Rating:

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

HP3 Fuel Injection Pump for Hino J08E J09C 7.7L Engine 500 Series Ranger ND NE NJ NV 2005-294050-0019 22100-E0273

KoovDem Part Number: 294050-0019, 22100-E0273. || Compatible Model: For Hino J08E J09C 7.7L Engine 500 Series Ranger ND NE NJ NV 2005-. || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

KoovDem Part Number: 294050-0019, 22100-E0273. || Compatible Model: For Hino J08E J09C 7.7L Engine 500 Series Ranger ND NE NJ NV 2005-. || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

Aftermarket Injection Pump Plunger 294090-0660 294090-1350 Fit Intended For HP4 Pump 294050-0019 294050-0030 294050-0320 294050-0530 294050-0650

Generic

Generic

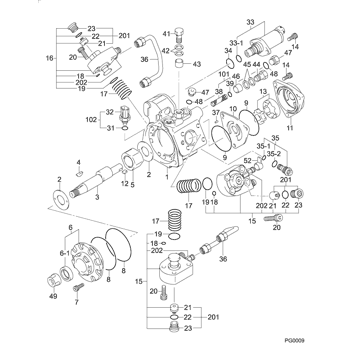

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29405-00019

PUMP ASSY, SUPPLY

HP4

1006-

22100-E0273

HINO

Include in ##:

29405-00019

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29405-00019

22100-E027

PUMP ASSY, SUPPLY

Information:

General Hazard Information

Attach a DO NOT OPERATE or similar warning tag to start switch or controls before performing maintenance or repairing the engine. These tags, SEHS7332, are available from your Caterpillar dealer. When appropriate, attach tags at the engine and pilot position, and disconnect starting controls. DO NOT ALLOW UNAUTHORIZED PERSONNEL ON OR AROUND THE ENGINE WHEN IT IS BEING SERVICED.* Wear a hard hat, protective glasses, hearing protection and other protective equipment as required by job conditions.* Do not wear loose clothing or jewelry that can catch on controls or other parts of the engine.* Make certain all protective guards and covers are secured in place.* Use all cleaning solutions with care.* Never put maintenance fluids into glass containers since glass containers can break.* Report all needed repairs.* Stop the engine.* Ensure the protective locks or controls are in the applied position.* Disconnect the batteries whenever performing any maintenance or before servicing the electrical system. If the engine has electric starting motors, disconnect and tape the battery ground leads to prevent accidental starting.* Lock out all electrical panels associated with the engine being serviced.* Do not attempt any repairs or adjustments to the engine or driven equipment while it is running.* Do not attempt repairs you do not understand. Use proper tools; replace or repair broken or damaged equipment.* When starting an engine after repairs have been made to the fuel system or governor, make provisions for shutting off the engine's intake air and/or fuel supply (to stop the engine), in case there is an overspeed on start-up.* Start the engine only from the pilot house. Never short across the starting motor terminals or the batteries as this could bypass the engine neutral-start system as well as damage the electrical system.Pressure Air and Water

Pressure air can cause personal injury. When using pressure air (maximum air pressure must be below 200 kPa [30 psi] for cleaning purposes) wear a protective face shield, protective clothing and protective shoes.Wear eye protection at all times when cleaning the cooling system. Pressurized water could cause debris and/or hot water to be blown and result in personal injury.Fluid Penetration

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury or possible death. If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Lines, Tubes and Hoses

Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommended torque. Repair any loose or damaged fuel and oil lines, tubes and hoses. Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses. Leaks can cause fires.* End fittings damaged, leaking or displaced.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in

Attach a DO NOT OPERATE or similar warning tag to start switch or controls before performing maintenance or repairing the engine. These tags, SEHS7332, are available from your Caterpillar dealer. When appropriate, attach tags at the engine and pilot position, and disconnect starting controls. DO NOT ALLOW UNAUTHORIZED PERSONNEL ON OR AROUND THE ENGINE WHEN IT IS BEING SERVICED.* Wear a hard hat, protective glasses, hearing protection and other protective equipment as required by job conditions.* Do not wear loose clothing or jewelry that can catch on controls or other parts of the engine.* Make certain all protective guards and covers are secured in place.* Use all cleaning solutions with care.* Never put maintenance fluids into glass containers since glass containers can break.* Report all needed repairs.* Stop the engine.* Ensure the protective locks or controls are in the applied position.* Disconnect the batteries whenever performing any maintenance or before servicing the electrical system. If the engine has electric starting motors, disconnect and tape the battery ground leads to prevent accidental starting.* Lock out all electrical panels associated with the engine being serviced.* Do not attempt any repairs or adjustments to the engine or driven equipment while it is running.* Do not attempt repairs you do not understand. Use proper tools; replace or repair broken or damaged equipment.* When starting an engine after repairs have been made to the fuel system or governor, make provisions for shutting off the engine's intake air and/or fuel supply (to stop the engine), in case there is an overspeed on start-up.* Start the engine only from the pilot house. Never short across the starting motor terminals or the batteries as this could bypass the engine neutral-start system as well as damage the electrical system.Pressure Air and Water

Pressure air can cause personal injury. When using pressure air (maximum air pressure must be below 200 kPa [30 psi] for cleaning purposes) wear a protective face shield, protective clothing and protective shoes.Wear eye protection at all times when cleaning the cooling system. Pressurized water could cause debris and/or hot water to be blown and result in personal injury.Fluid Penetration

Always use a board or cardboard when checking for a leak. Escaping fluid under pressure, even a pin-hole size leak, can penetrate body tissue, causing serious injury or possible death. If fluid is injected into your skin, it must be treated by a doctor familiar with this type of injury immediately.Lines, Tubes and Hoses

Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommended torque. Repair any loose or damaged fuel and oil lines, tubes and hoses. Do not bend or strike high pressure lines. Do not install bent or damaged lines, tubes or hoses. Leaks can cause fires.* End fittings damaged, leaking or displaced.* Outer covering chafed or cut and wire reinforcing exposed.* Outer covering ballooning locally.* Evidence of kinking or crushing of the flexible part of the hose.* Armoring embedded in