Rating:

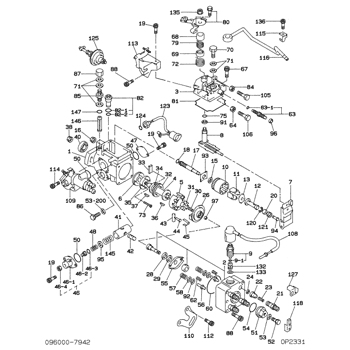

Information sleeve, governor Denso

Include in ##:

09600-07942

as SLEEVE, GOVERNOR

Cross reference number

Part num

Firm num

Firm

Name

09625-21530

22316-6D39

SLEEVE, GOVERNOR

0962521530

22316-6D390

TOYOTA

SLEEVE, GOVERNOR

0962521530

ME736826

MITSUBISHI

SLEEVE, GOVERNOR

Information:

Parts Needed

Engine Removal

Disconnect the cables to the batteries to prevent the possibility of personal injury and/or damage to electrical or electronic equipment. Refer to Service Manual for the engine removal information. The engine and torque converter may be removed as a unit if adequate lifting facilities exist.Approximate unit weights: Engine: 4364 kg (9600 lb). Torque converter: 567 kg (1,250 lb).It is not necessary to discharge refrigerant from the air-conditioning system when changing engines. Remove the condenser core and lines from the radiator guard and engine as a unit. Move core and lines to one side during the engine removal and reinstallation process. Engine mounted pumps may also be removed with hoses intact to minimize fluid loss and possible system contamination.Certain engine accessories may be reused if the accessories are serviceable. The condition of accessories should be evaluated prior to reinstalling them on the machine. Pay attention to the condition and cleanliness of any items being reused. Failure to replace unserviceable parts or adequately clean parts being reused will reduce the service life of the engine being installed. For reuse and inspection guidelines refer to Special Instruction, SEHS9634. Major items which may be reused if serviceable are:* Air inlet piping* Air cleaners (with new filter elements)* Exhaust piping* Starters* Fuel lines to engine* Special attachments installed on the engine* RadiatorInspect the frame and mounting locations for the engine supports and repair as necessary.Engine Installation

Before installing the engine, attach any component which may be difficult to attach later, such as the starter motors. Air cleaners and sensors for indicating air cleaner restriction, the sender for the coolant gauge, and engine mounted components of the starting aid system may also be installed at this time. (See the following topics and the wiring schematic for installation details and correct electrical connections.)If adequate facilities exist, install the engine and torque converter as an assembly into the machine's frame. Tighten engine support bolts to the specified torque. Reassemble radiator and guard, and reattach coolant and fuel lines. Install hydraulic pumps, lines, and other items such as drive shafts and guards which were removed earlier. Exhaust piping, hood and other engine attachments may also be reinstalled. (Do not reconnect the batteries at this time.)Engine Accessories and Engine Wiring

If you are installing a new or remanufactured engine from Caterpillar (with rear mounted alternator) the engine wiring harness will match the requirements of both the EUI engine and machine systems. Most electrical system connections to engine mounted devices will have already been made. Other connections must be made to both engine accessory and machine systems to ensure proper machine operation. When converting a machine from an MUI to EUI engine, it may be necessary to change wire terminal ends or connectors to adapt to another harness or device. If it is necessary to convert from one type of connector to another, use the correct size connector components and proper tools. Also ensure that wires are properly oriented within the connector. See the Reference Literature list for instructions

Engine Removal

Disconnect the cables to the batteries to prevent the possibility of personal injury and/or damage to electrical or electronic equipment. Refer to Service Manual for the engine removal information. The engine and torque converter may be removed as a unit if adequate lifting facilities exist.Approximate unit weights: Engine: 4364 kg (9600 lb). Torque converter: 567 kg (1,250 lb).It is not necessary to discharge refrigerant from the air-conditioning system when changing engines. Remove the condenser core and lines from the radiator guard and engine as a unit. Move core and lines to one side during the engine removal and reinstallation process. Engine mounted pumps may also be removed with hoses intact to minimize fluid loss and possible system contamination.Certain engine accessories may be reused if the accessories are serviceable. The condition of accessories should be evaluated prior to reinstalling them on the machine. Pay attention to the condition and cleanliness of any items being reused. Failure to replace unserviceable parts or adequately clean parts being reused will reduce the service life of the engine being installed. For reuse and inspection guidelines refer to Special Instruction, SEHS9634. Major items which may be reused if serviceable are:* Air inlet piping* Air cleaners (with new filter elements)* Exhaust piping* Starters* Fuel lines to engine* Special attachments installed on the engine* RadiatorInspect the frame and mounting locations for the engine supports and repair as necessary.Engine Installation

Before installing the engine, attach any component which may be difficult to attach later, such as the starter motors. Air cleaners and sensors for indicating air cleaner restriction, the sender for the coolant gauge, and engine mounted components of the starting aid system may also be installed at this time. (See the following topics and the wiring schematic for installation details and correct electrical connections.)If adequate facilities exist, install the engine and torque converter as an assembly into the machine's frame. Tighten engine support bolts to the specified torque. Reassemble radiator and guard, and reattach coolant and fuel lines. Install hydraulic pumps, lines, and other items such as drive shafts and guards which were removed earlier. Exhaust piping, hood and other engine attachments may also be reinstalled. (Do not reconnect the batteries at this time.)Engine Accessories and Engine Wiring

If you are installing a new or remanufactured engine from Caterpillar (with rear mounted alternator) the engine wiring harness will match the requirements of both the EUI engine and machine systems. Most electrical system connections to engine mounted devices will have already been made. Other connections must be made to both engine accessory and machine systems to ensure proper machine operation. When converting a machine from an MUI to EUI engine, it may be necessary to change wire terminal ends or connectors to adapt to another harness or device. If it is necessary to convert from one type of connector to another, use the correct size connector components and proper tools. Also ensure that wires are properly oriented within the connector. See the Reference Literature list for instructions