Rating:

Information shim, lift adjusti Denso

Include in ##:

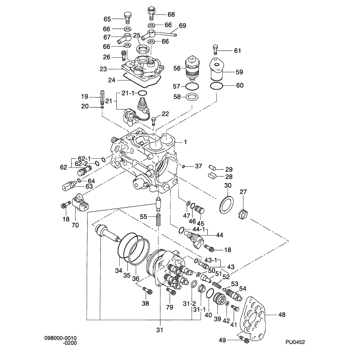

09800-00010

as SHIM, LIFT ADJUSTI

Cross reference number

Part num

Firm num

Firm

Name

09838-30720

SHIM, LIFT ADJUSTI

Information:

3. Disconnect tube assembly (1) and hose assembly (4) from the engine. Disconnect hose assemblies (2) and (3) from the air compressor. 4. Remove the three bolts (6), the nuts and lockwashers that hold air compressor (5) to the flywheel housing. Remove the air compressor and gasket from the flywheel housing.Install Air Compressor

1. Put air compressor (1) and the gasket in position on the flywheel housing. Install the three bolts, lockwashers and nuts to hold it. 2. Connect hose assemblies (2) and (5) to the air compressor. Connect hose assembly (4) and tube assembly (3) to the engine.3. Fill the cooling system with coolant to the correct level.Disassemble Air Compressor

start by:a) remove air compressorb) remove accessory drive1. Remove the water line elbow, the air line elbows and oil (drain) tube from the air compressor. 2. Remove bolts (1) from the cylinder head. Remove cylinder head (2) and the gasket from the crankcase. 3. Remove inlet valve springs (7).4. Remove (discharge) valve seats (6) from the cylinder head. Remove valves (8) and springs (5).5. Inspect the valve seats for damage and wear. Make replacements if necessary. 6. Remove valve stops (9) as follows: a) Put the machined surface of the cylinder head down on an arbor press.b) Gradually push the stops from the top of the cylinder head and out of the bottom.c) Be sure there is enough clearance for the stops between the press and the bottom of the cylinder head.d) Inspect the stop bore in the cylinder head. Make a replacement of the head body if the bore is damaged. Remove the valve stops only if there is wear and damage, also if the valve movement (travel) exceeds .057 in. (1.45 mm).7. Remove bolts (3) from the adapter. Remove adapters (4) from the compressor housing. 8. Remove O-ring seal (10), the thrust washer and the bearing from the adapter with tool (A).9. Remove bolts (12) from the cover. Remove cover (11) and the gasket from the crankcase. 10. Bend down the lock on lock straps (13). Remove bolts (14) from the bearing caps.11. Put identification on the bearing caps for correct installation with the connecting rod. Remove the bearing caps. 12. Remove pistons (15) from the crankcase through the top of the cylinders.13. Remove crankshaft (16) from the crankcase. Remove the key from the crankshaft. 14. Remove end cover (17) from the crankcase. Remove the O-ring seal, the thrust washer and the bearing.15. Remove cover (18), the gasket and the strainer from the air inlet opening. 16. Remove inlet valves (20) from their guides (21). Remove the inlet valve guides from around the inlet valve seats.

Be careful not to cause damage to the inlet valve seats.

17. Remove (unloader) spring (19), spring saddle (22) and the spring seat from the housing with needle nose pliers. 18. Remove (unloader) plunger (24) and guides (25) from the housing. Remove the guides from the plungers to plungers.19. To remove (unloader) pistons (23) from the bore, put a cover over the inlet

1. Put air compressor (1) and the gasket in position on the flywheel housing. Install the three bolts, lockwashers and nuts to hold it. 2. Connect hose assemblies (2) and (5) to the air compressor. Connect hose assembly (4) and tube assembly (3) to the engine.3. Fill the cooling system with coolant to the correct level.Disassemble Air Compressor

start by:a) remove air compressorb) remove accessory drive1. Remove the water line elbow, the air line elbows and oil (drain) tube from the air compressor. 2. Remove bolts (1) from the cylinder head. Remove cylinder head (2) and the gasket from the crankcase. 3. Remove inlet valve springs (7).4. Remove (discharge) valve seats (6) from the cylinder head. Remove valves (8) and springs (5).5. Inspect the valve seats for damage and wear. Make replacements if necessary. 6. Remove valve stops (9) as follows: a) Put the machined surface of the cylinder head down on an arbor press.b) Gradually push the stops from the top of the cylinder head and out of the bottom.c) Be sure there is enough clearance for the stops between the press and the bottom of the cylinder head.d) Inspect the stop bore in the cylinder head. Make a replacement of the head body if the bore is damaged. Remove the valve stops only if there is wear and damage, also if the valve movement (travel) exceeds .057 in. (1.45 mm).7. Remove bolts (3) from the adapter. Remove adapters (4) from the compressor housing. 8. Remove O-ring seal (10), the thrust washer and the bearing from the adapter with tool (A).9. Remove bolts (12) from the cover. Remove cover (11) and the gasket from the crankcase. 10. Bend down the lock on lock straps (13). Remove bolts (14) from the bearing caps.11. Put identification on the bearing caps for correct installation with the connecting rod. Remove the bearing caps. 12. Remove pistons (15) from the crankcase through the top of the cylinders.13. Remove crankshaft (16) from the crankcase. Remove the key from the crankshaft. 14. Remove end cover (17) from the crankcase. Remove the O-ring seal, the thrust washer and the bearing.15. Remove cover (18), the gasket and the strainer from the air inlet opening. 16. Remove inlet valves (20) from their guides (21). Remove the inlet valve guides from around the inlet valve seats.

Be careful not to cause damage to the inlet valve seats.

17. Remove (unloader) spring (19), spring saddle (22) and the spring seat from the housing with needle nose pliers. 18. Remove (unloader) plunger (24) and guides (25) from the housing. Remove the guides from the plungers to plungers.19. To remove (unloader) pistons (23) from the bore, put a cover over the inlet