Rating:

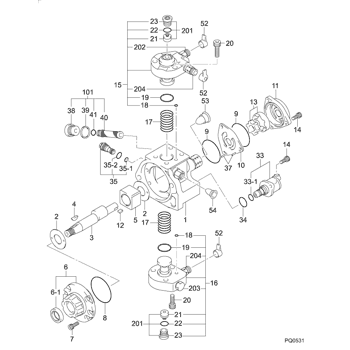

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL 350S

Engine

350S

Serial start-end

1103-

Info

Injector Nozzle

JOHN DEERE

PUMP ASSY, SUPPLY

NB

- * DMHU PRODUCTION HU294000-154*

- # DNJP PRODUCTION 294000-154*

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump RE543423 294000-1540 2940001540 Compatible For John Deere 4045 Engine 5085E 5090R 6130D 6140D 605K W155, W170

NYGDRCOT Manufacturing process: Using advanced manufacturing techniques and high-quality materials, it can work stably for a long time and is not prone to malfunctions. || Driving experience: Its noise is very low, providing you with a quiet and comfortable driving environment. Installation is also very convenient, you don't have to worry about any troubles during the installation process. || Functional testing: Its main function is to extract fuel from the fuel tank and deliver it to the engine's fuel injection system at a certain pressure. Its flow rate and pressure have been precisely designed and rigorously tested. || Quality assurance: It can effectively prevent fuel leakage and motor damage. Even in harsh working environments such as high temperature, high pressure, vibration, etc., it can maintain stable performance and extend its service life. || Fuel Injection Pump RE543423 294000-1540 2940001540 Compatible For John Deere 4045 Engine 5085E 5090R 6130D 6140D 605K W155, W170

NYGDRCOT Manufacturing process: Using advanced manufacturing techniques and high-quality materials, it can work stably for a long time and is not prone to malfunctions. || Driving experience: Its noise is very low, providing you with a quiet and comfortable driving environment. Installation is also very convenient, you don't have to worry about any troubles during the installation process. || Functional testing: Its main function is to extract fuel from the fuel tank and deliver it to the engine's fuel injection system at a certain pressure. Its flow rate and pressure have been precisely designed and rigorously tested. || Quality assurance: It can effectively prevent fuel leakage and motor damage. Even in harsh working environments such as high temperature, high pressure, vibration, etc., it can maintain stable performance and extend its service life. || Fuel Injection Pump RE543423 294000-1540 2940001540 Compatible For John Deere 4045 Engine 5085E 5090R 6130D 6140D 605K W155, W170

Fuel Injection Pump RE543423 294000-1540 2940001540 ,Compatible For John Deere 4045 Engine 5085E 5090R 6130D 6140D 605K W155, W170

Sdvbfjnm Precision-engineered to enhance the ,Compatible For your John Deere 4045 engine, ensuring optimal fuel delivery for maximum efficiency. || Direct replacement ,Compatible For OEM part numbers RE543423 and 294000-1540, guaranteeing a perfect fit and reliable operation. || Compatible with a variety of John Deere models including 5085E, 5090R, 6130D, 6140D, 605K, W155, and W170 for versatile application. || Constructed from high-quality materials for durability and long-lasting performance under demanding conditions. || Easy installation process, designed to minimize downtime and get your equipment back in operation quickly.

Sdvbfjnm Precision-engineered to enhance the ,Compatible For your John Deere 4045 engine, ensuring optimal fuel delivery for maximum efficiency. || Direct replacement ,Compatible For OEM part numbers RE543423 and 294000-1540, guaranteeing a perfect fit and reliable operation. || Compatible with a variety of John Deere models including 5085E, 5090R, 6130D, 6140D, 605K, W155, and W170 for versatile application. || Constructed from high-quality materials for durability and long-lasting performance under demanding conditions. || Easy installation process, designed to minimize downtime and get your equipment back in operation quickly.

