Rating:

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

DUTRO N04C

Engine

N04C

Serial start-end

1105-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Common Rail Fuel Injection Pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 22100-E0541

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Common Rail Fuel Injection Pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 22100-E0541

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Common Rail Fuel Injection Pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 22100-E0541

Diesel Fuel Injection Pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 Compatible For HINO N04C

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 Compatible For HINO N04C

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 Compatible For HINO N04C

HP3 Fuel Pump 294000-1441 294000-1440 For 22100-E0540-A Diesel Injection Pump 22100-E0540

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || HP3 Fuel Pump 294000-1441 294000-1440 For 22100-E0540-A Diesel Injection Pump 22100-E0540

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || HP3 Fuel Pump 294000-1441 294000-1440 For 22100-E0540-A Diesel Injection Pump 22100-E0540

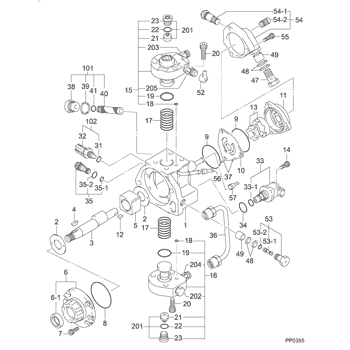

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29400-01440

PUMP ASSY, SUPPLY

HP3 #

22100-E0540-A

HINO

Include in ##:

29400-01440

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29400-01440

22100-E054

PUMP ASSY, SUPPLY

2940001440

22100-E0540-A

HINO

PUMP ASSY, SUPPLY

Information:

2. Remove bolts (1) from the adapter. Loosen turbocharger compressor housing clamp (2), and rotate turbocharger tube (3) out of the way of the aftercooler housing. 3. Put identification marks on the bolts which hold the aftercooler cover in position for installation purposes. Remove bolts (4) that hold the aftercooler cover to the aftercooler housing. Remove aftercooler cover (5). 4. Remove four bolts (6), elbow (7), the two adapters and pipe (8). 5. Remove four bolts (9), elbow (10) and two adapters (11). 6. Remove aftercooler core (12) from aftercooler housing (13). 7. Remove O-ring seals (14) and gaskets (15) if necessary.Install Aftercooler Core

1. Clean and inspect all parts. Make a replacement of all parts that are worn or damaged. Lubricate all O-ring seals with clean engine oil at assembly. 2. Install O-ring seals (1). Fasten gaskets (2) to both sides of the aftercooler core flange with 5H2471 Cement. 3. Put aftercooler core (3) in position in the aftercooler housing with the end that has the identification "Jacket Water, Fresh Air" toward the water inlet end of the aftercooler housing. 4. Install cover (4) on the aftercooler housing. Be sure to install the long bolts in the thru bolt holes.

To prevent damage to the aftercooler core, tighten the bolts that hold the aftercooler core before tightening the bolts that hold the adapters.

5. Tighten the aftercooler core cover bolts to a torque of 25 7 N m (18 5 lb.ft.). Tighten the bolts again after engine is operated to a torque of 25 7 N m (18 5 lb.ft.). 6. Install gasket (5) and adapter (6) on the aftercooler housing. 7. Install adapter (7) on adapter (6). 8. Put O-ring seals (8) on pipe (9), and install pipe (9) into elbow (10). 9. Install elbow (11) on pipe (9). Put gasket (12) in position between elbow (11) and adapter (7), and fasten the elbow to aftercooler housing with four bolts. 10. Install gasket (13) and adapter (14) on the aftercooler housing. 11. Install adapter (15) on adapter (14). 12. Put O-ring seal (16) in position on tube (17), and install elbow (18) on tube (17). Put gasket (19) in position between elbow (18) and adapter (15), and fasten the elbow to the aftercooler housing with four bolts. 13. Rotate turbocharger tube (20) into position. Place a gasket between the aftercooler housing and adapter, and install the four bolts and nuts that hold it.14. Tighten turbocharger clamp nut (21) to a torque of 18 3 N m (13 2 lb.ft.). Lightly hit all around the clamp with a soft faced hammer, and tighten the clamp nut again to the same torque value.15. Fill the engine with coolant to the correct level. See the Maintenance Guide.

1. Clean and inspect all parts. Make a replacement of all parts that are worn or damaged. Lubricate all O-ring seals with clean engine oil at assembly. 2. Install O-ring seals (1). Fasten gaskets (2) to both sides of the aftercooler core flange with 5H2471 Cement. 3. Put aftercooler core (3) in position in the aftercooler housing with the end that has the identification "Jacket Water, Fresh Air" toward the water inlet end of the aftercooler housing. 4. Install cover (4) on the aftercooler housing. Be sure to install the long bolts in the thru bolt holes.

To prevent damage to the aftercooler core, tighten the bolts that hold the aftercooler core before tightening the bolts that hold the adapters.

5. Tighten the aftercooler core cover bolts to a torque of 25 7 N m (18 5 lb.ft.). Tighten the bolts again after engine is operated to a torque of 25 7 N m (18 5 lb.ft.). 6. Install gasket (5) and adapter (6) on the aftercooler housing. 7. Install adapter (7) on adapter (6). 8. Put O-ring seals (8) on pipe (9), and install pipe (9) into elbow (10). 9. Install elbow (11) on pipe (9). Put gasket (12) in position between elbow (11) and adapter (7), and fasten the elbow to aftercooler housing with four bolts. 10. Install gasket (13) and adapter (14) on the aftercooler housing. 11. Install adapter (15) on adapter (14). 12. Put O-ring seal (16) in position on tube (17), and install elbow (18) on tube (17). Put gasket (19) in position between elbow (18) and adapter (15), and fasten the elbow to the aftercooler housing with four bolts. 13. Rotate turbocharger tube (20) into position. Place a gasket between the aftercooler housing and adapter, and install the four bolts and nuts that hold it.14. Tighten turbocharger clamp nut (21) to a torque of 18 3 N m (13 2 lb.ft.). Lightly hit all around the clamp with a soft faced hammer, and tighten the clamp nut again to the same torque value.15. Fill the engine with coolant to the correct level. See the Maintenance Guide.