Rating:

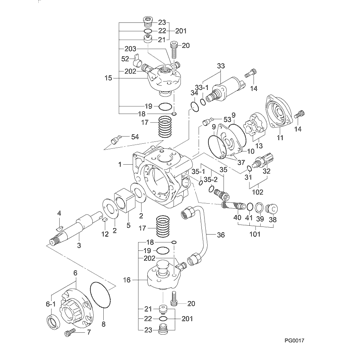

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$62.99

26 Mar 2023

CA: New_power

TOTMOX Fuel Pump Pressure Regulator Valve Compatible with Nissan X-Trail Almerea Navara Cabstar Murano Pathfinder Primera Tino

TOTMOX 【Practical Function】The fuel pump pressure regulator valve is designed to control or adjust the idling speed, effectively to reduce the consumption of fuel and to ensure that the engine runs steadily. || 【Durability】The valve is made of high quality material, as well as meets OEM standards, so it is stainless, durable and has long service life. || 【Easy to Install】Easy to install without any other modifications, saving your time and energy. || 【Good Replacement】Part numbers 294009-0120, 819185, 98043686, 0819185, 294200-06, 2942000660, RF5C13800A, RF5C13800B, RF5C13800C, 16700AW403, A6860-AW420, A6860AW420, A6860-AW42B, 2942000660, 97313862, 294000-0071, RF5C13800B, RFY013H50B, RF5C13800A, RF5C13800B, 16700-ES60A, RF5C13800C, 8-97313861, 16600-ES60, RF5C13H50A, RF5C13H50B, 16600-BN80, 16600-BN82, 16600-EB30, 294000-0473, 16600-AW40, 16600-AW42, 294000-0259, 294000-0265, 294000-0374, 294000-0075, 294000-0123, 294000-0163 || 【Wide Application】The fuel pump suction control valve can be Compatible with Nissan X-TRAIL ALMEREA NAVARA CABSTAR MURANO PATHFINDER PRIMERA TINO.

TOTMOX 【Practical Function】The fuel pump pressure regulator valve is designed to control or adjust the idling speed, effectively to reduce the consumption of fuel and to ensure that the engine runs steadily. || 【Durability】The valve is made of high quality material, as well as meets OEM standards, so it is stainless, durable and has long service life. || 【Easy to Install】Easy to install without any other modifications, saving your time and energy. || 【Good Replacement】Part numbers 294009-0120, 819185, 98043686, 0819185, 294200-06, 2942000660, RF5C13800A, RF5C13800B, RF5C13800C, 16700AW403, A6860-AW420, A6860AW420, A6860-AW42B, 2942000660, 97313862, 294000-0071, RF5C13800B, RFY013H50B, RF5C13800A, RF5C13800B, 16700-ES60A, RF5C13800C, 8-97313861, 16600-ES60, RF5C13H50A, RF5C13H50B, 16600-BN80, 16600-BN82, 16600-EB30, 294000-0473, 16600-AW40, 16600-AW42, 294000-0259, 294000-0265, 294000-0374, 294000-0075, 294000-0123, 294000-0163 || 【Wide Application】The fuel pump suction control valve can be Compatible with Nissan X-TRAIL ALMEREA NAVARA CABSTAR MURANO PATHFINDER PRIMERA TINO.

$57.00

26 May 2020

-: -

Fuel Pump Suction Control Valve 226701194R for Vauxhall Astra Combo Corsa Meriva 2001-2011

[OEM Part Number] 2942000660,2940090120,226701194R, A6860AW420,A6860AW42B,294000-0040, 294000-0041,294000-0042,294000-0043, 294000-0044,294000-0059,294000-0075 || [OEM Part Number] 294000-0121,294000-0122,294000-0123, 294000-0163,294000-0259,294000-0265, 294000-0374,294000-0470,294000-0471, 294000-0473,294009-0120,294200-0660, A6860-AW420,A6860-AW42B || [Application Vehicle] Nissan Almera Cabstar Murano Navara 2002-. || [Application Vehicle] Nissan Pathfinder Primera Tino X-trail 2005-. || [Application Vehicle] Vauxhall Astra Combo Corsa Meriva 2001-2011.

