Rating:

Information pump assy, supply Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL S350

Engine

S350

Serial start-end

0512-

Info

294000-056_ can be used instead of 294000-039_.

Injector Nozzle

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL S350

Engine

S350

Serial start-end

0905-

Info

294000-056_ can be used instead of 294000-039_.

Injector Nozzle

JOHN DEERE

PUMP ASSY, SUPPLY

NB

- *1 294000-056# CAN BE USED INSTEAD OF 294000-039#

- #..SWITCHED TO DMHU PRODUCTION FROM 0905

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

294000-0059 RE507959 294000-0560 RE527528 294000-0050 294000-0051 Fuel Injection Pump for John Deere Engine 6045 4045 6068 Excavator 120D 130G Fuel Pump Replacement Parts

Yuubryczny Part Number: RE507959 294000-0059 294000-0560 RE527528 294000-0050 294000-0051 294000-0052 294000-0053 294000-0054 294000-0055 294000-0056 294000-0057 294000-0058 294000-0561 294000-0562 294000-0563 294000-0564 294000-0565 294000-0566 294000-0567 294000-0568 294000-0569 || Applications: Fuel Injection Pump Fit for John Deere Engine 6045 4045 6068, Excavator 120D 130G 160DLC 160GLC 180GLC 200DLC 210G 240DLC 250GLC 270DLC 290GLC, Grader Motor 670C 670D. || Ideal Replacement: Made with high-quality materials and precision-designed, suitable for specific vehicles. Professionally aged tested to ensure durability. High engine performance and quiet running with low fuel consumption and fewer emissions. || Easy to install: Quick and effortless installation through replacement. || Ensure Fitment: Please check the part number and vehicle model to ensure the product fits your needs.

Yuubryczny Part Number: RE507959 294000-0059 294000-0560 RE527528 294000-0050 294000-0051 294000-0052 294000-0053 294000-0054 294000-0055 294000-0056 294000-0057 294000-0058 294000-0561 294000-0562 294000-0563 294000-0564 294000-0565 294000-0566 294000-0567 294000-0568 294000-0569 || Applications: Fuel Injection Pump Fit for John Deere Engine 6045 4045 6068, Excavator 120D 130G 160DLC 160GLC 180GLC 200DLC 210G 240DLC 250GLC 270DLC 290GLC, Grader Motor 670C 670D. || Ideal Replacement: Made with high-quality materials and precision-designed, suitable for specific vehicles. Professionally aged tested to ensure durability. High engine performance and quiet running with low fuel consumption and fewer emissions. || Easy to install: Quick and effortless installation through replacement. || Ensure Fitment: Please check the part number and vehicle model to ensure the product fits your needs.

294000-0560 2940000560 Fuel Injection Pump Fits for JD Engine 6045 Excavator 120D 130G 160D 200D 210G 240D 290G E210LC E240LC E300LC Loader 210K 310K

ZJSYPXB ⚙️ Part Name ⚙️:Fuel Injection Pump || ⚙️ Part Number ⚙️:294000-0560 2940000560 || ⚙️ Application ⚙️:Compatible with JD Engine 6045 Excavator 120D 130G 160D 200D 210G 240D 290G E210LC E240LC E300LC Loader 210K 310K || ⚙️ Accurate ⚙️ -Install and use our accessories. Please find the right product according to the old part number and machine model, if you are not sure, please contact us in time, we are more than happy to provide services. || ⚙️ Reliable performance ⚙️ -Carefully designed and tested, with high reliability and stability, can maintain good working condition for a long time.

ZJSYPXB ⚙️ Part Name ⚙️:Fuel Injection Pump || ⚙️ Part Number ⚙️:294000-0560 2940000560 || ⚙️ Application ⚙️:Compatible with JD Engine 6045 Excavator 120D 130G 160D 200D 210G 240D 290G E210LC E240LC E300LC Loader 210K 310K || ⚙️ Accurate ⚙️ -Install and use our accessories. Please find the right product according to the old part number and machine model, if you are not sure, please contact us in time, we are more than happy to provide services. || ⚙️ Reliable performance ⚙️ -Carefully designed and tested, with high reliability and stability, can maintain good working condition for a long time.

