Rating:

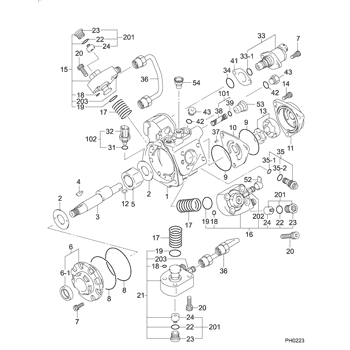

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

294050-0062 Diesel Engine Parts Pressure Fuel Injection Pump RE546126 RE534156 294050-0062

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

294050-0060 294050-0061 294050-0062 RE519597 RE534156 Fuel Injection Pump for John Deere 6090 9.0L Engine S450 Tractor 1270D 1710D 1711D Harvester

HIRINTOL 🔸Replace Part Number: 294050-0060, 294050-0061, 294050-0062, RE519597, RE534156 || 🔸Engine Model: for John Deere Engine 6090, 6090HTJ02, 6090HTJ01; for Isuzu 6HK1 Engine || 🔸Compatible Model: for John Deere Harvester 1270D, 1710D, 1711D; for John Deere Tractor S450 || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions.

HIRINTOL 🔸Replace Part Number: 294050-0060, 294050-0061, 294050-0062, RE519597, RE534156 || 🔸Engine Model: for John Deere Engine 6090, 6090HTJ02, 6090HTJ01; for Isuzu 6HK1 Engine || 🔸Compatible Model: for John Deere Harvester 1270D, 1710D, 1711D; for John Deere Tractor S450 || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions.

Compatible with John Deere 9.0L Engine Fuel Injection Pump RE546126 294050-0061 294050-0062 294050-0063 294050-0064 294050-0065

KoovDem Part Number: RE546126 294050-0061 294050-0062 294050-0063 294050-0064 294050-0065 2940500061 2940500062 2940500063 2940500064 2940500065 || Part Name: RE546126 294050-0061 294050-0062 Fuel Injection Pump || Compatible with John Deere 9.0L Engine, this product meets high standards for reliable performance. Trustworthy and dependable, it enhances efficiency and longevity of equipment. Upgrade your machine for optimal compatibility. || Please verify the accurate part number instead of solely relying on the model number. || Please carefully review the product image and part number to ensure that it is the correct item before making a purchase. This will help prevent any unnecessary returns or exchanges.

KoovDem Part Number: RE546126 294050-0061 294050-0062 294050-0063 294050-0064 294050-0065 2940500061 2940500062 2940500063 2940500064 2940500065 || Part Name: RE546126 294050-0061 294050-0062 Fuel Injection Pump || Compatible with John Deere 9.0L Engine, this product meets high standards for reliable performance. Trustworthy and dependable, it enhances efficiency and longevity of equipment. Upgrade your machine for optimal compatibility. || Please verify the accurate part number instead of solely relying on the model number. || Please carefully review the product image and part number to ensure that it is the correct item before making a purchase. This will help prevent any unnecessary returns or exchanges.

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

29405-00062

PUMP ASSY, SUPPLY

Information:

Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Engine Air Cleaner - Check indicator, clean and replace elements, if necessary Air-to-Air Aftercooler System - Check, clean if necessaryPM Level 1

Every 2,000 gal (7580 L) of Fuel or 12,500 Miles (20 000 km) or 250 Hours* Scheduled Oil Sampling (S O S) Analysis -Obtain Engine Oil and Filter(s)2 - Replace 3 Fuel Filters - Replace final filter and Clean/Replace primary filter (if equipped) 3 Cooling System - Test for concentration/Add coolant additive or Replace supplemental additive element (if equipped) Crankcase Breather - Clean Alternator, Fan and Accessory Drive Belts -Inspect/Replace Hoses and Clamps - Inspect/Replace Air-to-Air Aftercooler System - Inspect/Check Cylinder Head Grounding Stud -Inspect/Clean/Tighten Engine Valve Lash (at Initial PM 1 Interval) -Check/Adjust Radiator Fins - Inspect/CheckPM Level 2

