Rating:

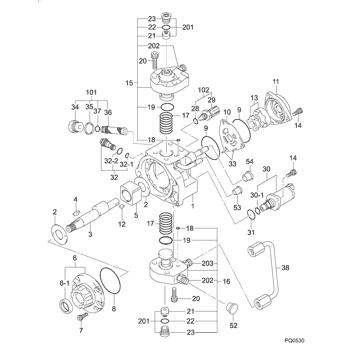

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL VISTA-E

Engine

VISTA-E

Serial start-end

1106-

Info

24V

Injector Nozzle

PERKINS

PUMP ASSY, SUPPLY

XU

- * DMHU DENSO PRODUCTION HU294000-139#

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29400-01390

PUMP ASSY, SUPPLY

HP3 *

Include in ##:

29400-01390

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29400-01390

PERKINS

PUMP ASSY, SUPPLY

2940001390

3559906

PERKINS

PUMP ASSY SUPPLY

Test Calibration Data:

02EN139000

3708364

02EN139000

3708364

Information:

Minor Operating Faults

To help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the Primary Engine Checks section.Fuel Ratio Control Out Of Adjustment Or Bad

Follow the procedure in the Testing and Adjusting section of this Service Manual.Check Engine Performance

Do a Power Analysis report (PAR), Level II, to check engine performance. See Special Instruction, Form No. SEHS8025 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant.Fuel Settings Not Correct

If the Power Analysis Report indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see Owner/Operator input section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.Bad Fuel Nozzle(s)

Remove the fuel nozzles and test as in the Testing and Adjusting section of this Service Manual.Recommended Procedure Without Chassis Dynamometer

Possible Causes/CorrectionsMinor Operating Faults

To help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the Primary Engine Checks section.Fuel Ratio Control Out Of Adjustment Or Bad

Follow the procedure in the Testing and Adjusting section of this Service Manual.Fuel Injection Timing Not Correct

Follow the procedures in the Testing and Adjusting section of this Service Manual.Check Engine Performance

Install the tooling and follow the procedure given in the Road Test section.Fuel Settings Not Correct

If the Road Test indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see Owner Operator Input section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.Any Further Diagnosis Must Be Done On A Chassis Dynamometer

If the fuel settings are correct and the above procedures have been followed without finding the problem a Power Analysis Report (PAR), Level II, must be done on the engine. See Special Instruction, Form Nos. SEHS8025 and SEHS7886 for the correct tools and procedures to use.

To help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the Primary Engine Checks section.Fuel Ratio Control Out Of Adjustment Or Bad

Follow the procedure in the Testing and Adjusting section of this Service Manual.Check Engine Performance

Do a Power Analysis report (PAR), Level II, to check engine performance. See Special Instruction, Form No. SEHS8025 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant.Fuel Settings Not Correct

If the Power Analysis Report indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see Owner/Operator input section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.Bad Fuel Nozzle(s)

Remove the fuel nozzles and test as in the Testing and Adjusting section of this Service Manual.Recommended Procedure Without Chassis Dynamometer

Possible Causes/CorrectionsMinor Operating Faults

To help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the Primary Engine Checks section.Fuel Ratio Control Out Of Adjustment Or Bad

Follow the procedure in the Testing and Adjusting section of this Service Manual.Fuel Injection Timing Not Correct

Follow the procedures in the Testing and Adjusting section of this Service Manual.Check Engine Performance

Install the tooling and follow the procedure given in the Road Test section.Fuel Settings Not Correct

If the Road Test indicates a problem, the governor fuel settings should be verified. See the Testing and Adjusting section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see Owner Operator Input section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.Any Further Diagnosis Must Be Done On A Chassis Dynamometer

If the fuel settings are correct and the above procedures have been followed without finding the problem a Power Analysis Report (PAR), Level II, must be done on the engine. See Special Instruction, Form Nos. SEHS8025 and SEHS7886 for the correct tools and procedures to use.