Rating:

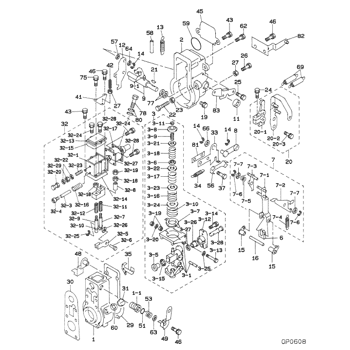

Information shaft, sliding wei Denso

Include in ##:

09130-03331

as SHAFT, SLIDING WEI

Cross reference number

Part num

Firm num

Firm

Name

09141-10450

22318-1450

SHAFT, SLIDING WEI

0914110450

22318-1450A

HINO

SHAFT, SLIDING WEI

0914110450

ME736992

MITSUBISHI

SHAFT, SLIDING WEI

0914110450

S2231-81450-A

HINO

SHAFT, SLIDING WEI

Information:

Biodiesel is a renewable fuel that can be made from vegetable oils, animal fat, and waste cooking oil. Soybean oil, rapeseed oil, and palm oil are some of the common vegetable oil sources. The raw oils or animal fats are chemically processed (esterified) to form a fatty acid methyl ester (referred to as FAME). The esterified product (FAME) is biodiesel fuel that can be used in compression ignition engines. Without the chemical processing referred to as esterification, the oils or fats are not suitable for use as fuel in compression ignition engines. The oil or fat must be esterified and the water and contaminants removed.Fuel made of 100 percent FAME is referred to as B100 biodiesel or neat biodiesel.Biodiesel can be blended with distillate diesel fuel. The blends can be used as fuel. The most commonly available biodiesel blends are B5, which is 5 percent biodiesel and 95 percent distillate diesel fuel. Also, B20, which is 20 percent biodiesel and 80 percent distillate diesel fuel. The percentages are volume-based.U.S. distillate diesel fuel specification "ASTM D975" includes up to B5 (5 percent) biodiesel. Any diesel fuel in the U.S. may contain up to B5 biodiesel fuel without labeling that indicates biodiesel content in the finished fuel.European distillate diesel fuel specification "EN 590" includes up to B5 (5 percent) biodiesel and in some regions up to B7 or B8 (7 or 8 percent by volume) biodiesel. Any diesel fuel in EU may contain up to these blend levels of biodiesel fuel without labeling that indicates biodiesel content in the finished fuel.Certain regions or countries around the world may mandate blend levels of B20 or higher. Refer to the local regulations and mandates and to local biodiesel specifications for fuel quality.Biodiesel fuel that is per Caterpillar and Industry recommended specifications (Refer to Table 2 in this Chapter) offers the following advantages:

Renewable fuel, nontoxic, and biodegradable

Reduces tailpipe particulate matter (PM), hydrocarbon (HC), and carbon monoxide (CO) emissions from most modern diesel engines

High lubricity, hence reduces friction

High cetane numberBiodiesel at B5 blend level has the same attributes as diesel fuel. At blend levels over B5, biodiesel has the following attributes that are different than diesel fuel and require management:

Energy density is lower than diesel fuel. At B100, biodiesel has about 8% lower energy density than diesel fuel. At B20 or lower blend levels, the energy density difference from diesel fuel is not significant.

Oxidation stability and storage stability are lower than diesel fuel.

Cold temperature operability is different than diesel fuel. Cloud point pour point and CFPP are typically higher than diesel fuel.

Materials compatibility is more restricted than diesel fuel.

A higher tendency to dissolve and absorb water than diesel fuel.

Metal content is higher than diesel fuel. Biodiesel can contain certain materials naturally or due to processing (phosphorus, sodium, calcium, potassium, and magnesium). The maximum levels of these materials are controlled by the appropriate specifications.

Contaminants content due to incomplete esterification or purifying process can be present. These contaminants may include glycerides, mono and diesters, sterol glucosides,

Renewable fuel, nontoxic, and biodegradable

Reduces tailpipe particulate matter (PM), hydrocarbon (HC), and carbon monoxide (CO) emissions from most modern diesel engines

High lubricity, hence reduces friction

High cetane numberBiodiesel at B5 blend level has the same attributes as diesel fuel. At blend levels over B5, biodiesel has the following attributes that are different than diesel fuel and require management:

Energy density is lower than diesel fuel. At B100, biodiesel has about 8% lower energy density than diesel fuel. At B20 or lower blend levels, the energy density difference from diesel fuel is not significant.

Oxidation stability and storage stability are lower than diesel fuel.

Cold temperature operability is different than diesel fuel. Cloud point pour point and CFPP are typically higher than diesel fuel.

Materials compatibility is more restricted than diesel fuel.

A higher tendency to dissolve and absorb water than diesel fuel.

Metal content is higher than diesel fuel. Biodiesel can contain certain materials naturally or due to processing (phosphorus, sodium, calcium, potassium, and magnesium). The maximum levels of these materials are controlled by the appropriate specifications.

Contaminants content due to incomplete esterification or purifying process can be present. These contaminants may include glycerides, mono and diesters, sterol glucosides,