Rating:

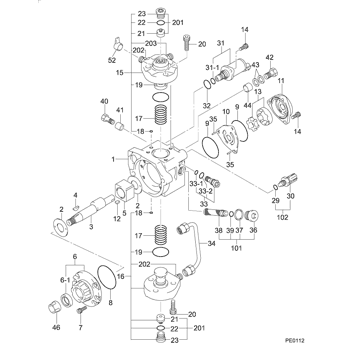

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

TRUCK J05D

Engine

J05D

Serial start-end

0312-

Info

Injector Nozzle

HINO

PUMP ASSY, SUPPLY

DA

- THIS CAN BE USED IN PLACE OF 294000-025# AS A SUPPLY.

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$595.90

19 Sep 2024

CN: SINOCMP Excavator Pa

SINOCMP 22100-E0333 294000-1650 294000-1653 Fuel Injection Pump for Hino J05D Engine

SINOCMP 【Accurate】installation and use our excavator parts. Please find the suitable product based on the old part number and machine model. || 【Scientific】products pass professional testing and inspection. Not sure what the construction machinery product will do? The adaptable products, safe using operation and easy installation. || 【Use】construction machinery product must be in accordance with operating procedures to avoid accidents. We will provide matching product usage guidance and professional product operation suggestions. || 【Key】construction machinery equipment meaning of existence? It is to bring convenience to life. In order to avoid the trouble of frequent replacement, strictly require product quality and improve service life.

SINOCMP 【Accurate】installation and use our excavator parts. Please find the suitable product based on the old part number and machine model. || 【Scientific】products pass professional testing and inspection. Not sure what the construction machinery product will do? The adaptable products, safe using operation and easy installation. || 【Use】construction machinery product must be in accordance with operating procedures to avoid accidents. We will provide matching product usage guidance and professional product operation suggestions. || 【Key】construction machinery equipment meaning of existence? It is to bring convenience to life. In order to avoid the trouble of frequent replacement, strictly require product quality and improve service life.

$593.69

19 Sep 2024

CN: QYWD

294000-1650 294000-1653 22100-E0333 Fuel Injection Pump for 2006 Hino J05D Engine

TUWODE Part Numbers: 22100-E0333 294000-1653 294000-1650 || Part Name: J05D High Pressure Fuel Pump || Application: for Hino J05D Engine || Reduced emissions: Better fuel management reduces unburned fuel and harmful emissions, making the engine more environmentally friendly. || Double-check the product picture and part number to make sure it's the item you're looking for and avoid buying the wrong one.

TUWODE Part Numbers: 22100-E0333 294000-1653 294000-1650 || Part Name: J05D High Pressure Fuel Pump || Application: for Hino J05D Engine || Reduced emissions: Better fuel management reduces unburned fuel and harmful emissions, making the engine more environmentally friendly. || Double-check the product picture and part number to make sure it's the item you're looking for and avoid buying the wrong one.

$665.00

19 Sep 2024

CN: cxemsetix

cxemsetix Fuel Injection Pump 22100-E0333 294000-1650 2940001650 22100E0333 Compatible with 2006 Hino 185 Truck J05D Engine

cxemsetix Part Number:294000-1650 22100-E0333 2940001650 22100E0333 || Application: Compatible with 2006 Hino 185 Truck J05D Engine || Fuel Type: Diesel || Warranty:3 months || Attention: If you have any questions or any questions that need to be answered by us before placing your order you can always consult us and we will patiently solve them for you. Because of the different time zone please give us some time all the emails will be answered within 24 hours .If there are any problems after receiving the goods please feel free to communicate with us and we will give you a satisfactory answer.The customer's reassurance is our happiness.

cxemsetix Part Number:294000-1650 22100-E0333 2940001650 22100E0333 || Application: Compatible with 2006 Hino 185 Truck J05D Engine || Fuel Type: Diesel || Warranty:3 months || Attention: If you have any questions or any questions that need to be answered by us before placing your order you can always consult us and we will patiently solve them for you. Because of the different time zone please give us some time all the emails will be answered within 24 hours .If there are any problems after receiving the goods please feel free to communicate with us and we will give you a satisfactory answer.The customer's reassurance is our happiness.

You can buy:

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

29400-01650

HINO

PUMP ASSY, SUPPLY

2940001650

22100-E0333

HINO

PUMP ASSY, SUPPLY

Information:

Start By:a. remove cylinder head assemblyb. remove oil panc. remove piston cooling jets 1. Remove two rod cap bolts (1) from each rod. Remove rod caps (2).2. Using a soft jawed hammer, tap rod (3) away from the crankshaft. Remove bearing half (4).

