Rating:

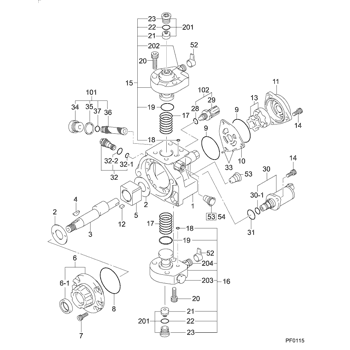

Information pump assy, supply Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump Compatible with Perkins Engine 404D 404D-22 404D-22T 404D-22TA 404C-22 404C-22T Compatible with New Holland 3415 TC35DA TC40DA TC48DA 104135-4032 1041354032

KoovDem Part Number: RE507959 294000-0059 || Item Type: Fuel Injection Pump || Compatible with various John Deere backhoe loaders, such as the 310K, 310SK, 315SK, 410J, 410K, 710J, and 710K, this product is versatile and adaptable to meet a variety of construction needs. || This product is specifically tailored to fit various John Deere dozer crawler models such as the 650J, 700J, 750J, 764, and 850J. Its design ensures seamless compatibility and integration with these machines, promoting efficient performance and effortless operation. Whether you need replacement components or enhancements, this product is a dependable option to keep your John Deere dozer crawler running smoothly and effectively.

KoovDem Part Number: RE507959 294000-0059 || Item Type: Fuel Injection Pump || Compatible with various John Deere backhoe loaders, such as the 310K, 310SK, 315SK, 410J, 410K, 710J, and 710K, this product is versatile and adaptable to meet a variety of construction needs. || This product is specifically tailored to fit various John Deere dozer crawler models such as the 650J, 700J, 750J, 764, and 850J. Its design ensures seamless compatibility and integration with these machines, promoting efficient performance and effortless operation. Whether you need replacement components or enhancements, this product is a dependable option to keep your John Deere dozer crawler running smoothly and effectively.

IMIFAFTAbT RE507959 RE527528 294000-0059 Fuel Injection Pump Fits For John Deere 4.5L 6.8L 4045 6068 6045 Engine 120D 160DLC 200DLC 250GLC 290GLC E300LC 6330 6430 7630 9560STS

IMIFAFTAbT Part Name:Fuel Injection Pump RE507959 RE527528 || Part Number:RE507959 RE527528 294000-0059 294000-0050 294000-0051 294000-0052 294000-0053 294000-0055 || APPlication: Compatible For John Deere 4045 4.5L Engine for John Deere 6068 6.8L Engine for John Deere 6045 Engine || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

IMIFAFTAbT Part Name:Fuel Injection Pump RE507959 RE527528 || Part Number:RE507959 RE527528 294000-0059 294000-0050 294000-0051 294000-0052 294000-0053 294000-0055 || APPlication: Compatible For John Deere 4045 4.5L Engine for John Deere 6068 6.8L Engine for John Deere 6045 Engine || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

RE507959 294000-0059 RE527528 Fuel Injection Pump for John Deere 4.5L 6.8L 4045 6068 6045 Engine 7520 Tractor 120D 130G 160DLC 200DLC 210G 240DLC E210LC E240LC E300LC Excavator

RPJFCPCS 🚜Part Number: RE507959 RE527528 294000-0059 294000-0050 294000-0051 294000-0052 294000-0053 294000-0055 || 🚜Engine Model: for John Deere 4045 4.5L Engine; for John Deere 6068 6.8L Engine, for John Deere 6045 Engine || 🚜Application: Backhoe Loader 310K 310SK 315SK 410J 410K 710J 710K; Dozer 650J 700J 750J 764 850J; Excavator 120D 130G 160DLC 200DLC 210G 240DLC 250GLC 270DLC 290GLC E210LC E240LC E300LC; Grader Motor 670C 670D; Loader 210K 444K 524K 544K 624J 624K 644K WL56 335D 437D || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. Thank you for your support and understanding! || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

RPJFCPCS 🚜Part Number: RE507959 RE527528 294000-0059 294000-0050 294000-0051 294000-0052 294000-0053 294000-0055 || 🚜Engine Model: for John Deere 4045 4.5L Engine; for John Deere 6068 6.8L Engine, for John Deere 6045 Engine || 🚜Application: Backhoe Loader 310K 310SK 315SK 410J 410K 710J 710K; Dozer 650J 700J 750J 764 850J; Excavator 120D 130G 160DLC 200DLC 210G 240DLC 250GLC 270DLC 290GLC E210LC E240LC E300LC; Grader Motor 670C 670D; Loader 210K 444K 524K 544K 624J 624K 644K WL56 335D 437D || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. Thank you for your support and understanding! || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Cross reference number

Part num

Firm num

Firm

Name

29400-00059

PUMP ASSY, SUPPLY

Information:

(3) Torque for locknut for valve adjustment screw ... 30 4 N m (22 3 lb ft)(4) Torque for locknut for bridge adjustment screw ... 30 4 N m (22 3 lb ft)(5) Valve lash: Intake valves ... 0.38 mm (.015 in)Exhaust valves ... 0.76 mm (.030 in)(6) Height to top of dowel ... 53.3 0.5 mm (2.10 .02 in)(7) Diameter of dowel ... 11.008 0.003 mm (.4334 .0001 in) Bore in bridge for dowel ... 11.13 0.05 mm (.438 .002 in)Bore in head for dowel ... 10.968 0.020 mm (.4318 .0008 in)(8) Diameter of valve lifter ... 27.896 0.013 mm (1.0983 .0005 in) Bore in block for valve lifter ... 27.953 0.019 mm (1.1005 .0008 in) See Guideline For Reusable Parts; Salvage Of Lifter Bores In 3400 Family Engines, Form No. SEBF8069 for the procedure, tooling and specifications needed to install 4W4588 Sleeves for salvage of the lifter bores in the cylinder block.(9) Guide springs must not be used again. Always install new guide springs. (10) 2N7229 Spring: Length under test force ... 74.2 mm (2.92 in)Test force ... 45 to 53 N (10 to 12 lb)Free length after test ... 114.3 mm (4.50 in)Outside diameter ... 29.7 mm (1.17 in)(11) Dowel length above top surface of rocker shaft support to be ... 12.7 1.0 mm (.50 .04 in)(12) Clearance for rocker arms (both ends) ... 0.30 to 1.40 mm (.012 to .055 in)(13) Use 2N7228 Washer as needed to get clearance (12). There must be a minimum of one 2N7228 Washer at each end of the rocker arm shaft. The bridge should be checked and/or adjusted each time the valves are adjusted. To check for wear use a dial indicator to measure the amount of wear on the bridge seat. Make sure the contact point on the dial indicator is small enough in diameter to get an accurate measurement. (A) Minimum dimension after reconditioning ... 16.51 mm (.650 in)(B) Allowable wear before reconditioning ... 0.13 mm (.005 in).Inspect the bridge seats for wear. Use the bridge again if the wear is 0.13 mm (.005 in) or less. When the wear seat is worn more than the allowable limit, the worn surface of the seat can be ground flat. The maximum amount of material that can be removed is 0.38 mm (.015 in). If the seat cannot be made flat, replace the bridge. Reconditioning of the wear seat can only be done once.