Rating:

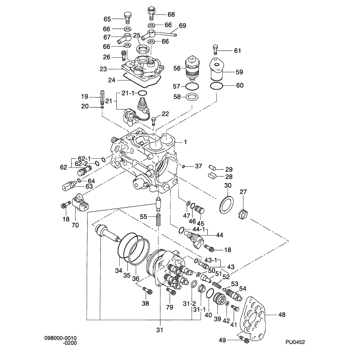

Information shim, lift adjusti Denso

Include in ##:

09800-00010

as SHIM, LIFT ADJUSTI

Cross reference number

Part num

Firm num

Firm

Name

09838-30680

SHIM, LIFT ADJUSTI

Information:

Pull-Down RPM Check

The engine must give rated horsepower for this test to have accuracy.1. Actuate the brakes, put the transmission in NEUTRAL and operate the engine at high idle rpm (accelerator pedal all the way down).2. Make a record of the engine rpm.3. Put the BrakeSaver control to the full ON position.4. Make a record of the engine rpm with the BrakeSaver full on.5. The engine rpm with the BrakeSaver full on must be 175 25 rpm less than the engine rpm with the BrakeSaver off. If the difference in rpm is less than 150 rpm, the BrakeSaver is not giving full braking force. If the difference in rpm is more than 200 rpm, check the air pressure to the BrakeSaver control valve. The air pressure must not be more than 42 psi (290 kPa).

Do not run the engine at high idle rpm with the BrakeSaver ON for more than 15 seconds at a time. Let the engine run at low idle with the BrakeSaver off for five minutes to keep from getting the engine cooling system too hot.

Klunk Check (check for free movement of the valve spool)

1. Run the engine until the truck air system is at its maximum pressure and then stop the engine.2. Put the BrakeSaver in the full ON position before the air pressure in the truck air system gets below 70 psi (480 kPa).3. Put the BrakeSaver in the OFF position. A noise ("klunk") must be heard at the BrakeSaver control valve as the valve spool hits the cover at the air inlet end of the control valve.4. If the noise is not heard at the BrakeSaver control valve, remove and disassemble the control valve. Inspect the valve for: a. A damaged valve body.b. Damaged or worn springs in the valve spool.c. Damaged or worn valve spool.d. Damaged or worn O-ring seals or diaphragm in the control valve.e. Closed holes (small holes to feel pressure) in the side of the valve spool.For specific problems, make reference to the PROBLEM INDEX below.

1. Air pressure to control valve. 2. Oil pressure to engine. 3. Oil pressure from oil cooler. 4. Oil pressure to BrakeSaver. 5. Oil pressure from BrakeSaver. 6. Oil pressure from engine. 7. Oil pressure to oil cooler. Fuel System

Difficulty within the fuel system can be classed in one of two groups: lack of fuel or too much fuel for proper combustion.Many times, the fuel system is blamed when the fault lies elsewhere, especially when smoky exhaust is the problem. Smoky exhaust can be the result of a faulty fuel injection valve, but it can also be caused by lack of air for complete combustion, overloading at high altitude, excessive oil burning or lack of compression.Visual Inspection

1. Observe the fuel pressure gauge reading. Lack of pressure indicates difficulty in the supply side of the system.2. Check the fuel level in the supply tank and the fuel tank cap vent for being plugged.3. See that the vent valve is closed.4. Check for

The engine must give rated horsepower for this test to have accuracy.1. Actuate the brakes, put the transmission in NEUTRAL and operate the engine at high idle rpm (accelerator pedal all the way down).2. Make a record of the engine rpm.3. Put the BrakeSaver control to the full ON position.4. Make a record of the engine rpm with the BrakeSaver full on.5. The engine rpm with the BrakeSaver full on must be 175 25 rpm less than the engine rpm with the BrakeSaver off. If the difference in rpm is less than 150 rpm, the BrakeSaver is not giving full braking force. If the difference in rpm is more than 200 rpm, check the air pressure to the BrakeSaver control valve. The air pressure must not be more than 42 psi (290 kPa).

Do not run the engine at high idle rpm with the BrakeSaver ON for more than 15 seconds at a time. Let the engine run at low idle with the BrakeSaver off for five minutes to keep from getting the engine cooling system too hot.

Klunk Check (check for free movement of the valve spool)

1. Run the engine until the truck air system is at its maximum pressure and then stop the engine.2. Put the BrakeSaver in the full ON position before the air pressure in the truck air system gets below 70 psi (480 kPa).3. Put the BrakeSaver in the OFF position. A noise ("klunk") must be heard at the BrakeSaver control valve as the valve spool hits the cover at the air inlet end of the control valve.4. If the noise is not heard at the BrakeSaver control valve, remove and disassemble the control valve. Inspect the valve for: a. A damaged valve body.b. Damaged or worn springs in the valve spool.c. Damaged or worn valve spool.d. Damaged or worn O-ring seals or diaphragm in the control valve.e. Closed holes (small holes to feel pressure) in the side of the valve spool.For specific problems, make reference to the PROBLEM INDEX below.

1. Air pressure to control valve. 2. Oil pressure to engine. 3. Oil pressure from oil cooler. 4. Oil pressure to BrakeSaver. 5. Oil pressure from BrakeSaver. 6. Oil pressure from engine. 7. Oil pressure to oil cooler. Fuel System

Difficulty within the fuel system can be classed in one of two groups: lack of fuel or too much fuel for proper combustion.Many times, the fuel system is blamed when the fault lies elsewhere, especially when smoky exhaust is the problem. Smoky exhaust can be the result of a faulty fuel injection valve, but it can also be caused by lack of air for complete combustion, overloading at high altitude, excessive oil burning or lack of compression.Visual Inspection

1. Observe the fuel pressure gauge reading. Lack of pressure indicates difficulty in the supply side of the system.2. Check the fuel level in the supply tank and the fuel tank cap vent for being plugged.3. See that the vent valve is closed.4. Check for