Rating:

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL S350

Engine

S350

Serial start-end

0709-

Info

Injector Nozzle

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL S350

Engine

S350

Serial start-end

1010-

Info

Injector Nozzle

JOHN DEERE

PUMP ASSY, SUPPLY

NB

- #..SWITCHED TO DMHU PRODUCTION FROM 1010

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$648.39

11 Nov 2024

CN: Zachager

Zachager 1PC Fuel Injection Pump 294000-0750 294000-0751 RE533507 for John Deere Engine S350

Zachager PART NUMBER: 294000-0750 294000-0751 RE533507 || APPLICATION: for John Deere Engine S350 || Fuel Injection Pump works absolutely well since every item we have executed a strict quality test prior shipping.Plug and play, easy to install, you could use it directly. || Please check the specification carefully to ensure you get what you want.Our products are made of High quality durability material and excellent crafts.Proper use of the product can make the product have a longer service life || Please rest assured to buy our products, we will deliver the products to you faster.

Zachager PART NUMBER: 294000-0750 294000-0751 RE533507 || APPLICATION: for John Deere Engine S350 || Fuel Injection Pump works absolutely well since every item we have executed a strict quality test prior shipping.Plug and play, easy to install, you could use it directly. || Please check the specification carefully to ensure you get what you want.Our products are made of High quality durability material and excellent crafts.Proper use of the product can make the product have a longer service life || Please rest assured to buy our products, we will deliver the products to you faster.

$58.99

15 Jan 2024

HK: STA Online

MagiDeal Fuel Pump Pressure Regulator Control Valve,294000-0503 294000-0501 for 294000-0654 294000-0750 Long Service Life, Easily Install,Premium

MagiDeal 【Part number】:294000-0654 294000-0662 294000-0690, 294000-0750, 294000-0560 294000-0581 294000-0621, 294000-0640, 294000-0501 294000-0502 294000-0503, 294000-0532, 294000-0404 294000-0412, 294000-0424, 294000-0237 294000-0334, 6C1Q-9H321-AB, 294009-0260, LR009837, 1514885 6C1Q-9358-AB, 294200-0360, 294200-0160 0160 0260 0360, 1920.QK 1920QK, 1920 QK 294009-0160, 9665523380 DCRS300260, 1497165 1386568, 1920.NL 1920NL 1920 NL, 9664613980 LR006866 6C1Q-9H321, 6C1Q9H321AA, 294200-0260. || 【High Quality Material】: The Fuel pump pressure regulator control valve is made of high quality stainless steel material, which is durable. || 【Easy to Install】: The fuel Pressure Regulator is easy and convenient to install, saving your energy and time. || 【Function】: The fuel Pressure Regulator Valve has oil resistance, wear resistance, stable performance, and high reliability. || 【Car Decoration】: Stylish and cool, full of color, enhances the decoration of the car and makes your car more fashionable.

MagiDeal 【Part number】:294000-0654 294000-0662 294000-0690, 294000-0750, 294000-0560 294000-0581 294000-0621, 294000-0640, 294000-0501 294000-0502 294000-0503, 294000-0532, 294000-0404 294000-0412, 294000-0424, 294000-0237 294000-0334, 6C1Q-9H321-AB, 294009-0260, LR009837, 1514885 6C1Q-9358-AB, 294200-0360, 294200-0160 0160 0260 0360, 1920.QK 1920QK, 1920 QK 294009-0160, 9665523380 DCRS300260, 1497165 1386568, 1920.NL 1920NL 1920 NL, 9664613980 LR006866 6C1Q-9H321, 6C1Q9H321AA, 294200-0260. || 【High Quality Material】: The Fuel pump pressure regulator control valve is made of high quality stainless steel material, which is durable. || 【Easy to Install】: The fuel Pressure Regulator is easy and convenient to install, saving your energy and time. || 【Function】: The fuel Pressure Regulator Valve has oil resistance, wear resistance, stable performance, and high reliability. || 【Car Decoration】: Stylish and cool, full of color, enhances the decoration of the car and makes your car more fashionable.