When removing the cylinder pack, watch the rod, and prevent it from catching on the bore in the cylinder block as it comes out.

3. Install tooling (A), and remove cylinder pack (5). 4. Remove cylinder liner seal (6) at the base of the spacer block.5. Remove the remainder of tooling (A) from cylinder pack (5). 6. Remove the rod and piston from the cylinder liner. Remove seal (7) from the cylinder liner. The following steps are for the installation of the cylinder pack.7. Install a new cylinder liner seal (6) in the base of the spacer block. Lubricate the seal with clean engine oil. Some engines use pistons which have the word "FRONT" stamped on the crown of the piston. Be sure the word "FRONT" is toward the front of the engine when the piston is installed. The etched number on the connecting rod must be on the right side and must be installed in the corresponding cylinder. 9U-5839 Liquid Gasket Material is applied to the cylinder liners in the area shown in the illustration. The liquid gasket material helps prevent oil leaks from between the cylinder block and spacer block. DO NOT apply any 9U-5839 Liquid Gasket Material between the engine spacer block and the cylinder block surfaces. Using excessive amounts of liquid gasket material on the liner flange seat can cause oil leaks due to distortion of the O-ring seals between the spacer block and cylinder block.8. Install a new seal (7) on the cylinder liner.9. Lubricate the lower portion of the cylinder liner with clean engine oil. Be sure the corresponding crankshaft throw is at bottom center. Position cylinder pack (5), and guide rod (3) into place. Use tooling (B), and press cylinder pack (5) into place. Refer to the "Systems Operation Testing And Adjusting" module, Form No. SENR5561, for checking Cylinder Liner Projection.10. With rod (3) in this position, install the upper half of rod bearing (4). Be sure the bearing tab properly engages with the slot in the connecting rod. Lubricate the bearing surface with clean engine oil. Tap the piston down with a soft faced hammer until the rod and bearing contacts the crankshaft.11. With rod cap bearing in place and lubricated, install rod cap (2). Lubricate rod bolts (1) with 2P2506 Thread Lubricant. Install rod bolts (1), and tighten them to a torque of 130 7 N m (95 5 lb ft). Mark each bolt head, and tighten each bolt an additional 1/6 60 5 ( turn).End By:a. install piston cooling jetsb. install oil panc. install cylinder head assembly

When removing the cylinder pack, watch the rod, and prevent it from catching on the bore in the cylinder block as it comes out.

3. Install tooling (A), and remove cylinder pack (5). 4. Remove cylinder liner seal (6) at the base of the spacer block.5. Remove the remainder of tooling (A) from cylinder pack (5). 6. Remove the rod and piston from the cylinder liner. Remove seal (7) from the cylinder liner. The following steps are for the installation of the cylinder pack.7. Install a new cylinder liner seal (6) in the base of the spacer block. Lubricate the seal with clean engine oil. Some engines use pistons which have the word "FRONT" stamped on the crown of the piston. Be sure the word "FRONT" is toward the front of the engine when the piston is installed. The etched number on the connecting rod must be on the right side and must be installed in the corresponding cylinder. 9U-5839 Liquid Gasket Material is applied to the cylinder liners in the area shown in the illustration. The liquid gasket material helps prevent oil leaks from between the cylinder block and spacer block. DO NOT apply any 9U-5839 Liquid Gasket Material between the engine spacer block and the cylinder block surfaces. Using excessive amounts of liquid gasket material on the liner flange seat can cause oil leaks due to distortion of the O-ring seals between the spacer block and cylinder block.8. Install a new seal (7) on the cylinder liner.9. Lubricate the lower portion of the cylinder liner with clean engine oil. Be sure the corresponding crankshaft throw is at bottom center. Position cylinder pack (5), and guide rod (3) into place. Use tooling (B), and press cylinder pack (5) into place. Refer to the "Systems Operation Testing And Adjusting" module, Form No. SENR5561, for checking Cylinder Liner Projection.10. With rod (3) in this position, install the upper half of rod bearing (4). Be sure the bearing tab properly engages with the slot in the connecting rod. Lubricate the bearing surface with clean engine oil. Tap the piston down with a soft faced hammer until the rod and bearing contacts the crankshaft.11. With rod cap bearing in place and lubricated, install rod cap (2). Lubricate rod bolts (1) with 2P2506 Thread Lubricant. Install rod bolts (1), and tighten them to a torque of 130 7 N m (95 5 lb ft). Mark each bolt head, and tighten each bolt an additional 1/6 60 5 ( turn).End By:a. install piston cooling jetsb. install oil panc. install cylinder head assembly