Rating:

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

INDUSTRIAL S6S-DT

Engine

S6S-DT

Serial start-end

0307-

Info

Injector Nozzle

093500-7600

Injector nozzle:

0935007600

KIT List:

Part name

Kit1

Kit2

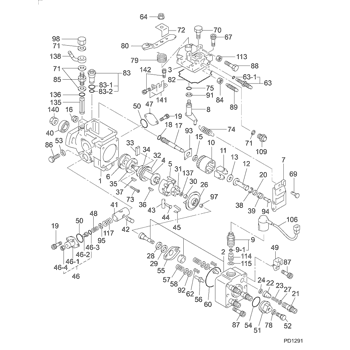

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

19600-04800

PUMP ASSY, INJECTI

Include in ##:

19600-04800

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

19600-04800

PUMP ASSY, INJECTI

Information:

Illustration 1 g00567869

ETS Junction Box with oil pressure protection (OP), water temperature protection (WT), and overspeed protection (OS) that does not require a switchgear for use on 3200 through 3400 Engines (1) Terminal strips (TS) (2) Wiring harness (3) Electronic speed switch (ESS) (4) Junction box (5) Identification foil (6) Jumper between terminals (TS-2) and (TS-3) (7) Jumper between terminals (TS-3) and (TS-4) (8) Emergency stop switch (ES) (9) Time delay relay (TD) (10) Jumper between terminals (TS-27) and (TS-28) (11) Jumper between terminals (TS-28) and (TS-29) (12) Jumper between terminals (TS-30) and (TS-31) (13) Slave relay (SR1) (14) Slave relay (SR2) for the air shutoff solenoid (ASOS) (if equipped) (15) Grommet assembly for engine oil pressure switches (16) Start/stop switch (SSS) (17) Circuit breakers (18) Engine oil pressure switch (OPS1) (19) Mounting brackets for grommet assemblies

Illustration 2 g00290530

ETS Junction Box with oil pressure protection (OP), water temperature protection (WT), and overspeed protection (OS) that does not require a switchgear for use on 3500 Engines (1) Terminal strips (TS) (2) Wiring harness (3) Electronic speed switch (ESS) (4) Junction box (5) Identification foil (6) Jumper between terminals (TS-2) and (TS-3) (7) Jumper between terminals (TS-3) and (TS-4) (8) Emergency stop switch (ES) (9) Time delay relay (TD) (10) Jumper between terminals (TS-27) and (TS-28) (11) Jumper between terminals (TS-28) and (TS-29) (12) Jumper between terminals (TS-30) and (TS-31) (13) Slave relay (SR1) (14) Slave relay (SR2) for the air shutoff solenoid (ASOS) (if equipped) (15) Slave relay (SR3) for starting aid switch (if equipped) (16) Diode for electric governor actuator (if equipped) (17) Grommet assembly for engine oil pressure switches (18) Start/stop switch (SSS) (19) Circuit breakers (20) Engine oil pressure switch (OPS1) (21) Mounting brackets for grommet assemblies (22) Engine oil pressure switch (OPS2) (if equipped)Introduction

The ETS Junction Box with oil pressure protection (OP), water temperature protection (WT), and overspeed protection (OS) that does not require a switchgear is a system that has full protection. The system has a junction box arrangement that is designed to monitor four functions:

Engine overspeed

Crank termination

Oil pressure

Coolant temperatureThe junction box includes the following components:

Electronic speed switch (ESS) (2)

Start/stop switch (SSS) (18) and (16)

Slave relay (SR1) (13)

Slave relay (SR2) (if equipped) with an air shutoff solenoid (ASOS) (14)

Oil pressure switch (OPS1) (18) and (20)

Oil pressure switch (OPS2) that is only in 3500 Engines (22)

Emergency stop switch (ES) (8)

Time delay relay (TD) (9) The components that are listed below operate with the junction box. The components are also mounted on the engine.

Fuel shutoff solenoid (FSOS)

Air shutoff solenoid (ASOS)

Water temperature switch (WTS)The following components must remain de-energized in order for the engine to run with the ETS electric protection system.

Slave relay (SR1)

Slave relay (SR2) (if equipped)

Fuel solenoid (FS)

Air shutoff solenoid (ASOS)Electrical Schematics And Wiring Diagrams

This manual contains the point-to-point wiring diagrams for the complete electric protection system and the junction box. Four types of electrical schematics for each electric protection system arrangement are shown in this service manual.

Junction box wiring diagram

IEC (International Electro-Technical Commission) schematic

JIC (Joint Industrial