Rating:

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

TRUCK A2

Engine

A2

Serial start-end

1408-

Info

Injector Nozzle

Product

Fuel Injection Pump

Vehicle engine

TRUCK A2

Engine

A2

Serial start-end

1408-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$2,385.90

08 Mar 2025

0.1102[0.05] pounds

CN: ZhiFengDian shop

Diesel Fuel Pump Compatible For HYUNDAI D4CB 2.5L EURO 6 294000-2062 294000-2061 33100-4A900 294000-2060 Fuel Injection Pump

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Pump Compatible For HYUNDAI D4CB 2.5L EURO 6 294000-2062 294000-2061 33100-4A900 294000-2060 Fuel Injection Pump

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Pump Compatible For HYUNDAI D4CB 2.5L EURO 6 294000-2062 294000-2061 33100-4A900 294000-2060 Fuel Injection Pump

$907.83

08 Mar 2025

0.1102[0.05] pounds

CN: yinmeide shop

Common Rail Fuel Injection Pump 294000-2060 294000-2061 294000-2062 33100-4A900 331004A900 Compatible For Hyundai D4CBEURO 6 Engine

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || Common Rail Fuel Injection Pump 294000-2060 294000-2061 294000-2062 33100-4A900 331004A900 Compatible For Hyundai D4CBEURO 6 Engine

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || Common Rail Fuel Injection Pump 294000-2060 294000-2061 294000-2062 33100-4A900 331004A900 Compatible For Hyundai D4CBEURO 6 Engine

$920.70

08 Mar 2025

0.1102[0.05] Pounds

CN: fanhuan shop

Common Rail Fuel Injection Pump 294000-2060 294000-2061 294000-2062 33100-4A900 331004A900 Compatible For Hyundai D4CBEURO 6 Engine

VXRWKZEO Common Rail Fuel Injection Pump 294000-2060 294000-2061 294000-2062 33100-4A900 331004A900 Compatible For Hyundai D4CBEURO 6 Engine || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

VXRWKZEO Common Rail Fuel Injection Pump 294000-2060 294000-2061 294000-2062 33100-4A900 331004A900 Compatible For Hyundai D4CBEURO 6 Engine || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

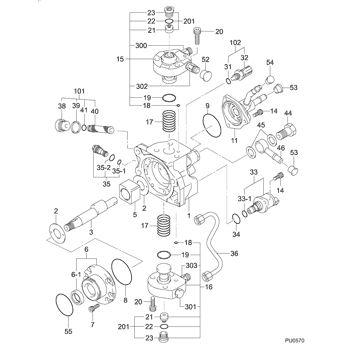

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

29400-02060

PUMP ASSY, SUPPLY

2940002060

331004A900

HYN

PUMP ASSY, SUPPLY

Information:

Start By:a. remove oil pan 1. Remove bolts (1) that hold main bearing cap (2) in place. Remove main cap (2).2. Remove the bearing half from the cap.

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both the crankshaft and cylinder block.

3. Remove the upper half of main bearings (3) as follows: a. Turn the crankshaft until tool (A) can be installed in the crankshaft journal. Install tool (A).b. Turn the crankshaft in the direction which will push the upper main bearing out, tab end first.c. Check the condition of the bearings. See "Guideline For Reusable Parts", "Main And Connecting Rod Bearings", Form No. SEBF8009 and SEBD0531. The following steps are for the installation of the crankshaft main bearings. Put clean engine oil on the main bearings for the assembly. Also, be sure the tabs on the back side of the main bearings fit in the grooves of the main bearings caps and cylinder block.

Ensure that the bearings are installed in the correct locations. Two different part numbers are used in the quantities of three and four. The part number having the quantity of four is to be installed on crankshaft main bearings 2, 3, 5 and 6. The part number having the quantity of three is to be installed on crankshaft bearing 1, 4 and 7.

4. Clean the surfaces in the cylinder block for the main bearings. Use tool (A), and install new upper halves of main bearings (bearings with the oil hole) in the cylinder block. Do not put oil on the back of the bearing.5. Clean the mating surface of the main bearing caps for the main bearings. Install the new lower halves of the main bearings in the main caps. Do not put oil on the back of the bearing.

Main bearing caps should be installed with the part number towards the right side. Caps are to be identified by stamped numbers 1 thru 7 located on the bottom unmachined surface.

6. Put main bearing caps (2) in position on the cylinder block. put clean engine oil or molylube on the bolt threads and the washer face; then install the bolts. Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).7. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example8. Check the end play of the crankshaft with a dial indicator and magnetic base. The end play must be 0.10 to 0.50 mm (.004 to .020 in). The

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both the crankshaft and cylinder block.

3. Remove the upper half of main bearings (3) as follows: a. Turn the crankshaft until tool (A) can be installed in the crankshaft journal. Install tool (A).b. Turn the crankshaft in the direction which will push the upper main bearing out, tab end first.c. Check the condition of the bearings. See "Guideline For Reusable Parts", "Main And Connecting Rod Bearings", Form No. SEBF8009 and SEBD0531. The following steps are for the installation of the crankshaft main bearings. Put clean engine oil on the main bearings for the assembly. Also, be sure the tabs on the back side of the main bearings fit in the grooves of the main bearings caps and cylinder block.

Ensure that the bearings are installed in the correct locations. Two different part numbers are used in the quantities of three and four. The part number having the quantity of four is to be installed on crankshaft main bearings 2, 3, 5 and 6. The part number having the quantity of three is to be installed on crankshaft bearing 1, 4 and 7.

4. Clean the surfaces in the cylinder block for the main bearings. Use tool (A), and install new upper halves of main bearings (bearings with the oil hole) in the cylinder block. Do not put oil on the back of the bearing.5. Clean the mating surface of the main bearing caps for the main bearings. Install the new lower halves of the main bearings in the main caps. Do not put oil on the back of the bearing.

Main bearing caps should be installed with the part number towards the right side. Caps are to be identified by stamped numbers 1 thru 7 located on the bottom unmachined surface.

6. Put main bearing caps (2) in position on the cylinder block. put clean engine oil or molylube on the bolt threads and the washer face; then install the bolts. Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).7. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example8. Check the end play of the crankshaft with a dial indicator and magnetic base. The end play must be 0.10 to 0.50 mm (.004 to .020 in). The