Rating:

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

agricultural machine S450

Engine

S450

Serial start-end

1204-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

294050-0060 Fuel Pump RE534156 RE546126 RE519597 2940500065 2940500064 Compatible For John Deere Denso HP4 Common Rail Fuel Injector Pump

UCLMCNID Made of high-performance alloys, it is wear-resistant and corrosion-resistant, extending its service life. || Using our product can fully atomize fuel, promote complete combustion, and improve fuel economy. || The internal fuel flow channel has been optimized to reduce pressure loss. || It can maintain a stable working state under various working conditions. || 294050-0060 Fuel Pump RE534156 RE546126 RE519597 2940500065 2940500064 Compatible For John Deere Denso HP4 Common Rail Fuel Injector Pump

UCLMCNID Made of high-performance alloys, it is wear-resistant and corrosion-resistant, extending its service life. || Using our product can fully atomize fuel, promote complete combustion, and improve fuel economy. || The internal fuel flow channel has been optimized to reduce pressure loss. || It can maintain a stable working state under various working conditions. || 294050-0060 Fuel Pump RE534156 RE546126 RE519597 2940500065 2940500064 Compatible For John Deere Denso HP4 Common Rail Fuel Injector Pump

HP4 Diesel Common Rail Fuel Injection Pump RE546126 294050-0064 294050-0065 SE501922 Compatible For John Deere

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || HP4 Diesel Common Rail Fuel Injection Pump RE546126 294050-0064 294050-0065 SE501922 Compatible For John Deere

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || HP4 Diesel Common Rail Fuel Injection Pump RE546126 294050-0064 294050-0065 SE501922 Compatible For John Deere

WZCNLXLX HP4 Fuel Injection Pump RE546126 294050-0064 294050-0065 SE501922 For JD Engine

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:RE546126 294050-0064 294050-0065 SE501922 || Application:For JD Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:RE546126 294050-0064 294050-0065 SE501922 || Application:For JD Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

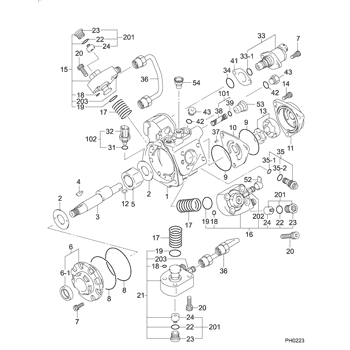

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

29405-00065

PUMP ASSY, SUPPLY

Information:

1. Loosen the tension on water pump drive V-belt (1), and remove it from the engine. Remove eight bolts (2) and damper (3) from the crankshaft pulley. 2. Remove four bolts (4), the washer and crankshaft pulley (5) from the end of the crankshaft. 3. Carefully make three evenly spaced holes in the crankshaft front seal with a hammer and sharp punch. Use Tool (A) to remove crankshaft front seal (1). Do not damage the flange of the crankshaft during seal removal. The following steps are for the installation of the vibration damper, crankshaft pulley and crankshaft front seal.4. Be sure the flange of the crankshaft is thoroughly clean prior to installing the crankshaft front seal and the crankshaft pulley. 5. With the shipping sleeve in position, install the crankshaft front seal using Tool (B). The distance between the front face of the crankshaft front seal and the front face of the front housing must be 2.5 0.5 mm (.10 .02 in) after seal installation. See the topic "Crankshaft Seals" in the 3114 & 3116 Diesel Truck Engines Specifications module, Form No. SENR6436 for further details.6. Remove the shipping sleeve from the crankshaft front seal. Apply clean engine oil to the surface of the crankshaft pulley that makes contact with the crankshaft front seal.7. Put crankshaft pulley (5) in position on the crankshaft, and install the washer and four bolts (4) that hold it. Tighten the bolts to a torque of 190 30 N m (140 22 lb ft).8. Install water pump drive V-belt (1).9. Adjust the tension of water pump drive V-belt (1). See the topic "Alternator And Fan Drive Belts, Inspect/Adjust/Replace" in the 3114 & 3116 ATAAC Diesel Truck Engine Operation & Maintenance Manual, Form No. SEBU6723. Also, refer to the "Belt Tension Chart" in the 3114 & 3116 Diesel Truck Engines Specifications module, Form No. SENR6436.