Rating:

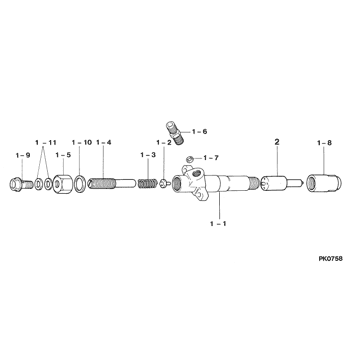

Information spring, nozzle hol Denso

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09312-70470

SPRING, NOZZLE HOL

Information:

Introduction

The 240-0716 Tube Kit is available for repair of the high pressure oil line. The kit is used in order to replace the flexible high pressure oil line. The oil line is part of the Hydraulic Electronic Unit Injector (HEUI) Pump.The 240-0716 Tube Kit is used on engine models with the following serial number prefixes: 1AJ, 6PZ and 7JZ.

Table 1

Components in 240-0716 Tube Kit

Callout Part Number Description Quantity

11 9M-1974 Washer 1

13 122-5855 Spacer 1

10 8S-8820 Clip 1

12 8C-5748 Bolt 1

9 6V-8636 Connector 1

17 6V-9001 Elbow 1

15 214-7568 O-ring 2

16 221-3494 O-ring 2

14 241-3782 Tube assembly 1

18 033-6028 O-ring 1

19 123-3132 Backup ring 1

20 033-6039 O-ring 1 Removal of the Flexible Oil Line

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Remove any coolant lines that may interfere with the installation. Remove any air inlet lines that may interfere with the installation.

Illustration 1 g01006397

Typical example (1) Bolt (2) Washer (3) Air inlet cover

Remove bolt (1) and the washer (2) from the air inlet cover (3). Discard the bolt (1) and the washer (2) .

Disconnect the electrical connector of the injection actuation pressure control valve (7). Remove the injection actuation pressure control valve (7) from the pump. Retain the injection actuation pressure control valve (7) for the reinstallation.Note: Modifications to the tools may need to be made in order to reduce interference with engine components.

Illustration 2 g01007381

Modified 2P-5494 crowfoot wrench

Remove the hose assembly (5), the connector (8), and the elbow (6). Discard these parts.

Illustration 3 g01006381

(4) HEUI pump (5) Flexible oil line (6) Elbow (7) Injection actuation pressure control valve (8) ConnectorInstallation of the 240-0716 Tube Kit

Illustration 4 g01006407

(4) HEUI pump (7) Injection actuation pressure control valve (9) Connector (10) Clip (11) Washer (12) Bolt (13) Spacer (14) Tube assembly (15) O-ring (16) O-ring (17) Elbow

Illustration 5 g01006437

(7) Injection actuation pressure control valve (9) Connector (15) O-ring (16) O-ring (17) Elbow

Apply a light coat of oil to the O-rings (15) and (16) during installation. Install the O-ring (15) on the connector (9). Install the O-ring (16) on the connector (9). Thread the connector (9) into the port on

The 240-0716 Tube Kit is available for repair of the high pressure oil line. The kit is used in order to replace the flexible high pressure oil line. The oil line is part of the Hydraulic Electronic Unit Injector (HEUI) Pump.The 240-0716 Tube Kit is used on engine models with the following serial number prefixes: 1AJ, 6PZ and 7JZ.

Table 1

Components in 240-0716 Tube Kit

Callout Part Number Description Quantity

11 9M-1974 Washer 1

13 122-5855 Spacer 1

10 8S-8820 Clip 1

12 8C-5748 Bolt 1

9 6V-8636 Connector 1

17 6V-9001 Elbow 1

15 214-7568 O-ring 2

16 221-3494 O-ring 2

14 241-3782 Tube assembly 1

18 033-6028 O-ring 1

19 123-3132 Backup ring 1

20 033-6039 O-ring 1 Removal of the Flexible Oil Line

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Remove any coolant lines that may interfere with the installation. Remove any air inlet lines that may interfere with the installation.

Illustration 1 g01006397

Typical example (1) Bolt (2) Washer (3) Air inlet cover

Remove bolt (1) and the washer (2) from the air inlet cover (3). Discard the bolt (1) and the washer (2) .

Disconnect the electrical connector of the injection actuation pressure control valve (7). Remove the injection actuation pressure control valve (7) from the pump. Retain the injection actuation pressure control valve (7) for the reinstallation.Note: Modifications to the tools may need to be made in order to reduce interference with engine components.

Illustration 2 g01007381

Modified 2P-5494 crowfoot wrench

Remove the hose assembly (5), the connector (8), and the elbow (6). Discard these parts.

Illustration 3 g01006381

(4) HEUI pump (5) Flexible oil line (6) Elbow (7) Injection actuation pressure control valve (8) ConnectorInstallation of the 240-0716 Tube Kit

Illustration 4 g01006407

(4) HEUI pump (7) Injection actuation pressure control valve (9) Connector (10) Clip (11) Washer (12) Bolt (13) Spacer (14) Tube assembly (15) O-ring (16) O-ring (17) Elbow

Illustration 5 g01006437

(7) Injection actuation pressure control valve (9) Connector (15) O-ring (16) O-ring (17) Elbow

Apply a light coat of oil to the O-rings (15) and (16) during installation. Install the O-ring (15) on the connector (9). Install the O-ring (16) on the connector (9). Thread the connector (9) into the port on