Rating:

Information shim, plunger spri Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Hacus - Forklift FPE238381 Shim, Plunger SPRI 13Z Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Include in ##:

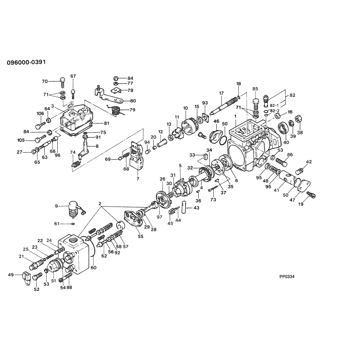

09600-00390

as SHIM, PLUNGER SPRI

Cross reference number

Part num

Firm num

Firm

Name

09624-80080

22182-1701

SHIM, PLUNGER SPRI

0962480080

22182-17010

TOYOTA

SHIM, PLUNGER SPRI

0962480080

22182-17010

TOYOTA

SHIM, PLUNGER SPRI

0962480080

22188-54010

TOYOTA

SHIM, PLUNGER SPRI

0962480080

8-97141272-0

ISUZU

SHIM, PLUNGER SPRI

0962480080

ME736400

MITSUBISHI

SHIM, PLUNGER SPRI

0962480080

S501 24 088

MAZDA

SHIM, PLUNGER SPRI

Information:

When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt is less as the angle between the supporting members and the object becomes less than 90°. Eyebolts and brackets should never be bent and should only be loaded in tension.

Use a hoist to remove heavy components. Lift the engine by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other, and as near perpendicular as possible to the top of the object being lifted.Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling. To remove the engine, use the two lifting eyes on the engine.Lifting eyes are designed for the arrangement as sold. Alterations to lifting eyes and/or arrangement weight make the lifting devices obsolete.If you make alterations, you are responsible for providing adequate lifting devices.Engine Storage

If the engine is not started for several weeks, the lubricating oil will drain from the cylinder walls and piston rings. Rust can form on the cylinder liner surface, which will increase engine wear and result in shorter engine life.To prevent excessive engine wear:

Be sure all lubrication recommendations mentioned in the Maintenance Management Schedule intervals chart are completed.If freezing temperatures can be expected, check the cooling system for adequate protection against freezing. A 50/50 solution of Caterpillar permanent-type antifreeze and approved water will give protection below -20°F (-29°C).If it will be impossible to start the engine every week, consult your Caterpillar dealer for instructions to prepare your engine for longer storage periods.If an engine remains out of service and its use is not immediately planned, special precautions should be taken.Refer to "Storage Procedures For Caterpillar Products," Form SEHS9031 for more detailed information on engine storage.