Rating:

Information pump assy, injecti Denso

Product

Fuel Injection Pump

Vehicle engine

LAND CRUISER 1HZ

Engine

1HZ

Serial start-end

9804-

Info

Injector Nozzle

093500-6890

Manufacture:

22100-1C180 TOYOTA

Dim 1

3.2-3.45

Dim 2

5.8-6.0

Dim 3

0.19-0.39

Dim 4

Dim 5

Dim 6

Information

Injector nozzle:

0935006890

KIT List:

Part name

Kit1

Kit2

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

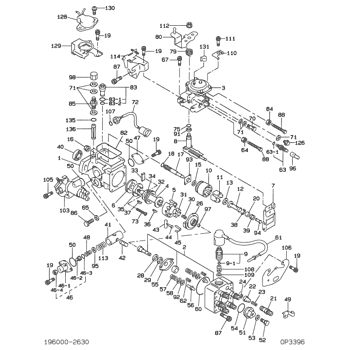

19600-02630

PUMP ASSY, INJECTI

22100-1C180

TOYOTA

Include in ##:

19600-02630

as PUMP ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

19600-02630

22100-1C18

PUMP ASSY, INJECTI

1960002630

22100-1C180

TOYOTA

PUMP ASSY, INJECTI

Information:

Crankshaft Turns1. Install the Electronic Control Analyzer and Programmer (ECAP) or the Digital Diagnostic Service Tool (DDT). See Electronic Troubleshooting, 3176 Vehicular Diesel Engine, Form No. SENR5137.2. Electronic Self Check. Check the electronics diagnostic lamp on the dash to determine if there are any faults in the engine electronics system. Repair or replace parts as needed. See Electronic Troubleshooting, 3176 Vehicular Diesel Engine, Form No. SENR5137.3. Check all wiring harness connectors. Connectors can be forced together with pins out of sequence.4. Check Cranking Speed Of Crankshaft. Using the ECAP or DDT, check the speed of the crankshaft while the starter is cranking. If the crankshaft speed is below 250 rpm, then proceed to item 5. If the crankshaft speed is above 250 rpm, then proceed to item 6. If no rpm is displayed, refer to Engine Test Procedure Number P-102 in Electronic Troubleshooting, 3176 Vehicular Diesel Engine, Form No. SENR5137.5. Possible Causes Of Low Cranking Speed:A. Low Battery Voltage Check battery voltage. If the voltage is less than 8 volts for a 12 volt system, or 16 volts for a 24 volt system, put a charge to the battery. If the battery will not hold a charge, load test the battery. Use the 4C4911 Battery Load Tester and make reference to Operating Manual, Form No. SEHS9249 for complete information on use of the 4C4911 Battery Load Tester.B. Defective Cable, Battery To Starter, Or Defective Connection With ignition switch in the START position, check the voltage at the connection of the battery cable to the starter. If there is no voltage, or if the voltage is low at this connection and there is good voltage at the battery, check for a defective cable or connection between the battery and the starter.C. Oil Too Thick For Free Crankshaft Rotation Refer to the Challenger 75 Operation And Maintenance Manual, Form No. SEBU6335 for the correct SAE grade oils for the ambient temperatures at which the engine is being operated. At temperatures below -23°C (-10°F), it may be necessary to warm the oil for free crankshaft rotation.D. Defective Starter Motor Remove and test. Make repairs as necessary or install a new starter motor.E. Extra Outside Loads. Damage to the power take-off equipment (if so equipped) and/or transmission can put extra load on the engine and prevent free rotation of the crankshaft. To check, disconnect the transmission and power take-off, and start the engine.F. Transmission Or Power Take-off Problem See 3176 Vehicular Diesel Engine Service Manual, Form No. SENR4960.G. Internal Engine ProblemDisassemble the engine and check all components for damage. See 3176 Vehicular Diesel Engine Disassembly And Assembly, Form No. SENR4965.6. Can Exhaust Smoke Be Seen While Starting?If exhaust smoke can be seen while starting the engine, then proceed to item 7. If exhaust smoke cannot be seen while starting the engine, then proceed to item 8.7. Possible Causes-Engine Will Not StartA. Cold Outside Temperatures If temperatures are at or below 0°C (32°F) it may be necessary to use starting aids. It