Rating:

Information valve sub-assy, ti Denso

Include in ##:

09800-00010

as VALVE SUB-ASSY, TI

Cross reference number

Part num

Firm num

Firm

Name

09821-00010

VALVE SUB-ASSY, TI

Information:

Fuel System Inspection

1. Look at the reading on the gauge for fuel pressure. Not enough fuel pressure is an indication of a problem with the components that send fuel to the engine.2. Check the fuel level in the fuel tank. Look at the cap for the fuel tank to make sure the vent is not filled with dirt.3. Check the fuel lines for fuel leakage. Be sure the fuel supply line does not have a restriction or a bad bend.4. Install a new fuel filter. Clean the primary fuel filter if so equipped.5. Remove any dirt that may be in the fuel system.6. Check fuel flow from orifice check valve. Flow should be about 8 oz. in 25 seconds (250 ml in 22 seconds) with the pressure in the housing for the fuel injection pumps at 30 5 psi (205 35 kPa).Testing Fuel Injection Equipment

An easy check can be made to find the cylinder that is misfiring, or running rough, and causing black smoke to come out of the exhaust pipe.Run the engine at the speed that gives misfiring. Loosen the fuel line nut at a fuel injection pump. This will stop the flow of fuel to that cylinder. Do this for each cylinder until a loosened fuel line is found that makes no difference in engine misfiring. Be sure to tighten each fuel line nut after the test before the next fuel line nut is loosened. Check each cylinder by this method. When a cylinder is found where the loosened fuel line nut does not make a difference in engine running, test the injection pump and injection valve for that cylinder.Fuel Injection Lines

Fuel from the fuel injection pumps is sent through the fuel injection lines to the fuel injection valves.Each fuel injection line of an engine has a special design and must be installed in a certain location. When fuel injection lines are removed from an engine, put identification marks or tags on the fuel lines as they are removed, so they can be put in the correct location when they are installed.

TIGHTENING THE NUT OF A FUEL INJECTION LINE

1. 5P144 Fuel Line Socket.The nuts that hold a fuel injection line to an injection valve and injection pump must be kept tight. Use a torque wrench and the 5P144 Fuel Line Socket (1) to tighten the fuel line nuts to 30 5 lb. ft. (40 7 N m).Injection Pumps

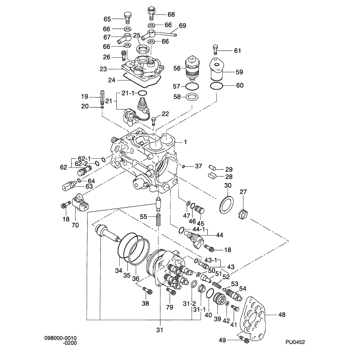

When injection pumps, sleeves and lifters are removed from the injection pump housing, keep the parts of each pump together so they can be installed back in their original location.Be careful when disassembling injection pumps. Do not damage the surface on the plunger. The plunger, sleeve and barrel for each pump are made as a set. Do not put the plunger of one pump in the barrel or sleeve of another pump. If one part is worn, install a complete new pump assembly. Be careful when putting the plunger in the bore of the barrel

1. Look at the reading on the gauge for fuel pressure. Not enough fuel pressure is an indication of a problem with the components that send fuel to the engine.2. Check the fuel level in the fuel tank. Look at the cap for the fuel tank to make sure the vent is not filled with dirt.3. Check the fuel lines for fuel leakage. Be sure the fuel supply line does not have a restriction or a bad bend.4. Install a new fuel filter. Clean the primary fuel filter if so equipped.5. Remove any dirt that may be in the fuel system.6. Check fuel flow from orifice check valve. Flow should be about 8 oz. in 25 seconds (250 ml in 22 seconds) with the pressure in the housing for the fuel injection pumps at 30 5 psi (205 35 kPa).Testing Fuel Injection Equipment

An easy check can be made to find the cylinder that is misfiring, or running rough, and causing black smoke to come out of the exhaust pipe.Run the engine at the speed that gives misfiring. Loosen the fuel line nut at a fuel injection pump. This will stop the flow of fuel to that cylinder. Do this for each cylinder until a loosened fuel line is found that makes no difference in engine misfiring. Be sure to tighten each fuel line nut after the test before the next fuel line nut is loosened. Check each cylinder by this method. When a cylinder is found where the loosened fuel line nut does not make a difference in engine running, test the injection pump and injection valve for that cylinder.Fuel Injection Lines

Fuel from the fuel injection pumps is sent through the fuel injection lines to the fuel injection valves.Each fuel injection line of an engine has a special design and must be installed in a certain location. When fuel injection lines are removed from an engine, put identification marks or tags on the fuel lines as they are removed, so they can be put in the correct location when they are installed.

TIGHTENING THE NUT OF A FUEL INJECTION LINE

1. 5P144 Fuel Line Socket.The nuts that hold a fuel injection line to an injection valve and injection pump must be kept tight. Use a torque wrench and the 5P144 Fuel Line Socket (1) to tighten the fuel line nuts to 30 5 lb. ft. (40 7 N m).Injection Pumps

When injection pumps, sleeves and lifters are removed from the injection pump housing, keep the parts of each pump together so they can be installed back in their original location.Be careful when disassembling injection pumps. Do not damage the surface on the plunger. The plunger, sleeve and barrel for each pump are made as a set. Do not put the plunger of one pump in the barrel or sleeve of another pump. If one part is worn, install a complete new pump assembly. Be careful when putting the plunger in the bore of the barrel