Rating:

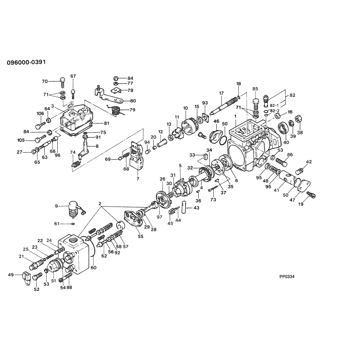

Information shim, plunger spri Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$40.69

18 Feb 2025

0.01[0.00] pounds

Amazon.com

Hacus - Forklift FPE261899 Shim, Plunger SPRI 13Z Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Include in ##:

09600-00390

as SHIM, PLUNGER SPRI

Cross reference number

Part num

Firm num

Firm

Name

09624-80060

22187-5401

SHIM, PLUNGER SPRI

0962480060

22187-54010

TOYOTA

SHIM, PLUNGER SPRI

0962480060

22187-54010

TOYOTA

SHIM, PLUNGER SPRI

0962480060

8-97141270-0

ISUZU

SHIM, PLUNGER SPRI

0962480060

ME736398

MITSUBISHI

SHIM, PLUNGER SPRI

0962480060

S501 24 086

MAZDA

SHIM, PLUNGER SPRI

Information:

Engine Operating Cost Summary

The Operating Cost Summary section is exactly what it implies, a summary. Here the total dollar expense and percentage of the total operating expense is calculated for each of the eight subsections listed in the Engine Operating Information section. The eight individual elements are then totaled and divided by the ownership period to yield the cost per mile (km), hour or day. Similar calculations are also made for only the maintenance and repair portion of the total operating cost.An Engine Operating Cost Analysis is a useful tool that can be used to:* Project the expected operating cost of a Caterpillar truck engine.* Identify the impact of individual elements on engine operating costs.* Determine expected operating costs if Caterpillar service and overhaul recommendations are followed.* Determine the cost per mile (km) or hour figures that you can obtain by having your dealer perform various levels of preventive maintenance as recommended by Caterpillar.* Determine the savings to be realized if Caterpillar repair kits, exchange components, etc., are used by those of you who elect to perform your own maintenance.* Determine the proper way to realize full value of your Caterpillar Engine by utilizing genuine Caterpillar parts and following Caterpillar recommended guidelines for preventive maintenance and before failure repairs.In conclusion, an Engine Operating Cost Analysis is a tool that was designed to identify costly problem areas for the purpose of helping you reduce your operating costs.

The Operating Cost Summary section is exactly what it implies, a summary. Here the total dollar expense and percentage of the total operating expense is calculated for each of the eight subsections listed in the Engine Operating Information section. The eight individual elements are then totaled and divided by the ownership period to yield the cost per mile (km), hour or day. Similar calculations are also made for only the maintenance and repair portion of the total operating cost.An Engine Operating Cost Analysis is a useful tool that can be used to:* Project the expected operating cost of a Caterpillar truck engine.* Identify the impact of individual elements on engine operating costs.* Determine expected operating costs if Caterpillar service and overhaul recommendations are followed.* Determine the cost per mile (km) or hour figures that you can obtain by having your dealer perform various levels of preventive maintenance as recommended by Caterpillar.* Determine the savings to be realized if Caterpillar repair kits, exchange components, etc., are used by those of you who elect to perform your own maintenance.* Determine the proper way to realize full value of your Caterpillar Engine by utilizing genuine Caterpillar parts and following Caterpillar recommended guidelines for preventive maintenance and before failure repairs.In conclusion, an Engine Operating Cost Analysis is a tool that was designed to identify costly problem areas for the purpose of helping you reduce your operating costs.