Fuel Injection Pump ,Compatible For John Deere 4045 5085E 5090R 6130D 6140D 294000-1540 RE543423 2940001540

CHENEGWUU The noise generated during the working process is low, providing a quiet and comfortable driving environment for the driver || Low energy consumption design reduces the overall energy consumption of the car and improves fuel economy || Deliver fuel in an efficient manner to reduce energy consumption and improve fuel efficiency || Stable pressure to ensure the normal operation of the fuel injection system and improve engine operation stability || Fuel Injection Pump ,Compatible For John Deere 4045 5085E 5090R 6130D 6140D 294000-1540 RE543423 2940001540

CHENEGWUU The noise generated during the working process is low, providing a quiet and comfortable driving environment for the driver || Low energy consumption design reduces the overall energy consumption of the car and improves fuel economy || Deliver fuel in an efficient manner to reduce energy consumption and improve fuel efficiency || Stable pressure to ensure the normal operation of the fuel injection system and improve engine operation stability || Fuel Injection Pump ,Compatible For John Deere 4045 5085E 5090R 6130D 6140D 294000-1540 RE543423 2940001540

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

29400-01540

JOHN DEERE

PUMP ASSY, SUPPLY

Information:

1. Remove cylinder head assembly mounting bolts (1) and (2).

To prevent damage to the cylinder head assembly-to-spacer block dowels, keep the head assembly level during removal.

2. Fasten a hoist to the cylinder head assembly as shown. Lift the cylinder head assembly off of the spacer block. The approximate weight of the cylinder head is 236 kg (520 lb).3. Remove the cylinder head assembly gasket from the spacer block. The following steps are for the installation of the cylinder head assembly.4. Thoroughly clean the mating surfaces of the cylinder head assembly and the spacer block.5. Install the head gasket on the spacer block.6. Fasten a hoist to the cylinder head assembly. Position the cylinder head assembly on the dowels in the spacer block. Lower the cylinder head assembly onto the spacer block.7. Put clean engine oil on the threads of bolts (1) and (2) that hold the cylinder head assembly in position. Install bolts (1) and (2).

Cylinder Head Assembly Tightening Sequence8. Tighten cylinder head assembly mounting bolts (1) and (2) as follows:a. Put 2P2506 Thread Lubricant on the threads of bolts (1) and (2).b . Tighten bolts 1 through 26 in numerical sequence shown to a torque of 150 15 N m (110 11 lb ft).c. Tighten bolts 1 through 26 in numerical sequence shown to a torque of 275 15 N m (200 11 lb ft).d. Retorque bolts 1 through 26 in numerical sequence shown to 275 15 N m (200 11 lb ft).e. Tighten bolts 27 through 33 in numerical sequence shown to a torque of 25 7 N m (18 5 lb ft).End By:a. install valve cover baseb. install (EUI) fuel injectorsc. install rocker arm assemblies and push rodsd. install water outlet manifolde. install exhaust manifold

To prevent damage to the cylinder head assembly-to-spacer block dowels, keep the head assembly level during removal.

2. Fasten a hoist to the cylinder head assembly as shown. Lift the cylinder head assembly off of the spacer block. The approximate weight of the cylinder head is 236 kg (520 lb).3. Remove the cylinder head assembly gasket from the spacer block. The following steps are for the installation of the cylinder head assembly.4. Thoroughly clean the mating surfaces of the cylinder head assembly and the spacer block.5. Install the head gasket on the spacer block.6. Fasten a hoist to the cylinder head assembly. Position the cylinder head assembly on the dowels in the spacer block. Lower the cylinder head assembly onto the spacer block.7. Put clean engine oil on the threads of bolts (1) and (2) that hold the cylinder head assembly in position. Install bolts (1) and (2).

Cylinder Head Assembly Tightening Sequence8. Tighten cylinder head assembly mounting bolts (1) and (2) as follows:a. Put 2P2506 Thread Lubricant on the threads of bolts (1) and (2).b . Tighten bolts 1 through 26 in numerical sequence shown to a torque of 150 15 N m (110 11 lb ft).c. Tighten bolts 1 through 26 in numerical sequence shown to a torque of 275 15 N m (200 11 lb ft).d. Retorque bolts 1 through 26 in numerical sequence shown to 275 15 N m (200 11 lb ft).e. Tighten bolts 27 through 33 in numerical sequence shown to a torque of 25 7 N m (18 5 lb ft).End By:a. install valve cover baseb. install (EUI) fuel injectorsc. install rocker arm assemblies and push rodsd. install water outlet manifolde. install exhaust manifold