Rating:

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

TRUCK 6M60T

Engine

6M60T

Serial start-end

0404-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel injection pump 294050-0040 294050-0041 294050-0042 294050-0043 294050-0044 Fits for Mitsubishi 6M60 6M60T Engine

Goruvhe ☝Part Name☝:Fuel Injection Pump || ☝Part Number☝:294050-0040 294050-0041 294050-0042 294050-0043 294050-0044 || ☝Application☝:Fits for Mitsubishi 6M60 6M60T Engine || NOTE: To avoid unavoidable returns! Before purchasing, please compare with the old parts and part numbers to verify their accuracy before making a purchase. || Tips: The product images are for reference only. If you find any discrepancies with your actual product, please contact us promptly and we will respond as soon as possible!

Goruvhe ☝Part Name☝:Fuel Injection Pump || ☝Part Number☝:294050-0040 294050-0041 294050-0042 294050-0043 294050-0044 || ☝Application☝:Fits for Mitsubishi 6M60 6M60T Engine || NOTE: To avoid unavoidable returns! Before purchasing, please compare with the old parts and part numbers to verify their accuracy before making a purchase. || Tips: The product images are for reference only. If you find any discrepancies with your actual product, please contact us promptly and we will respond as soon as possible!

Fuel injection Pump 294050-0042 ME302144 for Mitsubishi Engine 6M60 6M60T

100% Apollo part number: 294050-0042 ME302144 || application: for Mitsubishi Engine 6M60 6M60T

100% Apollo part number: 294050-0042 ME302144 || application: for Mitsubishi Engine 6M60 6M60T

HP4 Diesel Fuel Injection Injector Pump 294050-0041 294050-0042 294050-0043 294050-0044 294050-0040 Compatible For MITSUBISHI 6M60T

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

You can buy:

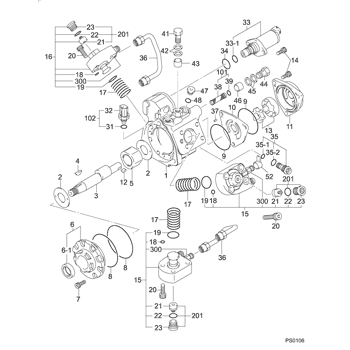

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29405-00042

PUMP ASSY, SUPPLY

HP4

0508--0902

ME304302

MITSUBISHI

Include in ##:

29405-00042

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29405-00042

ME304302

PUMP ASSY, SUPPLY

Information:

The following charts give general torques for bolts, nuts and taperlock studs of SAE Grade 5 or better quality.

Torques for Bolts and Nuts With Standard Threads

Torques for Taperlock Studs

Use these standard torque values for all fasteners unless otherwise specified in this publication or in the Service Manual.Torque for Metric Fasteners

Be very careful never to mix metric with customary (standard) fasteners. Mismatched or incorrect fasteners will cause engine damage or malfunction and may even result in personal injury.Original fasteners removed from the engine should be saved for reassembly whenever possible. If new fasteners are needed, they must be of the same size and grade as the ones that are being replaced.The material strength identification is usually shown on the bolt head by numbers (8.8, 10.9, etc.). The following chart gives general torques for bolts and nuts with Grade 8.8.

This product uses 10.9 Grade metric fasteners. Use these standard torque values unless otherwise specified in this publication.Torques for 10.9 Grade Bolts and Nuts with Metric Threads

Torque for Standard Hose Clamps-Worm Drive Band Type

The following chart gives the torques for initial installation of hose clamps on new hose and for reassembly or tightening of hose clamps on existing hose.

Torque for Constant Torque Hose Clamps

A constant torque hose clamp can be used in place of any standard hose clamp. Make sure the constant torque hose clamp is the same size as the standard clamp.Due to extreme temperature changes, hose will heat set. Heat setting causes hose clamps to loosen. Loose hose clamps can result in leaks. There have been reports of component failures caused by hose clamps loosening. The new, constant torque hose clamp will help prevent these failures.Installation

Each installation application can be different depending on the type of hose, fitting material and anticipated expansion or contraction of the hose and fittings. A torque wrench should be used for proper installation ofthe new, constant torque hose clamps. Constant torque hose clamps should be installed as follows:To allow for maximum expansion, install clamps at 50 lb in (5.7 N m).To allow for equal expansion and contraction, install clamps at 90 lb in (10.2 N m).To allow for maximum contraction, install clamps at 125 lb in (14.1 N m).