Rating:

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

TRUCK 4B3.9

Engine

4B3.9

Serial start-end

1110-

Info

Injector Nozzle

DCEC

PUMP ASSY, SUPPLY

HT

- * DMCF DENSO PRODUCTION CW294000-169#

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 5284018 for Cummins Engine ISBE3.9 ISBE5.9L

FGNTWP Part Number:294000-1690, 294000-1691, 294000-1692, 2940001690, 2940001691, 2940001692, 5284018 || Applications:Fit For Hyundai Forklift:35/40/45D/50DA-9, 35D-9, 35DA-9, 40D-9, 40DA-9, 45D-9, 45DA-9, 50D-9, 50DA-9

FGNTWP Part Number:294000-1690, 294000-1691, 294000-1692, 2940001690, 2940001691, 2940001692, 5284018 || Applications:Fit For Hyundai Forklift:35/40/45D/50DA-9, 35D-9, 35DA-9, 40D-9, 40DA-9, 45D-9, 45DA-9, 50D-9, 50DA-9

$981.68

20 Mar 2025

0.1102[0.05] pounds

CN: TWO-09

High Pressure Diesel Injector Pump Diesel Fuel Pump Assembly, Compatible With DCEC Truck 294000-1691 294000-1690 5284018

CHENUXO High Pressure Diesel Injector Pump Diesel Fuel Pump Assembly , Compatible With DCEC Truck 294000-1691 294000-1690 5284018 || Stable fuel supply: steadily extract fuel and deliver it at a certain pressure and flow rate to ensure the normal operation of the engine. || Pressure regulation: Equipped with a pressure regulator, it can automatically adjust the fuel pressure according to changes in working conditions. || Filtering impurities: It can effectively filter impurities in fuel and maintain engine and fuel system components. || Quick response: It has the ability to start and respond quickly, and can quickly establish stable fuel pressure.

CHENUXO High Pressure Diesel Injector Pump Diesel Fuel Pump Assembly , Compatible With DCEC Truck 294000-1691 294000-1690 5284018 || Stable fuel supply: steadily extract fuel and deliver it at a certain pressure and flow rate to ensure the normal operation of the engine. || Pressure regulation: Equipped with a pressure regulator, it can automatically adjust the fuel pressure according to changes in working conditions. || Filtering impurities: It can effectively filter impurities in fuel and maintain engine and fuel system components. || Quick response: It has the ability to start and respond quickly, and can quickly establish stable fuel pressure.

High Pressure Diesel Injector Pump Diesel Fuel Pump Assembly 294000-1691 294000-1690 Compatible With DCEC Truck 5284018

HXYAIEOGD Ensure the continuous and stable operation of the engine. || The installation procedure is simple. || Ensure OE number before placing order. || The warranty period is 12 months. || 1 piece jet pump

HXYAIEOGD Ensure the continuous and stable operation of the engine. || The installation procedure is simple. || Ensure OE number before placing order. || The warranty period is 12 months. || 1 piece jet pump

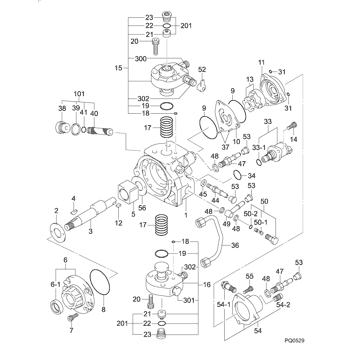

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29400-01690

PUMP ASSY, SUPPLY

HP3 *

Include in ##:

29400-01690

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29400-01690

DCEC

PUMP ASSY, SUPPLY

Information:

Start By:a. remove timing gear cover 1. Remove bolt (1) and washer that fastens the weight assembly (2).

Weight assembly must have support during removal to prevent damage to components.

