Rating:

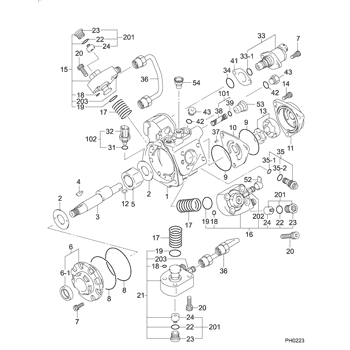

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

agricultural machine S450

Engine

S450

Serial start-end

1204-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump RE534165 for John Deere Engine 6090 Harvester 1270D 1710D 1711D

FGNTWP Part Number:RE534165, RE519597, 294050-006, 294050006, 294050-0060, 2940500060, 294050-0061, 2940500061, 294050-0062, 2940500062, 294050-0063, 2940500063, 294050-0064, 2940500064, 294050-0065, 2940500065, 294050-0066, 2940500066, 294050 -0067, 2940500067, 294050-0068, 2940500068, 294050-0069, 2940500069 || Applications:Fit For John Deere Tractor: S450 || Application:Fit For John Deere Harvester: 1270D, 1710D, 1711D

FGNTWP Part Number:RE534165, RE519597, 294050-006, 294050006, 294050-0060, 2940500060, 294050-0061, 2940500061, 294050-0062, 2940500062, 294050-0063, 2940500063, 294050-0064, 2940500064, 294050-0065, 2940500065, 294050-0066, 2940500066, 294050 -0067, 2940500067, 294050-0068, 2940500068, 294050-0069, 2940500069 || Applications:Fit For John Deere Tractor: S450 || Application:Fit For John Deere Harvester: 1270D, 1710D, 1711D

Common Rail Fuel Pump Injector 2940500065 2940500064 2940500060 RE534156 RE546126 RE519597 Compatible With John Deere Denso HP4(2940500064)

Adfghjk COMPATIBLE WITH JOHN DEERE HP4 ENGINE: Common Rail Fuel Injection Pump Assembly 2940500065, Compatible with John Deere Denso HP4 engine, remanufactured to original factory specifications, ISO certified tested. || High Pressure Performance Certified: The remanufacturing process includes 250Bar high pressure testing with ≤0.5% error in injection accuracy and 98% performance to new part standards. || Upgrade of key components: Replacement of Denso's original plunger assembly and sealing ring improves abrasion resistance by 40% and eliminates the risk of fuel leakage. || Full-process quality control: 12 quality control procedures, including 3 pressure cycle tests and ECU compatibility verification, to ensure ready-to-use. || Environmental compliance: EPA/CE remanufacturing standards, fits 2010-2020 HP4 engines, includes installation guide and 90-day warranty.

Adfghjk COMPATIBLE WITH JOHN DEERE HP4 ENGINE: Common Rail Fuel Injection Pump Assembly 2940500065, Compatible with John Deere Denso HP4 engine, remanufactured to original factory specifications, ISO certified tested. || High Pressure Performance Certified: The remanufacturing process includes 250Bar high pressure testing with ≤0.5% error in injection accuracy and 98% performance to new part standards. || Upgrade of key components: Replacement of Denso's original plunger assembly and sealing ring improves abrasion resistance by 40% and eliminates the risk of fuel leakage. || Full-process quality control: 12 quality control procedures, including 3 pressure cycle tests and ECU compatibility verification, to ensure ready-to-use. || Environmental compliance: EPA/CE remanufacturing standards, fits 2010-2020 HP4 engines, includes installation guide and 90-day warranty.

ZGZJYBL HP4 Fuel Injection Pump For JD EngineRE546126 294050-0064 294050-0065 SE501922

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:RE546126 294050-0064 294050-0065 SE501922 || Application:For JD Engine || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:RE546126 294050-0064 294050-0065 SE501922 || Application:For JD Engine || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

29405-00065

PUMP ASSY, SUPPLY

Information:

1. Loosen the tension on water pump drive V-belt (1), and remove it from the engine. Remove eight bolts (2) and damper (3) from the crankshaft pulley. 2. Remove four bolts (4), the washer and crankshaft pulley (5) from the end of the crankshaft. 3. Carefully make three evenly spaced holes in the crankshaft front seal with a hammer and sharp punch. Use Tool (A) to remove crankshaft front seal (1). Do not damage the flange of the crankshaft during seal removal. The following steps are for the installation of the vibration damper, crankshaft pulley and crankshaft front seal.4. Be sure the flange of the crankshaft is thoroughly clean prior to installing the crankshaft front seal and the crankshaft pulley. 5. With the shipping sleeve in position, install the crankshaft front seal using Tool (B). The distance between the front face of the crankshaft front seal and the front face of the front housing must be 2.5 0.5 mm (.10 .02 in) after seal installation. See the topic "Crankshaft Seals" in the 3114 & 3116 Diesel Truck Engines Specifications module, Form No. SENR6436 for further details.6. Remove the shipping sleeve from the crankshaft front seal. Apply clean engine oil to the surface of the crankshaft pulley that makes contact with the crankshaft front seal.7. Put crankshaft pulley (5) in position on the crankshaft, and install the washer and four bolts (4) that hold it. Tighten the bolts to a torque of 190 30 N m (140 22 lb ft).8. Install water pump drive V-belt (1).9. Adjust the tension of water pump drive V-belt (1). See the topic "Alternator And Fan Drive Belts, Inspect/Adjust/Replace" in the 3114 & 3116 ATAAC Diesel Truck Engine Operation & Maintenance Manual, Form No. SEBU6723. Also, refer to the "Belt Tension Chart" in the 3114 & 3116 Diesel Truck Engines Specifications module, Form No. SENR6436.