[OEM Part Number] 2942000660,2940090120,226701194R, A6860AW420,A6860AW42B,294000-0040, 294000-0041,294000-0042,294000-0043, 294000-0044,294000-0059,294000-0075 || [OEM Part Number] 294000-0121,294000-0122,294000-0123, 294000-0163,294000-0259,294000-0265, 294000-0374,294000-0470,294000-0471, 294000-0473,294009-0120,294200-0660, A6860-AW420,A6860-AW42B || [Application Vehicle] Nissan Almera Cabstar Murano Navara 2002-. || [Application Vehicle] Nissan Pathfinder Primera Tino X-trail 2005-. || [Application Vehicle] Vauxhall Astra Combo Corsa Meriva 2001-2011.

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

29400-00473

PUMP ASSY, SUPPLY

1008--1011

16700ES60E

NISSAN MOTOR

Include in ##:

29400-00473

as PUMP ASSY, SUPPLY

Cross reference number

Part num

Firm num

Firm

Name

29400-00473

16700ES60E

PUMP ASSY, SUPPLY

Information:

2. Remove nuts (1) from studs for main bearing caps (2).3. Remove the main bearing caps.4. Install rubber hose over each of the two studs at both ends of the block. This will protect the crankshaft during removal and installation. 5. Remove the crankshaft from the cylinder block. Weight of crankshaft is 300 lb. (136 kg).6. Remove the main bearings from cylinder block and main bearing caps.

If main bearings are not replaced, old bearings must be installed in same location from which they were removed.

Install Crankshaft

1. Put timing marks (1) on all timing gears in alignment.2. Clean surfaces for bearings in cylinder block. Install upper halves of bearings in block. Put clean oil on bearings.

If replacement of the bearings is not made, old bearings must be installed in same location from which they were removed.

3. Clean bearing caps, and install lower halves of bearings in caps. 4. Fasten a hoist to crankshaft and put it into place in the block with "V" mark on crankshaft gear in alignment with "V" mark on cluster gear. 5. Check bearing clearance with wire (A). Install bearing caps, and tighten both nuts to 75 5 lb. ft. (101.7 6.8 N m). Put a mark across the nuts and studs, and turn nuts an additional 120° from mark. Remove caps and check thickness of wire (A) to find bearing clearance. Bearing clearance must be .0035 to .0066 in. (0.089 to 0.168 mm) for new parts. Maximum permissible clearance for used parts is .010 in. (0.25 mm).6. Put clean oil on threads of studs, face of nuts, and lower halves of bearings. Put bearing caps in their respective positions with number on cap same as number on block, and groove in bearing cap on same side as groove in cylinder block. Install nuts and tighten to 75 5 lb.ft. (101.7 6.8 N m). Put a mark across the nuts and studs, and turn nuts an additional 120° from mark. 7. Use indicator group (B) to check the crankshaft end plate as controlled by lower bearing of No. 7 bearing cap. End play with new parts should be .006 to .018 in. (0.15 to 0.46 mm). Maximum permissible end play with used parts is .035 in. (0.89 mm).end by: a) install flywheel housingb) install front coverc) install pistonsd) install engine and torque divider

If main bearings are not replaced, old bearings must be installed in same location from which they were removed.

Install Crankshaft

1. Put timing marks (1) on all timing gears in alignment.2. Clean surfaces for bearings in cylinder block. Install upper halves of bearings in block. Put clean oil on bearings.

If replacement of the bearings is not made, old bearings must be installed in same location from which they were removed.

3. Clean bearing caps, and install lower halves of bearings in caps. 4. Fasten a hoist to crankshaft and put it into place in the block with "V" mark on crankshaft gear in alignment with "V" mark on cluster gear. 5. Check bearing clearance with wire (A). Install bearing caps, and tighten both nuts to 75 5 lb. ft. (101.7 6.8 N m). Put a mark across the nuts and studs, and turn nuts an additional 120° from mark. Remove caps and check thickness of wire (A) to find bearing clearance. Bearing clearance must be .0035 to .0066 in. (0.089 to 0.168 mm) for new parts. Maximum permissible clearance for used parts is .010 in. (0.25 mm).6. Put clean oil on threads of studs, face of nuts, and lower halves of bearings. Put bearing caps in their respective positions with number on cap same as number on block, and groove in bearing cap on same side as groove in cylinder block. Install nuts and tighten to 75 5 lb.ft. (101.7 6.8 N m). Put a mark across the nuts and studs, and turn nuts an additional 120° from mark. 7. Use indicator group (B) to check the crankshaft end plate as controlled by lower bearing of No. 7 bearing cap. End play with new parts should be .006 to .018 in. (0.15 to 0.46 mm). Maximum permissible end play with used parts is .035 in. (0.89 mm).end by: a) install flywheel housingb) install front coverc) install pistonsd) install engine and torque divider