Rating:

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

8-9765106-5 Diesel Fuel Pump ,Compatible For Isuzu 6hk1 294050-0412 294050-0410

OJNNAVD The fuel pump assembly improves the efficiency and stability of fuel delivery. Precision manufacturing and testing, with the same quality as OE fuel pumps. || Design the product to operate under extreme temperature and low fuel conditions to ensure reliable performance and extended lifespan || Turbopump technology almost eliminates fuel pulsation, noise, and hot start issues in old pump designs || Please confirm if the product OE code is compatible with your car || 294050-0410 8-9765106-5 294050-0412

OJNNAVD The fuel pump assembly improves the efficiency and stability of fuel delivery. Precision manufacturing and testing, with the same quality as OE fuel pumps. || Design the product to operate under extreme temperature and low fuel conditions to ensure reliable performance and extended lifespan || Turbopump technology almost eliminates fuel pulsation, noise, and hot start issues in old pump designs || Please confirm if the product OE code is compatible with your car || 294050-0410 8-9765106-5 294050-0412

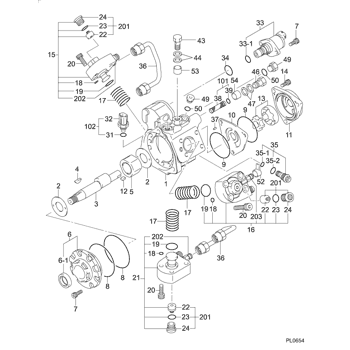

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29405-00412

PUMP ASSY, SUPPLY

HP4

1002--1201

8-97605106-6

ISUZU

Include in ##:

29405-00412

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29405-00412

8-97605106

PUMP ASSY, SUPPLY

Information:

Interval Categories

Engine components can generally be grouped into "speed sensitive" and "load sensitive" categories. Therefore, the maintenance interval for each item listed in the "Maintenance Management Schedule" is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items.Therefore, the maintenance intervals established for speed sensitive items are based on miles (kilometers) or service hours, whichever occurs first. Load sensitive items such as piston rings, cylinder liners, etc., are affected by the load on your engine during operation. Generally speaking, the lower the load, the longer the engine life and conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Therefore, the maintenance interval for load sensitive items also includes quantity of fuel used, since the amount of fuel consumed is directly related to the load on your engine.Load sensitive items are normally internal engine components. The amount of fuel consumed is directly related to the load on your engine. Since the amount of fuel consumed is a better indicator of performing an overhaul than miles (kilometers) or service hours, Caterpillar recommends performing an overhaul on these items at the specified maintenance interval based on the quantity of fuel consumed.Interval to Overhaul

The specified overhaul interval for this engine rated 350 hp (261 kw) at 1800 rpm and below is "Every 100,000 Gallons (380 000 L) of Fuel or 600,000 Miles (960 000 km) or 10,000 Service Hours." This includes all power ratings BELOW 350 hp (261 kw).The specified overhaul interval for this engine rated 350 hp (261 kw) at 2100 rpm and up is "Every 100,000 Gallons (380 000 L) of Fuel or 500,000 Miles (800 000 km) or 10,000 Service Hours." This includes all power ratings ABOVE 350 hp (261 kw). Two Maintenance Management charts follow. Ensure the correct chart is selected for the engine being maintained. PM Level means Preventive Maintenance Level.

Engine components can generally be grouped into "speed sensitive" and "load sensitive" categories. Therefore, the maintenance interval for each item listed in the "Maintenance Management Schedule" is primarily based on the item and its relationship to either engine speed or load. Speed sensitive items such as water pumps, air compressors, etc., are not primarily affected by the load on your engine during operation. The load on an engine will not significantly accelerate the repair or replacement cycle for speed sensitive items.Therefore, the maintenance intervals established for speed sensitive items are based on miles (kilometers) or service hours, whichever occurs first. Load sensitive items such as piston rings, cylinder liners, etc., are affected by the load on your engine during operation. Generally speaking, the lower the load, the longer the engine life and conversely, the higher the load, the shorter the engine life. A heavy load on an engine will accelerate the repair or replacement cycle for load sensitive items.Therefore, the maintenance interval for load sensitive items also includes quantity of fuel used, since the amount of fuel consumed is directly related to the load on your engine.Load sensitive items are normally internal engine components. The amount of fuel consumed is directly related to the load on your engine. Since the amount of fuel consumed is a better indicator of performing an overhaul than miles (kilometers) or service hours, Caterpillar recommends performing an overhaul on these items at the specified maintenance interval based on the quantity of fuel consumed.Interval to Overhaul

The specified overhaul interval for this engine rated 350 hp (261 kw) at 1800 rpm and below is "Every 100,000 Gallons (380 000 L) of Fuel or 600,000 Miles (960 000 km) or 10,000 Service Hours." This includes all power ratings BELOW 350 hp (261 kw).The specified overhaul interval for this engine rated 350 hp (261 kw) at 2100 rpm and up is "Every 100,000 Gallons (380 000 L) of Fuel or 500,000 Miles (800 000 km) or 10,000 Service Hours." This includes all power ratings ABOVE 350 hp (261 kw). Two Maintenance Management charts follow. Ensure the correct chart is selected for the engine being maintained. PM Level means Preventive Maintenance Level.