Rating:

Information shim Denso

Include in ##:

09130-00513

as SHIM

Cross reference number

Part num

Firm num

Firm

Name

09133-10220

SHIM

0913310220

22885-2550A

HINO

SHIM

0913310220

22885-2560A

HINO

SHIM

0913310220

22714-58231

TOYOTA

SHIM

0913310220

ME703161

MITSUBISHI

SHIM

0913310220

S2288-52560-A

HINO

SHIM

Information:

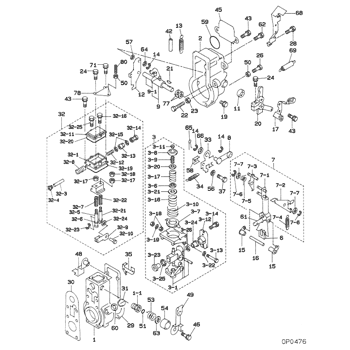

Illustration 74 g02026337 Appendix D

Cleaned Filter Specification

Note: Scope: The following steps determine a properly cleaned Caterpillar filter.Note: This specification applies to filters that were cleaned of ash only. This specification is only valid subsequent to the "Recommended Cleaning Procedure". This specification should not be used to determine if soot filled filters are properly cleaned. All filters must be baked appropriately using the "Recommended Cleaning Procedure" prior to application of this specification.HEALTH AND SAFETY

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Adhere to all local Health and Safety rules and regulations. Use all the personal protective equipment listed below:

Respirator

Safety shoes

Safety glasses

Latex gloves

Lab coatRESOURCESNecessary equipment:

38 cm (15 inch) long by 0.9 mm (0.04 inch) thick stainless steel probe for "200 cpsi" (Cells/Square inch) filters

Tape measureMETHODEvaluation of a cleaned filter:Note: A filter MUST meet all criteria in this section below to be considered clean.

Inspect both inlet and outlet surfaces for oil/fuel contamination, gouges and/or cracks. No cracks may be visible. Gouges may not be exceed 4.0 mm (0.15 inch) deep.

There must be no filter movement within the filters banding. This movement is defined as the substrate moving past the bent-over flange. The filter must be even or below the bent-over flange.

There must not be any signs of the steel fiber ring coming loose or any mat material (cottony gauze) slipping past the filter. See Illustration 75 below.

The flanges are not damaged beyond repair.

There are no dents deeper than 6.4 mm (0.25 inch) in the outer can of the filter and the outer can is not cracked, torn or otherwise breached.

No more than 20 cells are allowed to be damaged (showing soot) on the outlet face of the filter. Refer to Illustrations 76 and 77.

Inspect the ash depth in the cells using the "Check Cell Depth" instructions below.

Illustration 75 g02026392

Proper placement of the filter within the banding

(1) Outside Can

(2) Bent-over flange

(3) Steel fiber ring

(4) Mat material

(5) FilterNote: Filter must be below the bent over-flange (2).

Illustration 76 g02026398

Acceptable filter with less than 20 damaged cells

Illustration 77 g02026399

Unacceptable filter with too many damaged cells

Check Cell Depth

Check cell depth by dropping the stainless steel probe into a cell location noted by a dot in Illustration 78 below.

Lightly tap the probe with a finger until the probe does not travel into the cell any further. Mark the probe to record the depth.

Illustration 78 g02026405

Measure the distance from the tip of the probe which entered the cell to the mark made on the probe. This distance is the cell depth. Repeat this step 17 times per Illustration 78.

If the probe travels a minimum of 28.6 cm (11.25 inch) in all cells, the filter is considered clean.

If the probe encounters heavy resistance in