Rating:

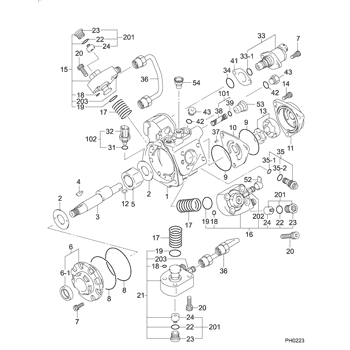

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL L6

Engine

L6

Serial start-end

0809-

Info

Injector Nozzle

JOHN DEERE

PUMP ASSY, SUPPLY

NB

- #..SWITCHED TO DMHU PRODUCTION FROM 1204

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

YRGGHUI Diesel Injector Pump Fuel Injection Pump 294050-0300 294050-0320 294050-0321,Compatible for FAW Bus CA6DL1

YRGGHUI OEM NO. : 294050-0300 294050-0320 294050-0321 || Types of automotive components: fuel pump, diesel pump, high-pressure fuel pump components, fuel pump components || Fuel pump: can enhance power, reduce fuel consumption, provide strong power, accelerate smoothly, and ensure the stability of the fuel pump at high temperatures. Make your car full of power || Before purchasing a fuel pump, please confirm if the picture and OEM number match your part! This is really important! If they are not the same component, they cannot be used! All products undergo testing before shipment!! || If you have any questions, please feel free to contact us and we will reply within 24 hours. Please confirm the product based on your vehicle model, year, code, and tag number. thank you. Automotive parts have accurate OEM numbers. Please ensure that the OEM number is suitable for your car

YRGGHUI OEM NO. : 294050-0300 294050-0320 294050-0321 || Types of automotive components: fuel pump, diesel pump, high-pressure fuel pump components, fuel pump components || Fuel pump: can enhance power, reduce fuel consumption, provide strong power, accelerate smoothly, and ensure the stability of the fuel pump at high temperatures. Make your car full of power || Before purchasing a fuel pump, please confirm if the picture and OEM number match your part! This is really important! If they are not the same component, they cannot be used! All products undergo testing before shipment!! || If you have any questions, please feel free to contact us and we will reply within 24 hours. Please confirm the product based on your vehicle model, year, code, and tag number. thank you. Automotive parts have accurate OEM numbers. Please ensure that the OEM number is suitable for your car

YRGGHUI Diesel Injector Pump Fuel Injection Pump 294050-0300 294050-0320 294050-0321,Compatible for FAW Bus CA6DL1

YRGGHUI OEM NO. : 294050-0300 294050-0320 294050-0321 || Types of automotive components: fuel pump, diesel pump, high-pressure fuel pump components, fuel pump components || Fuel pump: can enhance power, reduce fuel consumption, provide strong power, accelerate smoothly, and ensure the stability of the fuel pump at high temperatures. Make your car full of power || Before purchasing a fuel pump, please confirm if the picture and OEM number match your part! This is really important! If they are not the same component, they cannot be used! All products undergo testing before shipment!! || If you have any questions, please feel free to contact us and we will reply within 24 hours. Please confirm the product based on your vehicle model, year, code, and tag number. thank you. Automotive parts have accurate OEM numbers. Please ensure that the OEM number is suitable for your car

YRGGHUI OEM NO. : 294050-0300 294050-0320 294050-0321 || Types of automotive components: fuel pump, diesel pump, high-pressure fuel pump components, fuel pump components || Fuel pump: can enhance power, reduce fuel consumption, provide strong power, accelerate smoothly, and ensure the stability of the fuel pump at high temperatures. Make your car full of power || Before purchasing a fuel pump, please confirm if the picture and OEM number match your part! This is really important! If they are not the same component, they cannot be used! All products undergo testing before shipment!! || If you have any questions, please feel free to contact us and we will reply within 24 hours. Please confirm the product based on your vehicle model, year, code, and tag number. thank you. Automotive parts have accurate OEM numbers. Please ensure that the OEM number is suitable for your car

Diesel Injector Pump Fuel Injection Pump 294050-0300 294050-0320 294050-0321 Compatible For FAW BUS CA6DL1

VXRWKZEO Diesel Injector Pump Fuel Injection Pump 294050-0300 294050-0320 294050-0321 Compatible For FAW BUS CA6DL1 || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

VXRWKZEO Diesel Injector Pump Fuel Injection Pump 294050-0300 294050-0320 294050-0321 Compatible For FAW BUS CA6DL1 || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29405-00300

PUMP ASSY, SUPPLY

HP4

-1004

Include in ##:

29405-00300

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29405-00300

JOHN DEERE

PUMP ASSY, SUPPLY

2940500300

RE537393

JOHN DEERE

PUMP ASSY SUPPLY

Test Calibration Data:

02EO030000

02EO030000

02EO030000

Information:

Engine Crankcase

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the oil system.

Check Oil Level

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to calibrating the oil level gauge in the Dipsticks section of this manual or consult your Caterpillar dealer before operating the engine. 3. Add oil if necessary. See Refill Capacities and Lubricant Specifications for the size of your engine crankcase and proper oil to use. Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary filters, refer to the OEM or manufacturer's instructions.Leaks and Loose Connections

Inspect the Engine

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before servicing. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the oil system.

Check Oil Level

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to calibrating the oil level gauge in the Dipsticks section of this manual or consult your Caterpillar dealer before operating the engine. 3. Add oil if necessary. See Refill Capacities and Lubricant Specifications for the size of your engine crankcase and proper oil to use. Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary filters, refer to the OEM or manufacturer's instructions.Leaks and Loose Connections

Inspect the Engine

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before servicing. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses