Rating:

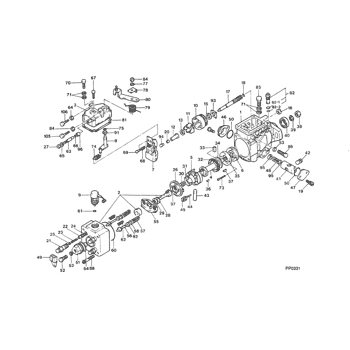

Information solenoid assy, fue Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

12V Fuel Cut-Off Stop Solenoid Compatible With And Engine Models 0960300070 0960100690 0960300160

YUthNX Discover the reliability of the 12V Pump Fuel Cut-Off Stop Solenoid, compatible with and engines. || Experience effortless installation with models including 096030-0070, 096010-0690, and 096030-0160. || Ensure engine with automatic fuel cut-off to prevent leaks and ensure performance. || Benefit from a robust design tailored Compatible With a wide range of and vehicles. || Enjoy consistent performance during various driving conditions, enhancing overall vehicle functionality. || Utilize a temperature-resistant solenoid that maintains effective in varying climates. || Count on dependable compatibility, making it an essential component Compatible With your vehicle maintenance needs.

YUthNX Discover the reliability of the 12V Pump Fuel Cut-Off Stop Solenoid, compatible with and engines. || Experience effortless installation with models including 096030-0070, 096010-0690, and 096030-0160. || Ensure engine with automatic fuel cut-off to prevent leaks and ensure performance. || Benefit from a robust design tailored Compatible With a wide range of and vehicles. || Enjoy consistent performance during various driving conditions, enhancing overall vehicle functionality. || Utilize a temperature-resistant solenoid that maintains effective in varying climates. || Count on dependable compatibility, making it an essential component Compatible With your vehicle maintenance needs.

1pcs 096030-0080 096030-0160 09610-0690

KCNOPXAEB

KCNOPXAEB

You can buy:

Include in ##:

09600-00431

as SOLENOID ASSY, FUE

Cross reference number

Part num

Firm num

Firm

Name

09603-00160

22390-6A51

SOLENOID ASSY, FUE

0960300160

22390-6A510

TOYOTA

SOLENOID ASSY, FUE

0960300160

22390-6A510

TOYOTA

SOLENOID ASSY, FUE

0960300160

8-97140781-0

ISUZU

SOLENOID ASSY, FUE

0960300160

ME736821

MITSUBISHI

SOLENOID ASSY, FUE

Information:

Scheduled Oil Sampling (S O S)

Refer to the information in the Scheduled Oil Sampling section in this publication regarding the description and specifications for acceptable sampling.Obtain Sample

To compliment a good preventive maintenance program, Caterpillar recommends using S O S at regular scheduled intervals to monitor the condition of your engine and engine oil to help determine the maintenance requirements of your engine.Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase. There are several methods used to obtain S O S samples from Caterpillar diesel engines.* Use a sampling gun inserted into the sump.* Use a valve installed for samples.* Use the drain stream method when changing oil.Caterpillar recommends the first two methods. However, if these methods are not possible, then use a drain stream method when changing the oil.If the drain stream method is used to obtain the oil sample, take the sample after some oil has drained and before the final drain oil stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of circulating oil in the compartment and may carry debris that can give false S O S analysis results.Refer to How to Take a Good Oil Sample, PEHP6001 for a step-by-step explanation if using this method of sampling oil.Contact your Caterpillar dealer for information and assistance in establishing the S O S program for your engine and application.Oil Drain Intervals

It is essential that an S O S analysis be performed to analyze oil condition before oil change period adjustment is considered. If the engine crankcase oil has reached its condemning limits as established by the oil analysis program, refer to the topic, Engine Oil and Filter(s), in this publication for the procedure to change the crankcase oil and oil filters.Due to manufacturing tolerances, engine application and maintenance variation, all engines do not consume fuel and oil at the same rate. Some history of fuel and oil consumed for each engine (or group of engines) in a similar application must be established.For a group of engines, determine the average fuel consumption and add oil rate. This is performed by multiplying the total quantity of fuel consumed by the operating (service) hours of the engines.For more information on adjusting oil change intervals for specific applications, see your Caterpillar dealer.Engine Oil and Filters

Refer to the Lubricant Viscosity and Refill Capacities charts in this publication for the recommended type and amount of oil to use for this engine.Drain Oil

Stop the engine. Refer to the Engine Stopping procedure in this publication.

Drain the crankcase with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. Failure to follow this recommended procedure would result in these waste particles being recirculated through your engine lubrication system with the new oil. While draining the oil, obtain a sample for oil analysis. * Remove the

Refer to the information in the Scheduled Oil Sampling section in this publication regarding the description and specifications for acceptable sampling.Obtain Sample

To compliment a good preventive maintenance program, Caterpillar recommends using S O S at regular scheduled intervals to monitor the condition of your engine and engine oil to help determine the maintenance requirements of your engine.Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase. There are several methods used to obtain S O S samples from Caterpillar diesel engines.* Use a sampling gun inserted into the sump.* Use a valve installed for samples.* Use the drain stream method when changing oil.Caterpillar recommends the first two methods. However, if these methods are not possible, then use a drain stream method when changing the oil.If the drain stream method is used to obtain the oil sample, take the sample after some oil has drained and before the final drain oil stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of circulating oil in the compartment and may carry debris that can give false S O S analysis results.Refer to How to Take a Good Oil Sample, PEHP6001 for a step-by-step explanation if using this method of sampling oil.Contact your Caterpillar dealer for information and assistance in establishing the S O S program for your engine and application.Oil Drain Intervals

It is essential that an S O S analysis be performed to analyze oil condition before oil change period adjustment is considered. If the engine crankcase oil has reached its condemning limits as established by the oil analysis program, refer to the topic, Engine Oil and Filter(s), in this publication for the procedure to change the crankcase oil and oil filters.Due to manufacturing tolerances, engine application and maintenance variation, all engines do not consume fuel and oil at the same rate. Some history of fuel and oil consumed for each engine (or group of engines) in a similar application must be established.For a group of engines, determine the average fuel consumption and add oil rate. This is performed by multiplying the total quantity of fuel consumed by the operating (service) hours of the engines.For more information on adjusting oil change intervals for specific applications, see your Caterpillar dealer.Engine Oil and Filters

Refer to the Lubricant Viscosity and Refill Capacities charts in this publication for the recommended type and amount of oil to use for this engine.Drain Oil

Stop the engine. Refer to the Engine Stopping procedure in this publication.

Drain the crankcase with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. Failure to follow this recommended procedure would result in these waste particles being recirculated through your engine lubrication system with the new oil. While draining the oil, obtain a sample for oil analysis. * Remove the