Rating:

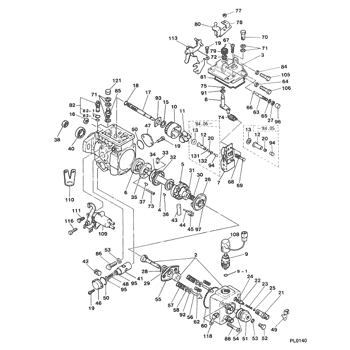

Information valve sub-assy, di Denso

Include in ##:

09600-00830

as VALVE SUB-ASSY, DI

Cross reference number

Part num

Firm num

Firm

Name

09642-00510

22104-6A29

VALVE SUB-ASSY, DI

0964200510

22104-6A290

TOYOTA

VALVE SUB-ASSY, DI

0964200510

22148-54010

TOYOTA

VALVE SUB-ASSY, DI

0964200510

22104-6A290

TOYOTA

VALVE SUB-ASSY, DI

0964200510

8-97161867-0

ISUZU

VALVE SUB-ASSY, DI

0964200510

4782 13 V21B

MAZDA

VALVE SUB-ASSY, DI

0964200510

ME736327

MITSUBISHI

VALVE SUB-ASSY, DI

Information:

Most marine transmissions can be back driven (propeller wind milling with dead engine) under the following conditions, provided that vessel speed does not exceed normal maximum propulsion speed of the vessel. For intermittent back driving, such as:* Sailboat auxiliary (short trips)* Towing purse boats in seining operations1. Start the engine and operate the marine gear in neutral, at normal oil pressure, for a minimum of five minutes. Do this once every 24 hours.2. Maintain the marine transmission oil level the same for back driving as for normal propulsion, or keep level above FULL mark on dipstick.3. Make sure the marine transmission is in neutral while the craft is being towed. For continuous back driving, such as:* Sailboat auxiliary (long trips)* Towing to deliver a boat* Towing home a boat with engine trouble (long trip-more than a day)1. Operate in neutral with oil at normal oil pressure for a minimum of five minutes every 12 hours.2. Fill the marine gear with oil until the oil level touches the input shaft on the engine centerline.3. Make sure the marine transmission is in neutral while the craft is being towed.Securing the Propeller

Reverse wind milling can cause engine damage. The best way to prevent reverse wind milling is to secure the propeller. If possible, lock the propeller shaft to prevent rotation.After the propeller shaft has been secured, have the towing vessel travel at slow speed in order to minimize the wind milling force on the propeller. If the vessel is being towed and the marine transmission is allowed to windmill for long periods, the engine must be started and the marine transmission operated for five minutes every 12 hours to lubricate the propeller shaft bearings.There are several ways of preventing propeller shaft rotation. The correct method depends upon the turning force of the propeller, and the construction of the propeller shaft tunnel. Use the method best suited for the type of installation.Propeller Shaft Wrapping

1. On small vessels, wrap a heavy rope around the propeller shaft. The number of wraps needed will depend upon the mass of the propeller and propeller shaft.2. Secure the rope in the opposite direction of propeller shaft rotation.Securing the Companion Flange

1. Remove one or more bolts from the companion flange coupling. Bolt a chain to the companion flange. Wrap the chain several times around the propeller shaft.2. Secure the loose end of the chain at a right angle to the propeller shaft and in the opposite direction of propeller shaft rotation.

Reverse wind milling can cause engine damage. The best way to prevent reverse wind milling is to secure the propeller. If possible, lock the propeller shaft to prevent rotation.After the propeller shaft has been secured, have the towing vessel travel at slow speed in order to minimize the wind milling force on the propeller. If the vessel is being towed and the marine transmission is allowed to windmill for long periods, the engine must be started and the marine transmission operated for five minutes every 12 hours to lubricate the propeller shaft bearings.There are several ways of preventing propeller shaft rotation. The correct method depends upon the turning force of the propeller, and the construction of the propeller shaft tunnel. Use the method best suited for the type of installation.Propeller Shaft Wrapping

1. On small vessels, wrap a heavy rope around the propeller shaft. The number of wraps needed will depend upon the mass of the propeller and propeller shaft.2. Secure the rope in the opposite direction of propeller shaft rotation.Securing the Companion Flange

1. Remove one or more bolts from the companion flange coupling. Bolt a chain to the companion flange. Wrap the chain several times around the propeller shaft.2. Secure the loose end of the chain at a right angle to the propeller shaft and in the opposite direction of propeller shaft rotation.