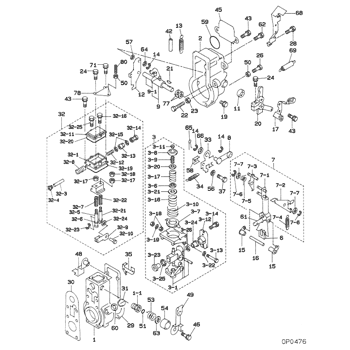

Rating:

Information spring, idling Denso

Include in ##:

09130-00513

as SPRING, IDLING

Cross reference number

Part num

Firm num

Firm

Name

09138-90570

SPRING, IDLING

0913890570

22411-1660

HINO

SPRING, IDLING

0913890570

22411-1660A

HINO

SPRING, IDLING

0913890570

22768-78031

TOYOTA

SPRING, IDLING

0913890570

ME703120

MITSUBISHI

SPRING, IDLING

0913890570

S2241-11660-A

HINO

SPRING, IDLING

Information:

Table 2

Specifications for Valve Opening Pressure

Nozzle Assembly Valve Opening Pressure

1W-5829

10300 to 17690 kPa (1500 to 2505 psi)

4W-1819

4W-8483

7E-3969

7N-0449

7W-3710

7W-8043

9N-3979

101-0060

115-3354

122-9007

9L-7883

16560 to 17990 kPa (2400 to 2600 psi)

9L-9263

9N-2366

9L-6969

13090 to 19900 kPa (1900 2900 psi)

9N-3299

9N-3700 If the fuel nozzle is not within specifications, stop the test and do not use the nozzle.Check for Tip Leakage

Close the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi) gauge).

Flush the fuel nozzle that is being tested by pumping the tester for 3 full strokes.

Open the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi) gauge).

Use a clean cloth to dry the tip and the body of the fuel injector. All test fluid should be wiped from the nozzle assembly.

A clean cloth should be wrapped around the top of the fuel nozzle in order to absorb any internal return leakage.

Calculate the test pressure that will be used for the tip leakage test.Use the fuel nozzle's valve opening pressure, that has been previously recorded, in order to calculate the test pressure for the nozzle that is being tested.

Subtract a value of 1875 kPa (275 psi) from the valve opening pressure that was previously obtained.

Record the result of the calculation as the test pressure that will be used for the tip leakage test.

Slowly apply the test pressure, that has been calculated in Step 6, to the fuel nozzle.

Close the pump isolator valve.

Hold this test pressure for 10 seconds.

Count the number of drops of test fluid that drips from the nozzle during the duration of the test. Open the pump isolator valve in order to release the pressure on the fuel nozzle when the test is completed.Refer to the information that is provided in Table 3 in order to evaluate the results of the test.Note: Ensure that any test fluid that collects on the tip of the fuel nozzle is not fluid leakage from the test fixture.

Table 3

Specifications for Tip Leakage

(Leakage within 15 seconds after the test pressure is applied to the nozzle.)

Nozzle Assembly Maximum Leakage

1W-5829 20 drops (1)

4W-1819

4W-8483

7E-3969

7N-0449

7W-3710

7W-8043

9N-3979

101-0060

115-3354

122-9007

9L-7883 3 drops (1)

9L-9263

9N-2366

9L-6969 30 drops (1)

9N-3299

9N-3700

( 1 ) No minimum specificationIf the tip leakage for the fuel nozzle is not within specifications, stop the test and do not use the fuel nozzle.Test the Fuel Nozzle for Plugged Orifices

Illustration 2 g00923165

Spray patterns for pencil type fuel nozzles.

Close the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi) gauge).

Rapidly increase the pressure on the fuel nozzle until fluid sprays from the tip of the fuel nozzle.Note: For this test, each full