Rating:

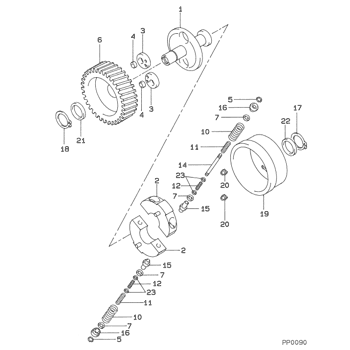

Information roller, timer Denso

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09188-20082

ME736962

ROLLER, TIMER

Information:

Hot oil and components can cause personal injury.Do not allow hot oil or components to contact skin.

Personal injury can result from hot coolant, steam and alkali.At operating temperature, engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot coolant or steam. Any contact can cause severe burns.Remove filler cap slowly to relieve pressure only when engine is stopped and radiator cap is cool enough to touch with your bare hand.Cooling System Conditioner contains alkali. Avoid contact with skin and eyes.

The technician making the repairs as outlined in this instruction MUST have completed all required training and testing. This includes any required technician certification training and EPA07 update assesment training and testing. The required EPA07 assesment video and test are posted on DLMS (Global On-Highway Campus). The Dealer MUST submit the technician's CWS ID on each Cat ET warranty report. The CWS ID must be placed in the "Technician Name" section of the warranty report in Cat ET (see example below). Dealer claim submittal for repairs in this update signifies that the repairs have been done completely by a trained technician. All claims that do not follow this rerequirement will be DENIED.

Illustration 1 g01738938

Caterpillar Electronic Technician warranty report

Review the SIMSi for any open Service Letters that can also be completed during this update. Do not perform any letters for software updates as you will be flashing new software in the Special Instruction.

Download a warranty report to SIMSi.

Document the serial number for the Diesel Particulate Filter (DPF) and record the serial number in the area for comments of the Warranty Report. Refer to Special Instruction, REHS3849 for the correct procedure.

Utilize Caterpillar Electronic Technician (ET) for any active diagnostic fault codes or logged diagnostic fault codes. Troubleshoot and resolve all active fault codes that are found before proceeding.

The inspection of the CGI actuator has been removed from the EPA07 Update Program. Due to the normal collection of debris around this actuator, the determination of a failure is not practical from a visual inspection alone. CGI actuators should not be replaced unless troubleshooting of the component identifies a failure of the CGI actuator.

Thoroughly wash the engine. This step will ensure that the following components are cleaned for the steps that follow: ARD fuel manifold, secondary fuel filter base, primary fuel filter base and all fuel connections.

Illustration 2 g01681836

(3) CGI flex pipe

Inspect the CGI flex pipe that is installed on all Kenworth and Peterbilt chassis. Check for a previous update to the CGI flex pipe under either a Peterbilt or Kenworth Technical Information BulletinThis work should be charged to your local OEM dealer with instructions that are provided with the service letter.

Peterbilt -Field Repair Notice 408-1 or newer Clean Gas Induction (CGI) and Main Exhaust Pipe Couplings

Kenworth – Technical Information Bulletin Number 43-12 or newer

Drain and save the coolant. The saved coolant can then be reused. Draining the coolant is necessary in order to replace the ARD combustion head.

Illustration 3 g01678253

(4) CGI coolant hose and clamps that