Rating:

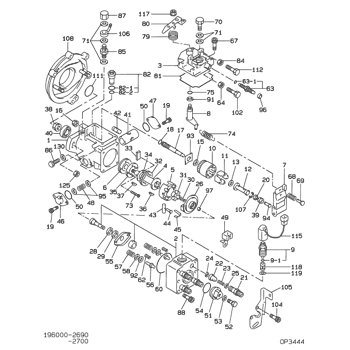

Information spring, timer, out Denso

Include in ##:

19600-02690

as SPRING, TIMER, OUT

Cross reference number

Part num

Firm num

Firm

Name

09620-82510

SPRING, TIMER, OUT

Information:

1. Defective Upper O-ring On Unit Injectors Or Leaking Unit Injector Using the fuel priming pump, pressurize the fuel system to 689 kPa (100 psi). Check for fuel on the top deck of the cylinder head (a small amount of leakage is normal from the injector plunger barrel area after 5 minutes of constant pressure). If fuel is found, drain the fuel supply manifold. Remove each unit injector (see 3176 Vehicular Diesel Engine Disassembly and Assembly, Form No. SENR4965), and check for a defective upper O-ring on the unit injector or if the unit injector itself is leaking.A bad injector to sleeve seat causes combustion gas leakage that can damage the injector O-rings. Inspect injector hold down bolt thread depth for a minimum of 25 mm (.984 in) of thread depth in the cylinder head.Testing of the injectors must be done off of the engine. Use the 1U6661 Pop (Injector) Tester Group with a 1U6663 Injector Holding Block, and a 1U6665 Power Supply, to test the injectors. For the test procedure refer to Special Instruction, Form No. SEHS8867, Using The 1U6661 Pop (Injector) Tester. For test specifications refer to Special Instruction, Form No. SEHS8804, Unit Injector Test Specifications for 1.7 Liter Engines. Inspect and repair as necessary the sealing surface (seat) of the injector sleeve in the cylinder head when removing and installing an injector. The injector sealing surface (seat) must be free of scratches or evidence of combustion products. If it is necessary to rework (ream) or replace the sleeve use 4C4054 Tool Group and refer to Special Instruction, Form No. SEHS9246, Using The 4C4054 Unit Injector Sleeve Replacement Tool Group.2. Injector Not Seated Properly A bad injector to sleeve seat causes combustion gas leakage that can damage the injector o-rings. Inspect injector hold down bolt thread depth for a minimum of 25 mm (.984 in) of thread depth in the cylinder head.Torque fuel injector hold down bolt to 33 7 N m (24 5 lb ft). Inspect and repair as necessary the sealing surface (seat) of the injector sleeve in the cylinder head when removing and installing an injector. The injector sealing surface (seat) must be free of scratches or evidence of combustion products. If it is necessary to rework (ream) or replace the sleeve use 4C4054 Tool Group and refer to Special Instruction, Form No. SEHS9246, Using The 4C4054 Unit Injector Sleeve Replacement Tool Group.3. Crack(s) In Cylinder Head Pressurize the fuel gallery and check for crack(s). Crack(s) between the cylinder head fuel passages and passages open to the crankcase will allow fuel to enter the crankcase.4. Porosity In Cylinder HeadPressurize the fuel gallery and check for porosity. Leakage may be due to the proximity of the hole to internal fuel passages.