$519.00

06 Nov 2024

CN: IMELBUFF Excavator P

IMELBUFF 294000-0560 RE527528 CR HP3 Fuel Injection Pump for John Deere 4045T 6068T Engine 160DLC 160GLC 200DLC 210G 410J 410K 310L 650J Excavator Loader

IMELBUFF 🚜Part Number: 294000-0560 RE527528 || 🚜Engine Model: for John Deere 4045T 6068T Engine || 🚜Application: for John Deere 210K 210LJ 310G 310J 310SJ 315SK 410G 410K 710K S550 T550 W540 450J 550H 120D 130G 160DLC 160GLC 180GLC 210G 210GLC || 🚜Warm Tips: Please check your part numbers before placing an order. If you are not sure, you can send us your engine model or fuel pump part number || 🚜Service: 5-months warranty and 24 hour support for customer service. Please feel free to contact us by email if you have any question with the product

IMELBUFF 🚜Part Number: 294000-0560 RE527528 || 🚜Engine Model: for John Deere 4045T 6068T Engine || 🚜Application: for John Deere 210K 210LJ 310G 310J 310SJ 315SK 410G 410K 710K S550 T550 W540 450J 550H 120D 130G 160DLC 160GLC 180GLC 210G 210GLC || 🚜Warm Tips: Please check your part numbers before placing an order. If you are not sure, you can send us your engine model or fuel pump part number || 🚜Service: 5-months warranty and 24 hour support for customer service. Please feel free to contact us by email if you have any question with the product

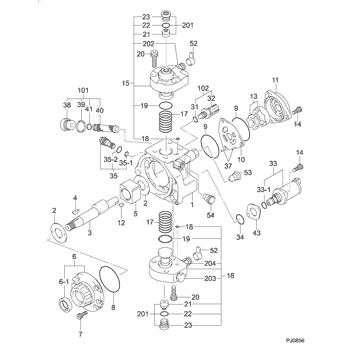

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

29400-00560

JOHN DEERE

PUMP ASSY, SUPPLY

2940000560

RE527528

JOHN DEERE

PUMP ASSY SUPPLY

Test Calibration Data:

02EN056000

RE527528

02EN056000

RE527528

02EN056000

RE527528

02EN056000

RE527528

02EN056000

RE527528

Information:

Marks For Tightening Connecting Rod Bolts-7E5996 Connecting Rod Assembly(1) Bore in connecting rod for piston pin bearing ... 55.436 0.013 mm (2.1825 .0005 in) The connecting rod must be heated for installation of piston pin bearing. Do not use a torch.(2) Distance rod may be heated to 175 to 260°C (347 to 500°F) to install the piston pin bearing ... 85.0 mm (3.35 in)(3) Bore in bearing for piston pin (new) ... 50.830 0.008 mm (2.0012 .0003 in) Diameter of piston pin (new) ... 50.795 0.005 mm (1.9998 .0002 in)Thoroughly lubricate piston pin with clean engine oil prior to inserting into piston group and rod assembly.Maximum permissible clearance between bearing and piston pin (worn) ... 0.25 mm (.010 in)(4) Bearing joint must be assembled at either location on centerline through the connecting rod bore ... 5°Make reference to Special Instruction, Form No. SMHS7295 for use of pin bearing removal and installation tools and procedures.(5) Distance between center of bearings ... 261.62 0.05 mm (10.300 .002 in)(6) Bore in connecting rod for bearing with nuts tightened to specifications (8) ... 96.200 0.013 mm (3.7874 .0005 in)(7) Location for etching cylinder number on connecting rod and cap. Rods and caps are to be marked with numbers 1 through 6 on the same side of the rod as the bearing tab slots.(8) Tighten connecting rod bolts as follows: a. Before installing bolts, lubricate bolt threads and seating faces of the caps with 2P2506 Thread Lubricant.b. Tighten each bolt to ... 90 8 N m (66 6 lb ft)c. Put an alignment mark on each cap and bolt.d. Tighten each bolt an additional ... 90 5° (1/4 turn)(9) Bore in bearing for crankshaft rod journal ... 90.112 0.028 mm (3.5477 .0011 in) Clearance between bearing and crankshaft (new) ... 0.062 to 0.160 mm (.0024 to .0063 in)Maximum permissible clearance between bearing and crankshaft (worn) ... 0.20 mm (.008 in) Bearings are available in 0.63 mm (.025 in) and 1.27 mm (.050 in) smaller than original size.