2. Install tooling (A) and remove the weight assembly.Install Automatic Timing Advance Unit

1. Install washer and bolt (1). With the fuel pump housing cover removed, turn the fuel pump camshaft in the direction of engine rotation until tool (A) can be installed in the notch of the camshaft. 2. To time the fuel injection pump to the engine with the front timing cover removed, follow Steps 3 and 4. With the timing cover installed, see Steps 6 and 7. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of crankshaft rotation is given.3. Turn the crankshaft counterclockwise until the "C" on the crankshaft and camshaft and camshaft gears are in alignment. 4. Remove the plug and install tool (B) in the flywheel housing.5. To find top center compression stroke for No. 1 piston, turn the flywheel clockwise (opposite of engine rotation) approximately 30°. This procedure is to remove all end play from timing gears.6. Turn the flywheel counterclockwise (direction of engine rotation) until tool (B) can be installed in the flywheel. The piston is at top center. If you go past the bolt hole you must start over again. To see if the No. 1 piston is on the compression stroke, remove the breather assembly from the valve cover and look at the valves of the No. 1 cylinder. The valves will be closed if No. 1 cylinder is on the compression stroke. You must be able to move the rocker arms up and down with your hand.7. If NO. 1 piston is not on the compression stroke, remove tooling (B) and turn the flywheel 360° counterclockwise. Install tooling (B). The No. 1 piston is now at top center on the compression stroke.8. With tooling (A) and (B) installed in position, install the timing advance weight assembly on the fuel pump camshaft. 9. Install tooling (C) on the weight assembly. While a constant torque on drive gear on 68 N m (50 lb ft) is held, tighten the bolt that fastens the weight assembly to fuel pump camshaft to a torque of 270 25 N m (200 18 lb ft).10. Remove tooling (A), (B) and (C).End By:a. install timing gear coverDisassemble And Assemble Automatic Timing Unit

Start By:a. remove automatic timing advance unit

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove two screws (1) and plate (2).

The weights are held on position with two springs for each weight under compression. Carefully remove weights and springs to prevent possible injury.

2. Remove springs (4) and (5), weight (3) and slide (6) from each side of assembly. 3. If necessary, remove gear (7). Remove seals (11) and (10). The following steps

Weight assembly must have support during removal to prevent damage to components.

2. Install tooling (A) and remove the weight assembly.Install Automatic Timing Advance Unit

1. Install washer and bolt (1). With the fuel pump housing cover removed, turn the fuel pump camshaft in the direction of engine rotation until tool (A) can be installed in the notch of the camshaft. 2. To time the fuel injection pump to the engine with the front timing cover removed, follow Steps 3 and 4. With the timing cover installed, see Steps 6 and 7. No. 1 piston at top center (TC) on the compression stroke is the starting point for all timing procedures. The engine is seen from the flywheel end when direction of crankshaft rotation is given.3. Turn the crankshaft counterclockwise until the "C" on the crankshaft and camshaft and camshaft gears are in alignment. 4. Remove the plug and install tool (B) in the flywheel housing.5. To find top center compression stroke for No. 1 piston, turn the flywheel clockwise (opposite of engine rotation) approximately 30°. This procedure is to remove all end play from timing gears.6. Turn the flywheel counterclockwise (direction of engine rotation) until tool (B) can be installed in the flywheel. The piston is at top center. If you go past the bolt hole you must start over again. To see if the No. 1 piston is on the compression stroke, remove the breather assembly from the valve cover and look at the valves of the No. 1 cylinder. The valves will be closed if No. 1 cylinder is on the compression stroke. You must be able to move the rocker arms up and down with your hand.7. If NO. 1 piston is not on the compression stroke, remove tooling (B) and turn the flywheel 360° counterclockwise. Install tooling (B). The No. 1 piston is now at top center on the compression stroke.8. With tooling (A) and (B) installed in position, install the timing advance weight assembly on the fuel pump camshaft. 9. Install tooling (C) on the weight assembly. While a constant torque on drive gear on 68 N m (50 lb ft) is held, tighten the bolt that fastens the weight assembly to fuel pump camshaft to a torque of 270 25 N m (200 18 lb ft).10. Remove tooling (A), (B) and (C).End By:a. install timing gear coverDisassemble And Assemble Automatic Timing Unit

Start By:a. remove automatic timing advance unit

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove two screws (1) and plate (2).

The weights are held on position with two springs for each weight under compression. Carefully remove weights and springs to prevent possible injury.

2. Remove springs (4) and (5), weight (3) and slide (6) from each side of assembly. 3. If necessary, remove gear (7). Remove seals (11) and (10). The following steps