Rating:

Information seat, spring, lwr Denso

Include in ##:

09010-04133

as SEAT, SPRING, LWR

Cross reference number

Part num

Firm num

Firm

Name

09016-50150

22122-1100

SEAT, SPRING, LWR

0901650150

22122-1100A

HINO

SEAT, SPRING, LWR

0901650150

22145-5C350

TOYOTA

SEAT, SPRING, LWR

0901650150

ME728609

MITSUBISHI

SEAT, SPRING, LWR

Information:

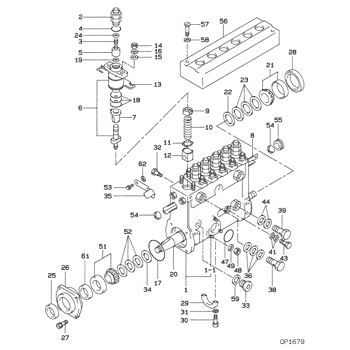

Fuel Injection Pump Operation

Fuel enters the fuel injection pump housing from the fuel filter through the fuel manifold and enters the fuel injection pump through the inlet port. The injection pump plungers and lifters are lifted by the cam lobes on the fuel system's own camshaft and always make a full stroke. The lifters are held against the cam lobes by springs. Each pump measures the amount of fuel to be injected into its respective cylinder and delivers it to the fuel injection nozzle.The amount of fuel pumped per stroke is varied by turning the plunger in the barrel. The plunger is turned by the governor action through the gear segmented sliding rack which turns the gear segment on the bottom of the pump plunger. The position of the scroll on the plunger determines the amount of fuel injected into the cylinders. Fuel Pump

Figures A, B and C illustrate the functioning of an injection pump as the plunger makes a stroke.In Fig. A the plunger is down and the inlet port is uncovered. Fuel flows into the space above the plunger through the slot and into the recess around the plunger.In Fig. B the plunger has started up and the port is covered. The fuel is trapped and will be forced through a check valve, fuel line, and injection valve.In Fig. C the plunger has risen until the port is uncovered by the recess in the plunger. The fuel can now escape back through the port into the fuel manifold and injection will cease.Note that the recess in the pump plunger forms a helix around the upper end of the plunger. Figures D, E and F illustrate how rotating the pump plunger affects the quantity of fuel injected.In Fig. D the plunger has been rotated into the shut-off position. The slot connecting the top of the plunger with the recess is in line with the port; therefore, no fuel can be trapped and injected.In Fig. E the plunger has been rotated into the idling position. The narrow part of the plunger formed by the helix will cover the port for only a short part of the stroke. This permits only a small amount of fuel to be injected per stroke.In Fig. F the plunger has been rotated into the full load position. The wide part of the plunger formed by the helix covers the port for a longer part of the stroke. This permits a larger amount of fuel to be injected per stroke. Fuel, under high pressure from the injection pumps, is transferred through the injection lines to the injection valves. As high pressure fuel enters the nozzle assembly, the check valve within the nozzle opens and permits the fuel to spray into the precombustion chamber where it mixes with the compressed air.The precombustion chamber serves several purposes: It provides an effective chamber for the mixing of fuel and air before it enters the cylinder for final combustion, thus permitting the use of a wider range

Fuel enters the fuel injection pump housing from the fuel filter through the fuel manifold and enters the fuel injection pump through the inlet port. The injection pump plungers and lifters are lifted by the cam lobes on the fuel system's own camshaft and always make a full stroke. The lifters are held against the cam lobes by springs. Each pump measures the amount of fuel to be injected into its respective cylinder and delivers it to the fuel injection nozzle.The amount of fuel pumped per stroke is varied by turning the plunger in the barrel. The plunger is turned by the governor action through the gear segmented sliding rack which turns the gear segment on the bottom of the pump plunger. The position of the scroll on the plunger determines the amount of fuel injected into the cylinders. Fuel Pump

Figures A, B and C illustrate the functioning of an injection pump as the plunger makes a stroke.In Fig. A the plunger is down and the inlet port is uncovered. Fuel flows into the space above the plunger through the slot and into the recess around the plunger.In Fig. B the plunger has started up and the port is covered. The fuel is trapped and will be forced through a check valve, fuel line, and injection valve.In Fig. C the plunger has risen until the port is uncovered by the recess in the plunger. The fuel can now escape back through the port into the fuel manifold and injection will cease.Note that the recess in the pump plunger forms a helix around the upper end of the plunger. Figures D, E and F illustrate how rotating the pump plunger affects the quantity of fuel injected.In Fig. D the plunger has been rotated into the shut-off position. The slot connecting the top of the plunger with the recess is in line with the port; therefore, no fuel can be trapped and injected.In Fig. E the plunger has been rotated into the idling position. The narrow part of the plunger formed by the helix will cover the port for only a short part of the stroke. This permits only a small amount of fuel to be injected per stroke.In Fig. F the plunger has been rotated into the full load position. The wide part of the plunger formed by the helix covers the port for a longer part of the stroke. This permits a larger amount of fuel to be injected per stroke. Fuel, under high pressure from the injection pumps, is transferred through the injection lines to the injection valves. As high pressure fuel enters the nozzle assembly, the check valve within the nozzle opens and permits the fuel to spray into the precombustion chamber where it mixes with the compressed air.The precombustion chamber serves several purposes: It provides an effective chamber for the mixing of fuel and air before it enters the cylinder for final combustion, thus permitting the use of a wider range