Rating:

Information shim, plunger spri Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Hacus - Forklift FPE254925 Shim, Plunger SPRI 13Z Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Include in ##:

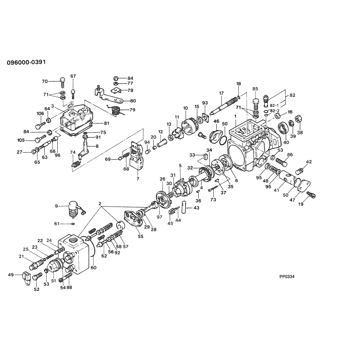

09600-00390

as SHIM, PLUNGER SPRI

Cross reference number

Part num

Firm num

Firm

Name

09624-80010

22182-5401

SHIM, PLUNGER SPRI

0962480010

22182-54010

TOYOTA

SHIM, PLUNGER SPRI

0962480010

22182-54010

TOYOTA

SHIM, PLUNGER SPRI

0962480010

8-97141265-0

ISUZU

SHIM, PLUNGER SPRI

0962480010

ME736393

MITSUBISHI

SHIM, PLUNGER SPRI

0962480010

S501 24 081

MAZDA

SHIM, PLUNGER SPRI

Information:

Scheduled Oil Sampling (S O S)

To compliment a good preventive maintenance program, Caterpillar recommends using S O S at regular scheduled intervals to monitor the condition and maintenance requirements of your engine.Obtain Sample

Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase.There are two methods recommended to obtain S O S samples from the 3176 engine crankcase. * Use the sampling valve installed on the 3176 for samples.* Use a sampling gun inserted into the sump.Caterpillar recommends using one of the above methods. If either of these methods are not possible, then use the drain stream method when changing oil. When using the drain stream to obtain the oil sample, do not sample from the first or final drain stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of the oil in the crankcase. Refer to "How to Take a Good Oil Sample," Form PEHP6001 for a step-by-step explanation if using this method of sampling crankcase oil.Use S O S at this scheduled interval to monitor the condition of and maintenance requirements for your engine. Consult your Caterpillar dealer for complete information and assistance in establishing an S O S program for your 3176 truck engine.Engine Oil and Filter(s)

Change Oil

The vehicle must be parked on a level surface to perform this maintenance procedure.

Refer to the "Lubricant Specifications" section of this manual for the recommended oil to use for this engine.Drain the crankcase with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. As the oil cools, suspended waste particles will settle on the bottom of the crankcase or oil pan and will not be removed with the draining oil.Failure to follow this recommended procedure would result in these waste particles being recirculated through your engine lubrication system with the new oil. 1. Remove the crankcase drain plug and allow the oil to drain.2. Install the crankcase drain plug and tighten it to 50 10 lb ft (70 14 N m).Change Filter(s)

1. Use a 2P8250 Filter Wrench to remove the oil filter (A) and optional bypass oil filter (B) (if equipped).

Element with debris.2. Use a 6V7905 Service Tool to cut the oil filter element open. Spread pleats apart and inspect the element for metal debris. An excessive amount of debris in the oil filter element may be indicative of a pending failure.Use a magnet to differentiate between the ferrous and non-ferrous metals found in your oil filter element.Ferrous metals may indicate wear on the steel and cast iron parts of your engine.Non-ferrous metals may indicate wear on the aluminum parts of your engine, such as main and rod bearings, turbocharger bearings and cylinder head wear.Due to normal wear, friction, etc., it is not uncommon to find small amounts of debris in your oil filter element. Consult your

To compliment a good preventive maintenance program, Caterpillar recommends using S O S at regular scheduled intervals to monitor the condition and maintenance requirements of your engine.Obtain Sample

Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase.There are two methods recommended to obtain S O S samples from the 3176 engine crankcase. * Use the sampling valve installed on the 3176 for samples.* Use a sampling gun inserted into the sump.Caterpillar recommends using one of the above methods. If either of these methods are not possible, then use the drain stream method when changing oil. When using the drain stream to obtain the oil sample, do not sample from the first or final drain stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of the oil in the crankcase. Refer to "How to Take a Good Oil Sample," Form PEHP6001 for a step-by-step explanation if using this method of sampling crankcase oil.Use S O S at this scheduled interval to monitor the condition of and maintenance requirements for your engine. Consult your Caterpillar dealer for complete information and assistance in establishing an S O S program for your 3176 truck engine.Engine Oil and Filter(s)

Change Oil

The vehicle must be parked on a level surface to perform this maintenance procedure.

Refer to the "Lubricant Specifications" section of this manual for the recommended oil to use for this engine.Drain the crankcase with the oil warm and the engine stopped to allow for the draining of waste particles that are suspended in the oil. As the oil cools, suspended waste particles will settle on the bottom of the crankcase or oil pan and will not be removed with the draining oil.Failure to follow this recommended procedure would result in these waste particles being recirculated through your engine lubrication system with the new oil. 1. Remove the crankcase drain plug and allow the oil to drain.2. Install the crankcase drain plug and tighten it to 50 10 lb ft (70 14 N m).Change Filter(s)

1. Use a 2P8250 Filter Wrench to remove the oil filter (A) and optional bypass oil filter (B) (if equipped).

Element with debris.2. Use a 6V7905 Service Tool to cut the oil filter element open. Spread pleats apart and inspect the element for metal debris. An excessive amount of debris in the oil filter element may be indicative of a pending failure.Use a magnet to differentiate between the ferrous and non-ferrous metals found in your oil filter element.Ferrous metals may indicate wear on the steel and cast iron parts of your engine.Non-ferrous metals may indicate wear on the aluminum parts of your engine, such as main and rod bearings, turbocharger bearings and cylinder head wear.Due to normal wear, friction, etc., it is not uncommon to find small amounts of debris in your oil filter element. Consult your