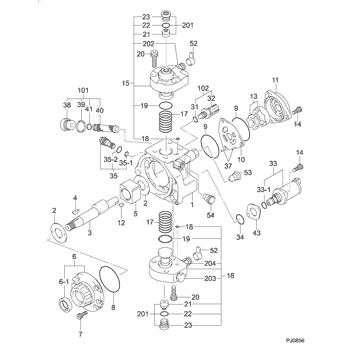

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29400-00750

PUMP ASSY, SUPPLY

HP3

-1006

Include in ##:

29400-00750

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29400-00750

JOHN DEERE

PUMP ASSY, SUPPLY

2940000750

RE533507

JOHN DEERE

PUMP ASSY SUPPLY

Test Calibration Data:

02EN075000

RE533507

02EN075000

RE533507

02EN075000

RE533507

Information:

REMOVING CONNECTING ROD BEARING CAP4. Push the piston and connecting rod upward until the piston rings clear the cylinder block. Remove the piston and connecting rod from the cylinder block.

REMOVING PISTON

Do not allow the connecting rods to hit the bottom edge of the cylinder bores or crankshaft journals when removing or installing. Check the lower portion of the bores for burrs or scratches. Use crocus cloth to remove any burrs or scratches from bottom edge of the bores.

5. Keep the connecting rod bearing cap with its respective connecting rod and piston.6. Repeat Steps 2 through 5 for the remaining pistons.Install Pistons

1. Rotate the crankshaft to position bearing journal of the piston to be installed.2. Lubricate the crankshaft bearing journal, bore in cylinder block, piston, rings, and connecting rod bearings with clean engine oil (SAE 30).3. Install a 1Y7426 Ring Compressor (3), or the 4S9450 Compressor (1) and the 4S9446 Clamp (2) from the 4S9458 Teflon Seal Tool Group, on the piston to compress the rings. Install the piston and connecting rod in cylinder bore with piston crater toward vee of engine. Guide the lower end of connecting rod over the crankshaft journal to prevent damage to the crankshaft.

INSTALLING PISTON

1. 4S9450 Compressor. 2. 4S9446 Clamp.

INSTALLING PISTON ALTERNATE METHOD

3. 1Y7426 Ring Compressor.4. Install the connecting rod cap to connecting rod so numbers correspond and both numbers appear on the same side. Lubricate bolt threads, seating faces of cap and nuts, install the retaining nuts and tighten to 30 3 lb. ft. (4.1 0.4 mkg). Mark cap and nut with matching marks. Tighten additional from mark 60° 5°.5. Repeat Steps 1 thru 4 for the remaining pistons.Disassemble Piston

PISTON ASSEMBLY1. Use ring expander (1) to remove rings.

REMOVING RINGS

1. 5F9059 Ring Expander.2. Remove snap ring (5) and push piston pin (2) out of piston (4) and connecting rod (3).

PISTON DISASSEMBLED

2. Piston pin. 3. Connecting rod. 4. Piston. 5. Snap ring.Assemble Piston

1. Install connecting rod into piston with boss on rod on same side as crater in piston crown.

CONNECTING ROD AND PISTON

CONNECTING ROD AND PISTON Installation of connecting rods WITHOUT BOSS on rod; Install connecting rod into piston with cylinder identification number (as marked on the lower end of the rod and on the cap) 180° opposite the crater in piston crown.2. Install piston pin and snap rings.3. Use the 8S2304 Piston Ring Groove Cleaner to clean the piston ring grooves before installing piston rings.4. Install oil ring spring (6) before installing oil ring.

8S2304 RING GROOVE CLEANER

INSTALLING OIL RING SPRING

6. Oil ring spring.5. Use a 5F9059 Ring Expander to install piston rings. Install compression ring with side marked "TOP" toward top of piston. Install oil ring with gap 180° from oil ring spring joint and approximately 120° from compression ring gap.