuel availability dictate. Consult your Caterpillar dealer for more information and advice on any specific fuel.For more information on fuel selection and fuel properties, refer to Diesel Fuels and Your Engine, SEBD0717 or contact your Caterpillar dealer.

Clean fuels should have no more than 0.1% of sediment and water. Storage of fuel for extended periods of time can cause fuel oxidation with solids forming, causing filtering problems. Refer to topic, Cold Weather Operation, for additional information.Sulfur

The percentage of sulfur in the fuel will affect the engine oil recommendations. Fuel sulfur is chemically changed during combustion to form both sulfurous and sulfuric acid. These acids chemically attack metal surfaces and cause corrosive wear.Certain additives used in lubricating oils contain alkaline compounds that are formulated to neutralize these acids. The measure of this reserve alkalinity in a lubricating oil is known as its Total Base Number (TBN). TBN values are essential to neutralize the acids from combustion gases and to minimize corrosive wear.Fuels containing 0.5% total weight or LESS sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils. With sulfur ABOVE the 0.5% level, use API CF-4 performance oils with an ASTM D2896 Total Base Number (TBN) of 10 times the fuel sulfur for DI engines and 20 times for PC engines for normal oil drain intervals. ASTM Specs can normally be found at your local technological society, library or college.Caterpillar recommends infrared analysis (in conjunction with wear metal analysis) of used oil in determining the effectiveness of oil TBN and acid neutralization. The Caterpillar dealer S O S program provides this information. Regular oil analysis (S O S) will provide information to monitor oil properties and engine wear metals to maintain successful engine protection and establish oil drain intervals.Periodically request fuel sulfur content information from your fuel supplier. Fuel sulfur content can change with each bulk delivery. American Petroleum Institute (API) classification performance oils should have sufficient TBN for fuels with less than 0.5% sulfur. Fuels containing 0.5% or less sulfur may be used with recommended crankcase oil drain intervals using API CF-4 performance oils.Additives

Fuel additives are generally not recommended nor needed for the specified fuels listed. Cetane improvers can be used as necessary for the direct injection engine requirements. Biocides may be needed to eliminate microorganism growth in storage tanks. In cold conditions, treatment for entrained water may also be necessary.Consult your fuel supplier about the use of additives to prevent incompatibility among additives already in the fuel and the additives to be used. Other fuel types may be used when economics or fuel availability dictate. Consult your Caterpillar dealer for more information and advice on any specific fuel.For more information on fuel selection and fuel properties, refer to Diesel Fuels and Your Engine, SEBD0717 or contact your Caterpillar dealer.