Rating:

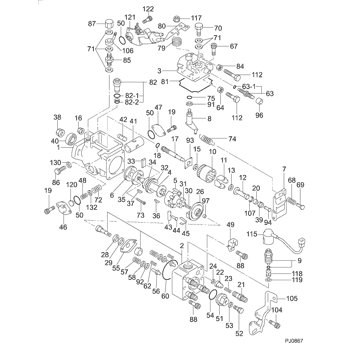

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL 1DZ

Engine

1DZ

Serial start-end

1301-

Info

Injector Nozzle

093500-8130

Injector nozzle:

0935008130

KIT List:

Part name

Kit1

Kit2

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$1,009.60

10 Aug 2024

CN: GEMMOE

22100-UC240 22100-UC220 196000-6200 Diesel Fuel Injection Pump

Thcbme Part Number : 196000-6200 22100-UC220 22100-UC240 || Diesel Fuel Injection Pump 196000-6200 22100-UC220 22100-UC240 || High efficiency: for a stable and efficient fuel supply || Ideal replacement: Precision engineered to match specific vehicles || Ensure fit: To make sure this part fits your exact vehicle

Thcbme Part Number : 196000-6200 22100-UC220 22100-UC240 || Diesel Fuel Injection Pump 196000-6200 22100-UC220 22100-UC240 || High efficiency: for a stable and efficient fuel supply || Ideal replacement: Precision engineered to match specific vehicles || Ensure fit: To make sure this part fits your exact vehicle

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

19600-06200

PUMP ASSY, INJECTI

22100-UC220

TOYOTA

Include in ##:

19600-06200

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

19600-06200

22100-UC22

PUMP ASSY, INJECTI

1960006200

22100-UC220

TOYOTA

PUMP ASSY, INJECTI

Information:

Introduction

This special instruction provides information for the installation of the Caterpillar Diesel Particulate Filter (DPF) on a 966G Wheel Loader.Before performing this procedure, you must read and understand the guidelines in Special Instruction, REHS1807, "Installation Guide for Particulate Trap Exhaust Filters" for important installation, general maintenance, testing, and cleaning information that is not included in this publication. Understanding the alarm operation and the maintenance requirements by the owner and the operator is important.The Caterpillar DPF system includes a particulate exhaust filter, a diagnostics module, a thermocouple, and installation parts. The DPF replaces the muffler. The DPF requires additional brackets and modifications for the installation.The Caterpillar DPF is used to reduce particulate matter, carbon monoxide, and hydrocarbon from diesel engine exhaust through catalytic oxidation and filtration. These filters are self-regenerating, so the filters do not need to be replaced. The filters will periodically burn off the accumulated soot. For this application, the following requirements must be met. Refer to the EPA web site for the latest verification requirements for Caterpillar Diesel Particulate Filter installations.Refer to Special Instruction, REHS1807, "Installation Guide for Particulate Trap Exhaust Filters".

Ultra-Low Sulfur Diesel Fuel must be used. Ultra-Low Sulfur Diesel Fuel must have an average sulfur content of 15 ppm. The maximum sulfur content of the fuel must not exceed 30 parts per million (ppm).

The Exhaust Temperature of the engine must be greater than 240 °C (464 °F) for at least 40% of the time.

The ratio of emissions of Oxides of Nitrogen (NOx) to Particulate Matter must be a minimum of 20. This ratio should be higher for applications that involve a lower temperature. This technology is currently applicable to 1996 and newer engines.

The engine should be well maintained and not consuming oil at an excessive rate (greater than the engine specification).Engine oil with a high API category rating is the best engine oil. Acceptable oil grades for the Diesel Particulate Filter are CH-4, CI-4, and CJ-4. Diesel Particulate Filter CI-4 oil is superior to CH-4 oil. CJ-4 oil is superior to CI-4 oil. CJ-4 oil is highly recommended due to a low ash specification that results in better Diesel Particulate Filter performance.

Illustration 1 g01035610

Typical Operating Range for a DPFRefer to Illustration 1 for the typical operating range of a DPF.Note: Do not perform any procedure in this Special Instruction until the information has been read and thoroughly understood.ReferenceRefer to Special Instruction, REHS1807, "Installation Guide for Particulate Trap Exhaust Filters".Safety

Diesel Particulate Filters (DPF) are not applicable to all engines. A Diesel Particulate Filter should typically not be applied to engines that are not regulated. Diesel Particulate Filters are meant for usage on only diesel engines. This technology does not apply to gas engines. Consult with Caterpillar in order to determine if a Diesel Particulate Filter can be used on your engine.

Personal injury or death can result from sudden machine movement.Sudden movement of the machine can cause injury to persons on or near the machine.To prevent injury or death, make sure that the area around the machine

This special instruction provides information for the installation of the Caterpillar Diesel Particulate Filter (DPF) on a 966G Wheel Loader.Before performing this procedure, you must read and understand the guidelines in Special Instruction, REHS1807, "Installation Guide for Particulate Trap Exhaust Filters" for important installation, general maintenance, testing, and cleaning information that is not included in this publication. Understanding the alarm operation and the maintenance requirements by the owner and the operator is important.The Caterpillar DPF system includes a particulate exhaust filter, a diagnostics module, a thermocouple, and installation parts. The DPF replaces the muffler. The DPF requires additional brackets and modifications for the installation.The Caterpillar DPF is used to reduce particulate matter, carbon monoxide, and hydrocarbon from diesel engine exhaust through catalytic oxidation and filtration. These filters are self-regenerating, so the filters do not need to be replaced. The filters will periodically burn off the accumulated soot. For this application, the following requirements must be met. Refer to the EPA web site for the latest verification requirements for Caterpillar Diesel Particulate Filter installations.Refer to Special Instruction, REHS1807, "Installation Guide for Particulate Trap Exhaust Filters".

Ultra-Low Sulfur Diesel Fuel must be used. Ultra-Low Sulfur Diesel Fuel must have an average sulfur content of 15 ppm. The maximum sulfur content of the fuel must not exceed 30 parts per million (ppm).

The Exhaust Temperature of the engine must be greater than 240 °C (464 °F) for at least 40% of the time.

The ratio of emissions of Oxides of Nitrogen (NOx) to Particulate Matter must be a minimum of 20. This ratio should be higher for applications that involve a lower temperature. This technology is currently applicable to 1996 and newer engines.

The engine should be well maintained and not consuming oil at an excessive rate (greater than the engine specification).Engine oil with a high API category rating is the best engine oil. Acceptable oil grades for the Diesel Particulate Filter are CH-4, CI-4, and CJ-4. Diesel Particulate Filter CI-4 oil is superior to CH-4 oil. CJ-4 oil is superior to CI-4 oil. CJ-4 oil is highly recommended due to a low ash specification that results in better Diesel Particulate Filter performance.

Illustration 1 g01035610

Typical Operating Range for a DPFRefer to Illustration 1 for the typical operating range of a DPF.Note: Do not perform any procedure in this Special Instruction until the information has been read and thoroughly understood.ReferenceRefer to Special Instruction, REHS1807, "Installation Guide for Particulate Trap Exhaust Filters".Safety

Diesel Particulate Filters (DPF) are not applicable to all engines. A Diesel Particulate Filter should typically not be applied to engines that are not regulated. Diesel Particulate Filters are meant for usage on only diesel engines. This technology does not apply to gas engines. Consult with Caterpillar in order to determine if a Diesel Particulate Filter can be used on your engine.

Personal injury or death can result from sudden machine movement.Sudden movement of the machine can cause injury to persons on or near the machine.To prevent injury or death, make sure that the area around the machine