Rating:

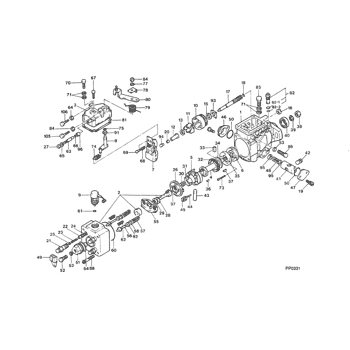

Information sleeve, governor Denso

Include in ##:

09600-00431

as SLEEVE, GOVERNOR

Cross reference number

Part num

Firm num

Firm

Name

09625-20250

22316-5411

SLEEVE, GOVERNOR

0962520250

22316-54112

TOYOTA

SLEEVE, GOVERNOR

Information:

Alarms

The alarm systems provide a signal to the operator that an abnormal operating condition exists. Abnormal operating conditions can include:* High engine jacket water temperature* Low engine oil pressure* Low cooling system coolant levelThe alarm will continue until the cause of the condition is corrected. The engine can be damaged if no corrective action is taken when an alarm is activated. To prevent this from occurring to unattended engines, engine shutoff devices are also used.Shutoff and Alarm System Testing

Refer to the Service Manual for the testing procedure.Check all engine protective devices according to the Maintenance Schedule. All engine protective devices must be checked and maintained to provide the engine with proper protection if a component malfunction or failure should occur.Your Caterpillar dealer has the trained personnel and equipment to perform this maintenance.Emergency Engine Stop

Always determine the cause of the engine shutdown. Make necessary repairs before attempting restarting the engine.

The engine may be equipped with Emergency Stop controls. Emergency Stop controls are for EMERGENCY use ONLY. DO NOT use Emergency shutoff devices or controls for normal stopping procedure. Refer to the Engine Stopping section of this manual for normal stopping procedures.Familiarize yourself with the locations of the shutoff controls. Emergency shutoff controls should only be used when an emergency exists, and not used to routinely stop the engine.Engine Protection Shutdowns

Engine protection shutdowns are electronically operated. Their function is to stop the engine for such reasons as loss of speed signal and power loss to the ECM.Temperature warnings can be wired to relays by the customer to affect automatic shutdown. Leads are available in the wiring harness for customer supplied inlet air shutdown valves.Engine Coolant Temperature

Engine coolant temperature sensor location.The engine coolant temperature sensor monitors engine coolant temperature and performs high engine coolant temperature annunciation (and diagnostics for the Electronic engines).This feature is used for engine system diagnostics. The output from the ECM can be used to drive a relay or a lamp to annunciate high coolant temperature condition. In addition, it enables and activates the cold start strategy, and improves engine startability.High Coolant Temperature Alarm (if equipped)

The sensing element must be submerged in the coolant to operate properly. Ensure your cooling system is at the proper level.

The switch is located on the right rear of the cylinder block for 3408 engines and on the right rear of the cylinder block for 3412 engines. Excessive water temperature closes the switch. Maximum coolant temperature to trip alarm is 104°C (219°F). The switch opens as the coolant cools. No resetting procedure is required.Coolant Temperature Sensor Failure

When the sensor output is open, shorted to ground or supply, or measured coolant temperature reading is out of specification, a sensor failure may have occurred.The ECM will detect the coolant temperature sensor failure and through the diagnostic lamp warn the user of a coolant temperature sensor failure. The coolant temperature sensor related strategies will be disabled. The coolant temperature sensor failure will not cause an engine shut down, power derating, or any speed change.Low Coolant Level

The

The alarm systems provide a signal to the operator that an abnormal operating condition exists. Abnormal operating conditions can include:* High engine jacket water temperature* Low engine oil pressure* Low cooling system coolant levelThe alarm will continue until the cause of the condition is corrected. The engine can be damaged if no corrective action is taken when an alarm is activated. To prevent this from occurring to unattended engines, engine shutoff devices are also used.Shutoff and Alarm System Testing

Refer to the Service Manual for the testing procedure.Check all engine protective devices according to the Maintenance Schedule. All engine protective devices must be checked and maintained to provide the engine with proper protection if a component malfunction or failure should occur.Your Caterpillar dealer has the trained personnel and equipment to perform this maintenance.Emergency Engine Stop

Always determine the cause of the engine shutdown. Make necessary repairs before attempting restarting the engine.

The engine may be equipped with Emergency Stop controls. Emergency Stop controls are for EMERGENCY use ONLY. DO NOT use Emergency shutoff devices or controls for normal stopping procedure. Refer to the Engine Stopping section of this manual for normal stopping procedures.Familiarize yourself with the locations of the shutoff controls. Emergency shutoff controls should only be used when an emergency exists, and not used to routinely stop the engine.Engine Protection Shutdowns

Engine protection shutdowns are electronically operated. Their function is to stop the engine for such reasons as loss of speed signal and power loss to the ECM.Temperature warnings can be wired to relays by the customer to affect automatic shutdown. Leads are available in the wiring harness for customer supplied inlet air shutdown valves.Engine Coolant Temperature

Engine coolant temperature sensor location.The engine coolant temperature sensor monitors engine coolant temperature and performs high engine coolant temperature annunciation (and diagnostics for the Electronic engines).This feature is used for engine system diagnostics. The output from the ECM can be used to drive a relay or a lamp to annunciate high coolant temperature condition. In addition, it enables and activates the cold start strategy, and improves engine startability.High Coolant Temperature Alarm (if equipped)

The sensing element must be submerged in the coolant to operate properly. Ensure your cooling system is at the proper level.

The switch is located on the right rear of the cylinder block for 3408 engines and on the right rear of the cylinder block for 3412 engines. Excessive water temperature closes the switch. Maximum coolant temperature to trip alarm is 104°C (219°F). The switch opens as the coolant cools. No resetting procedure is required.Coolant Temperature Sensor Failure

When the sensor output is open, shorted to ground or supply, or measured coolant temperature reading is out of specification, a sensor failure may have occurred.The ECM will detect the coolant temperature sensor failure and through the diagnostic lamp warn the user of a coolant temperature sensor failure. The coolant temperature sensor related strategies will be disabled. The coolant temperature sensor failure will not cause an engine shut down, power derating, or any speed change.Low Coolant Level

The