Every 26,600 gal (100 000 L) of Fuel or 166,000 Miles (267 250 km) or 3,330 Hours* Performance Analysis Report (PAR) - Obtain Engine - Steam clean Thermostat - Replace Cooling System - Clean/Flush Water Pump - Rebuild or Exchange Electronic Unit Injectors - Test Engine Valve Lash and Electronic Unit Injector Preload - Check/Adjust Jacobs Brake Slave Lash - Check/AdjustPM Level 3

Every 40,000 gal (151 600 L) of Fuel or 250,000 Miles (402 500 km) or 5,000 Hours* Air Compressor - Rebuild or Exchange Turbocharger - Rebuild or Exchange Engine Mounts - Inspect/Check Throttle Position Sensor - Check/Adjust calibrationOverhaul

Every 80,000 gal (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Hours* Overhaul Information Cylinder Head Assembly - Rebuild or Exchange Cylinder Packs - Exchange Spacer Block - Inspect Camshaft Followers - Inspect Oil Pump and Fuel Transfer Pump - Inspect Thrust, Main and Rod Bearings - Replace Valve Rotators - Replace Thermostat - Replace Throttle Position Sensor - Replace Crankshaft - Inspect Camshaft - Inspect Vibration Damper - Inspect Electronic Unit Injectors - Test Oil Cooler and Air-to-Air Aftercooler Core -Clean/Test*First Perform Previous Service Hour Items2Remote mounted or auxiliary filters require additional oil. When changing oil, overfill crankcase by amount needed for auxiliary system (if equipped).3To prevent crankshaft and/or bearing damage, crank engine to fill all filters before starting engine.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Engine Air Cleaner - Check indicator, clean and replace elements, if necessary Air-to-Air Aftercooler System - Check, clean if necessaryPM Level 1

Every 2,000 gal (7580 L) of Fuel or 12,500 Miles (20 000 km) or 250 Hours* Scheduled Oil Sampling (S O S) Analysis -Obtain Engine Oil and Filter(s)2 - Replace 3 Fuel Filters - Replace final filter and Clean/Replace primary filter (if equipped) 3 Cooling System - Test for concentration/Add coolant additive or Replace supplemental additive element (if equipped) Crankcase Breather - Clean Alternator, Fan and Accessory Drive Belts -Inspect/Replace Hoses and Clamps - Inspect/Replace Air-to-Air Aftercooler System - Inspect/Check Cylinder Head Grounding Stud -Inspect/Clean/Tighten Engine Valve Lash (at Initial PM 1 Interval) -Check/Adjust Radiator Fins - Inspect/CheckPM Level 2

Every 26,600 gal (100 000 L) of Fuel or 166,000 Miles (267 250 km) or 3,330 Hours* Performance Analysis Report (PAR) - Obtain Engine - Steam clean Thermostat - Replace Cooling System - Clean/Flush Water Pump - Rebuild or Exchange Electronic Unit Injectors - Test Engine Valve Lash and Electronic Unit Injector Preload - Check/Adjust Jacobs Brake Slave Lash - Check/AdjustPM Level 3

Every 40,000 gal (151 600 L) of Fuel or 250,000 Miles (402 500 km) or 5,000 Hours* Air Compressor - Rebuild or Exchange Turbocharger - Rebuild or Exchange Engine Mounts - Inspect/Check Throttle Position Sensor - Check/Adjust calibrationOverhaul

Every 80,000 gal (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Hours* Overhaul Information Cylinder Head Assembly - Rebuild or Exchange Cylinder Packs - Exchange Spacer Block - Inspect Camshaft Followers - Inspect Oil Pump and Fuel Transfer Pump - Inspect Thrust, Main and Rod Bearings - Replace Valve Rotators - Replace Thermostat - Replace Throttle Position Sensor - Replace Crankshaft - Inspect Camshaft - Inspect Vibration Damper - Inspect Electronic Unit Injectors - Test Oil Cooler and Air-to-Air Aftercooler Core -Clean/Test*First Perform Previous Service Hour Items2Remote mounted or auxiliary filters require additional oil. When changing oil, overfill crankcase by amount needed for auxiliary system (if equipped).3To prevent crankshaft and/or bearing damage, crank engine to fill all filters before starting engine.